Performance test bench for car air compressor

A technology of air compressors and test benches, applied in pump testing, mechanical equipment, machines/engines, etc., can solve the problems of low detection efficiency, achieve the effects of improving detection efficiency, convenient and fast operation, and reducing labor and detection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

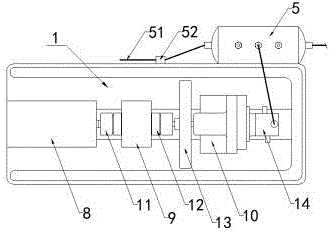

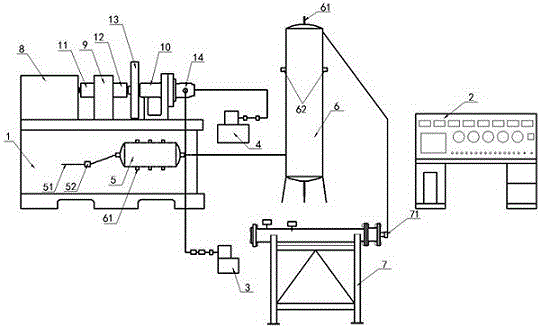

[0015] Depend on figure 1 , figure 2 Known, a kind of vehicle air compressor performance test bench, comprises workbench 1, control cabinet 2, oil supply device 3, water supply device 4, gas storage tank I5, gas storage tank II6, low pressure box 7, described control cabinet 2 is equipped with a control system, which controls the workbench 1, oil supply device 3, water supply device 4, gas storage tank Ⅰ5, gas storage tank Ⅱ6, and low-pressure box 7; the side of workbench 1 is equipped with gas storage tank Ⅰ5 , the gas storage tank I5 is connected with the gas storage tank II6, and the gas storage tank II6 is connected with the low-voltage box 7; the workbench 1 is provided with a driving motor 8, a torque sensor 9, and an air compressor fixture 10, and the driving motor 8 and the torque The sensors 9 are connected through the first coupling 11, the torque sensor 9 is connected with the balance wheel 13 through the second coupling 12, and the air compressor fixture 10 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com