Method for stoping of stocked ore in stope by adopting sublevel stoping method

A stage mine method and a technology for depositing ore, which is applied in ground mining, underground mining, special mining, etc., can solve the problems of ore resource loss, reduce the ore funnel, eyebrow blasting damage, etc., and achieve the improvement of ore recovery rate, The effect of reducing blasting unit consumption and increasing tax revenue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

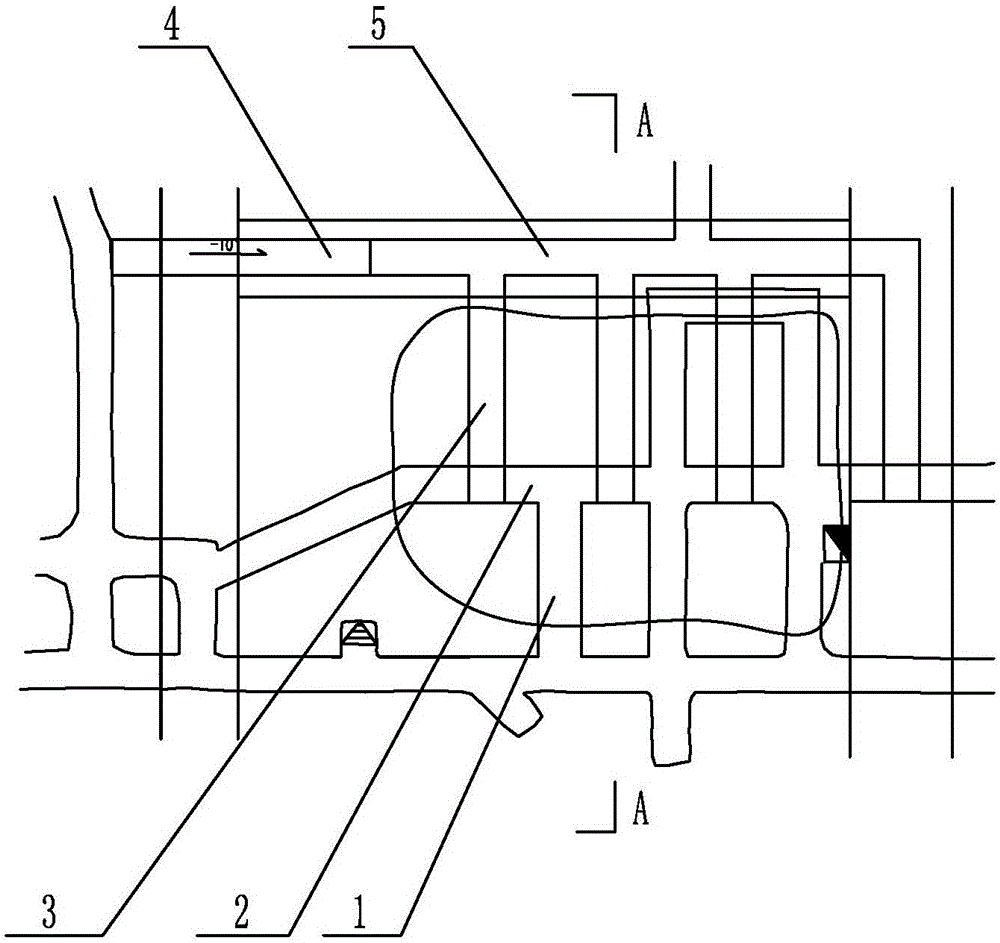

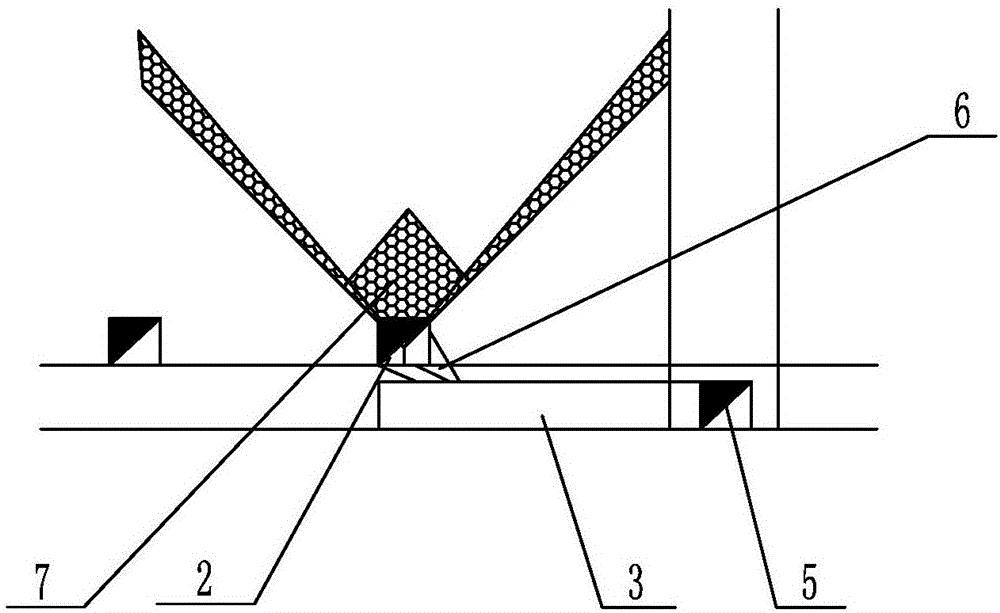

[0031] Area 520 of Beijinzhaobei Deposit is buried at -350m~-310m level, the roof is limestone, the floor is diorite, local skarn, and the ore rock structure is stable. The mining house adopts the mining method of stage mine. The length of the mine house is 36m, and the width is 24m. Existing production systems are utilized for mining, transportation, and upgrading, making full use of existing projects and reducing investment in new projects.

[0032] Firstly, construct a -10° slope road parallel to the center line of the original rock drilling at the roadway outside the vein of the 515 area at the -350m level to the -353.5m level, and construct a new 523 column inner roadway. In the horizontal entry within the -353.5m horizontal column, a number of new mining roadways are constructed perpendicular to the direction of the original rock drilling roads to the 520 original rock drilling roadways, and the new mining roadways are arranged alternately with the original mining roadwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com