A lightweight container house made of foamed aluminum

A container and aluminum foam technology, which is applied in the direction of building types, special buildings, small buildings, etc., can solve the problems of no anti-theft, strong thermal conductivity of steel plates, short service life, etc., and achieve fire resistance, non-combustibility, and strong energy absorption , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

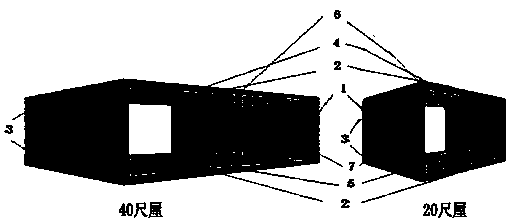

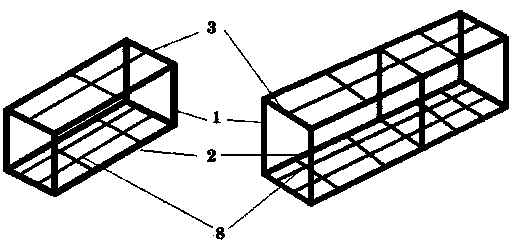

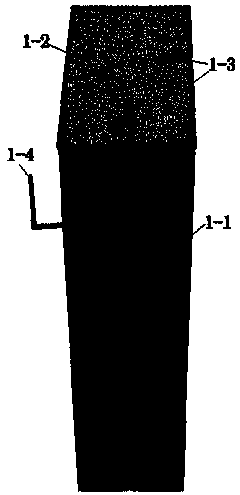

[0045] Figure 1-Figure 8 1 is the column, 2 is the top and bottom long beam, 3 is the top and bottom short beam, 4 is the top panel, 5 is the bottom panel, 6 is the long side panel, 7 is the short side panel, 8 is the dragon skeleton, 1 -1 is the column panel, 1-2 is the inner sandwich layer of the column, 1-3 is the column tongue and groove, 1-4 is the pull ring, 2-1 is the upper and lower panels of the long beam, 2-2 is the sandwich layer between the panels , 2-3 is the tongue and groove of the long beam, 3-1 is the upper and lower panels of the short beam, 3-2 is the sandwich layer between the panels, 3-3 is the tongue and groove of the short beam, 4-1 is the foamed aluminum alloy of 7.2㎏ Veneer / and its single-sided composite veneer, 4-2 is a 20-foot roof panel, 4-3 is a 40-foot roof panel, 5-1 is a foamed aluminum alloy veneer weighing 14.4㎏ / and its single-sided 5-2 is the bottom panel of a 20-foot house, 5-3 is the bottom panel of a 40-foot house, 6-1 is a 7.5㎏ foam alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com