A force limiting device with damping

A force-limiting and damping technology, applied in springs, shock absorbers, gas shock absorbers, etc., can solve the problems of high sealing performance requirements, difficult promotion and application, and high production costs, and achieve unique functions, promote internal force redistribution, powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

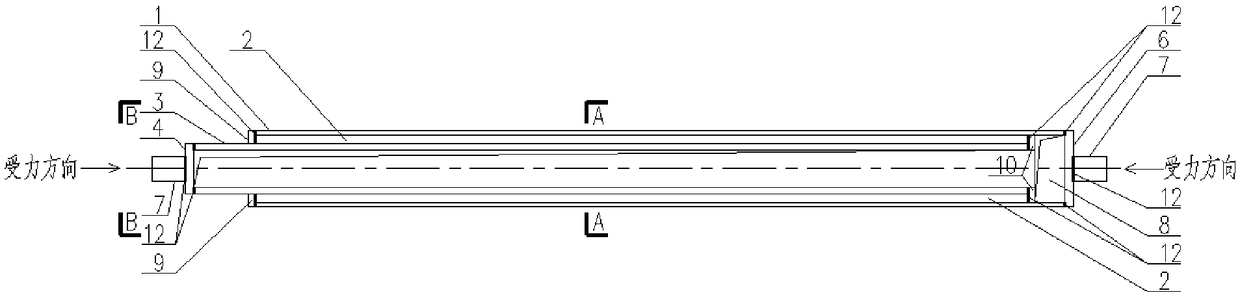

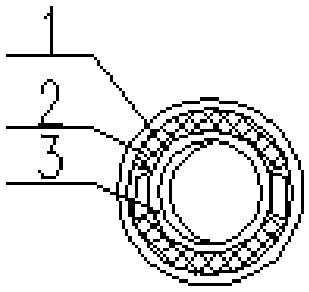

[0058] Such as Figure 1-3 As shown, the limiting force device with damping in this embodiment includes an outer tube 1 and an inner tube 3, the end of the outer tube 1 is connected with a base 6, and a part of the inner tube 3 extends from the head end of the outer tube 1 to the outer tube 1 Inside, the outer end of the inner tube 3 is connected with the upper cover 4, and the base 6 and the upper cover 4 are respectively connected with a connecting piece 7, which is connected to the main structure through the connecting piece 7 during use, and the connecting piece 7 can withstand pressure.

[0059] The limiting force device with damping of this embodiment also includes a metal damping unit 2, the metal damping unit 2 is located between the outer tube 1 and the inner tube 3, and is arranged along the axial direction of the outer tube 1 and the inner tube 3, and one end thereof is connected to the outer tube 3. The tube 1 is fixedly connected, and the other end is fixedly conn...

Embodiment 2

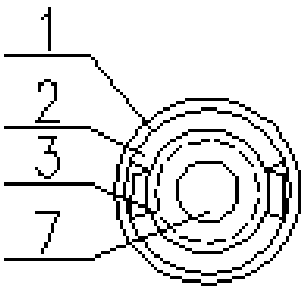

[0068] Such as Figure 4-6 As shown, the force limiting device with damping of this embodiment differs from Embodiment 1 in that:

[0069] In this embodiment, the metal damping unit 2 is four arc-shaped metal slats.

Embodiment 3

[0071] Such as Figure 7-9 As shown, the force limiting device with damping of this embodiment differs from Embodiment 1 in that:

[0072] In this embodiment, the metal damping unit 2 is a circular metal tube.

[0073] Embodiments 1-3 provide that the outer sleeve 1 and the inner tube 3 are circular metal tubes, and the metal damping unit 2 is in the form of arc-shaped metal laths or circular tubes. When in use, the outer sleeve 1 and the inner tube 3 The form is not limited to circular metal tubes, and rectangular metal tubes can also be used, and the metal damping unit 2 can also be in the form of metal laths or rectangular tubes, see embodiments 5-7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com