Rail pressure regulating valve for common-rail system

A common rail system and regulating valve technology, applied in the field of rail pressure regulating valve, can solve the problems of poor transient response, complex control algorithm, large energy loss, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better illustrate the purpose and advantages of the present invention, the content of the invention will be further described below in conjunction with the accompanying drawings and examples.

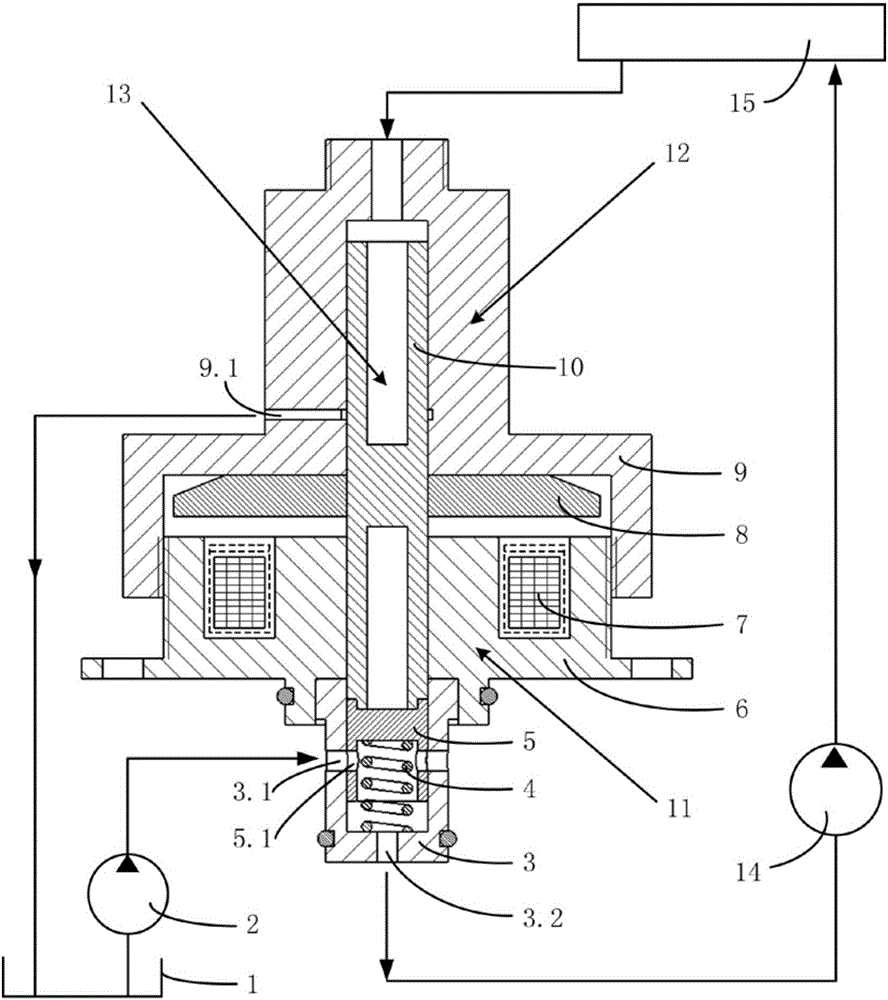

[0024] A rail pressure regulating valve 13 for a common rail system includes: a metering valve 11 and a feedback valve 12 .

[0025] The metering valve 11 is composed of a valve body 3, a spring 4, a valve core 5, a metering valve housing 6, an excitation coil 7 and a disc-shaped armature 8; Hole 3.2, oil inlet hole 3.1 is opened on the side wall; spring 4 is placed between valve body 3 and valve core 5, and is initially pre-compressed by valve core 5; valve core 5 is placed inside valve body 3, and can be rotated The valve core 5 is provided with a throttling hole 5.1, which matches the oil inlet hole 3.1, and the axial movement of the valve core 5 will change the through area between the oil inlet hole 3.1 and the throttle hole 5.1, thereby The opening of the valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com