An Intelligent Hydraulic Station

A hydraulic station and intelligent technology, applied in the field of hydraulic station, can solve the problems of large workpiece size error and low qualified rate of workpiece finished products, and achieve the effect of eliminating workpiece size error, safe operation of equipment and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Under normal circumstances, when processing workpieces, there may be iron filings or powder on the surface of the workpiece. Once there are iron filings or powder on the surface of the workpiece, the workpiece cannot be close to the workbench or processing platform during processing, and the processed workpiece The size will become larger or smaller, which is fatal for workpieces that require relatively high precision, especially for some workpieces that need to be sealed. Low precision means that there are gaps in the combination between each other, and the sealing effect cannot be achieved.

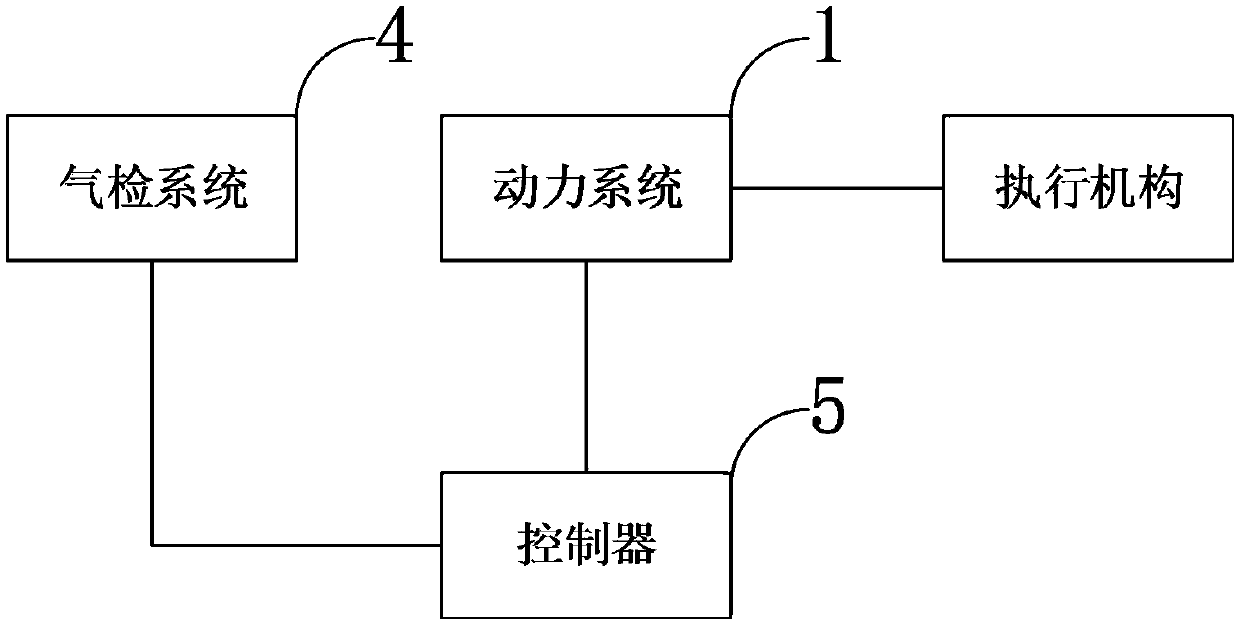

[0055] like figure 1 As shown, it is a structural representation of the intelligent hydraulic station of the present invention Figure 1 ; Wherein, the intelligent hydraulic station includes:

[0056] The power system 1 is connected with an external actuator to provide power for the actuator to process the workpiece;

[0057] The air detection system 4 detects the workpiece bef...

Embodiment 2

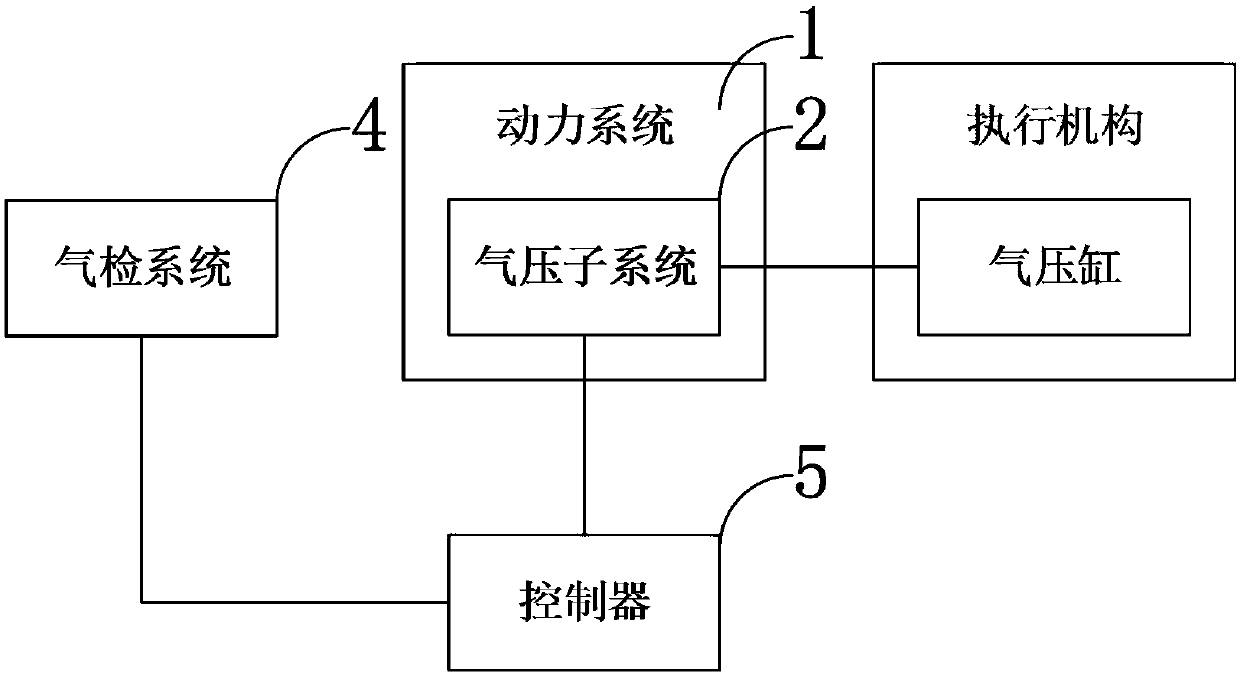

[0061] As the intelligent hydraulic station described above, the difference of this embodiment is that, as figure 2 As shown, the power system includes a pneumatic subsystem 2, which is connected with the pneumatic cylinder in the actuator to provide power for the pneumatic cylinder. In this way, the intelligent hydraulic station can provide power for the external pneumatic cylinder, increasing the application range of the intelligent hydraulic station.

Embodiment 3

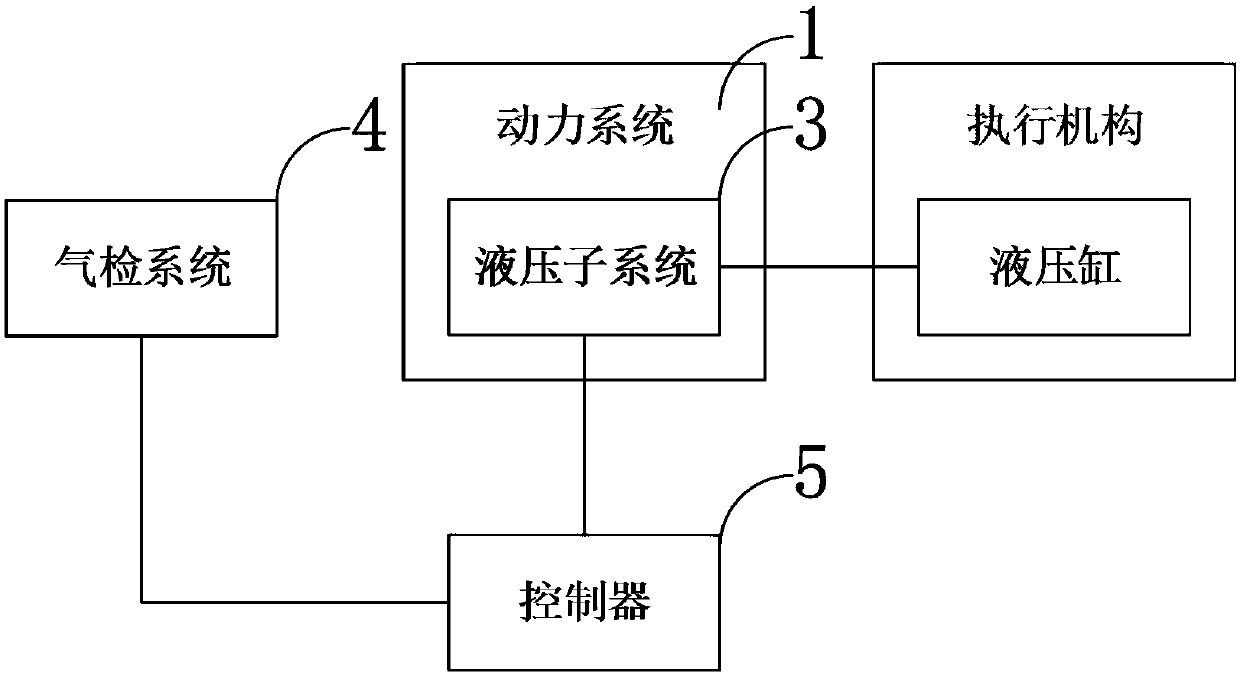

[0063] As the intelligent hydraulic station described above, the difference of this embodiment is that, as image 3 As shown, the power system includes a hydraulic subsystem 3, which is connected with the hydraulic cylinder in the actuator to provide power for the hydraulic cylinder. In this way, the intelligent hydraulic station can provide power for external hydraulic cylinders, increasing the application range of the intelligent hydraulic station.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com