A top-feed steel storage silo cable-type beamless membrane roof structure and storage silo structure

A cable-type and thin-film storage warehouse technology, applied in the field of industrial building structures, can solve the problems of increasing the height of the factory building, increasing the overall design index and construction investment of the factory building, and achieving the reduction of steel consumption, optimization of design indicators and construction investment, Effect of reducing load and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

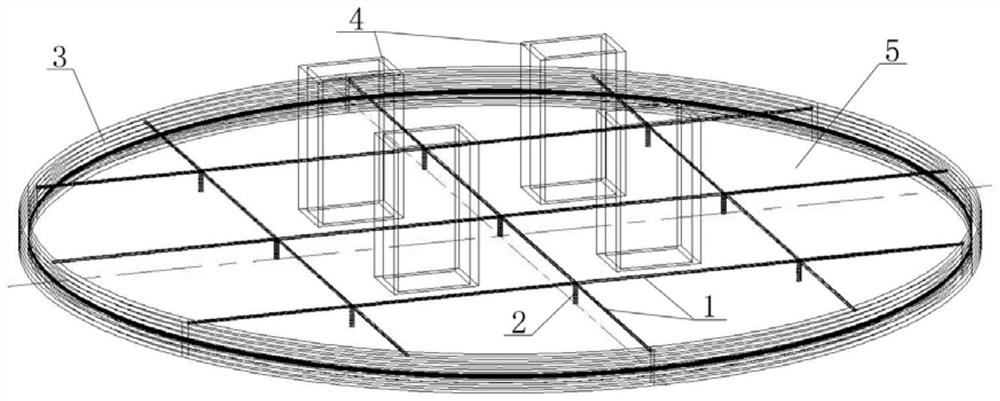

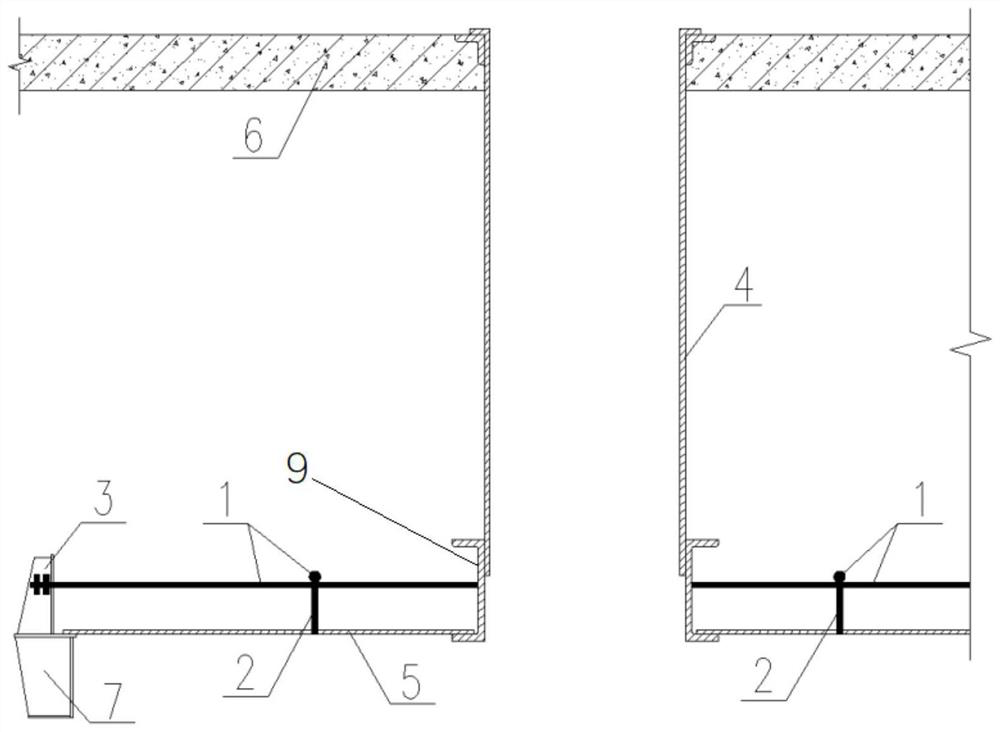

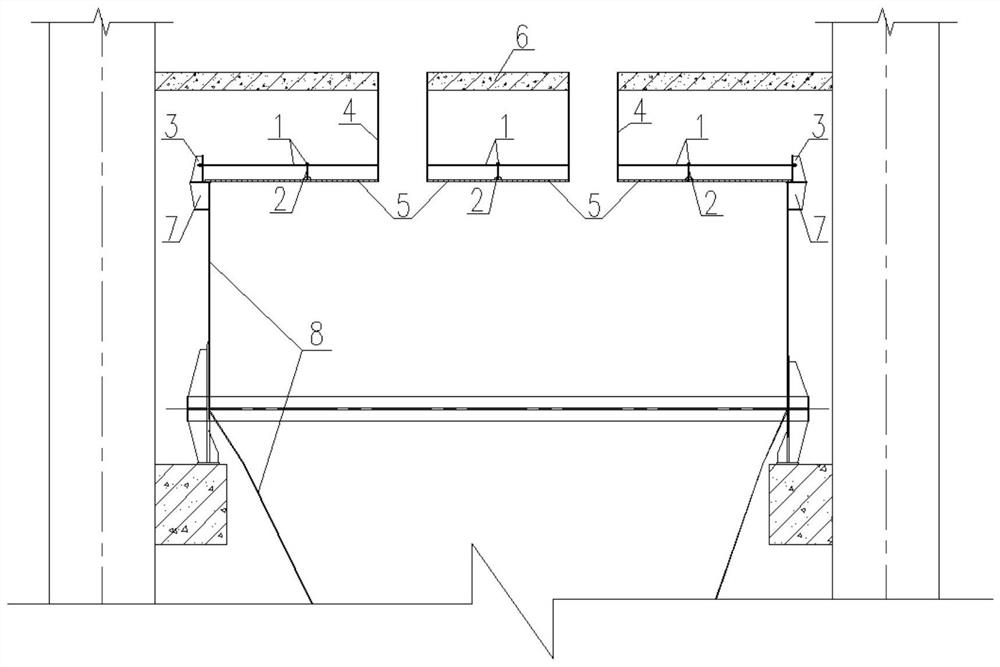

[0040] Attached below figure 1 - attached image 3 The top cover structure disclosed in this embodiment is further described;

[0041] Refer to attached Figure 1-Figure 2 As shown, a cable-type beamless membrane roof for a top-feed steel storage bin includes: a membrane roof 5 , a cable 1 , a sling 2 , an upturned support ring beam 3 and a drop tube 4 .

[0042] The membrane roof 5 cancels the upturned steel beam of the traditional steel roof, and can adopt thin steel plate or membrane structure of other materials. Thin steel plate refers to a steel plate with a thickness between 0.2 and 4mm produced by hot rolling or cold rolling.

[0043] Lay cables 1 are arranged above the film top cover 5, and the film top cover 5 is arranged horizontally. The drag cables 1 are arranged in a direction parallel to the film top cover 5. Cables and transverse stay cables, longitudinal stay cables and transverse stay cables are arranged in a staggered manner, and each longitudinal stay ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com