An energy-dissipative stiffened steel polymer interlayer pipe and its manufacturing process

A polymer, interlayer technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of poor impact resistance, poor fatigue resistance, low structural ductility, etc., and achieve good ductility. , Prevent buckling damage, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

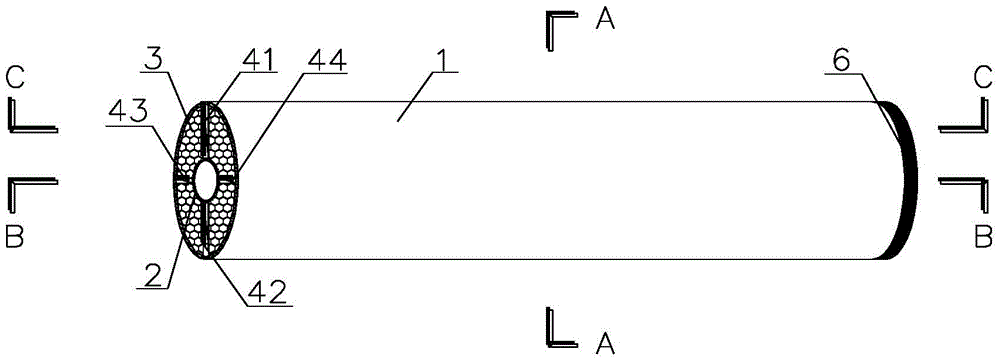

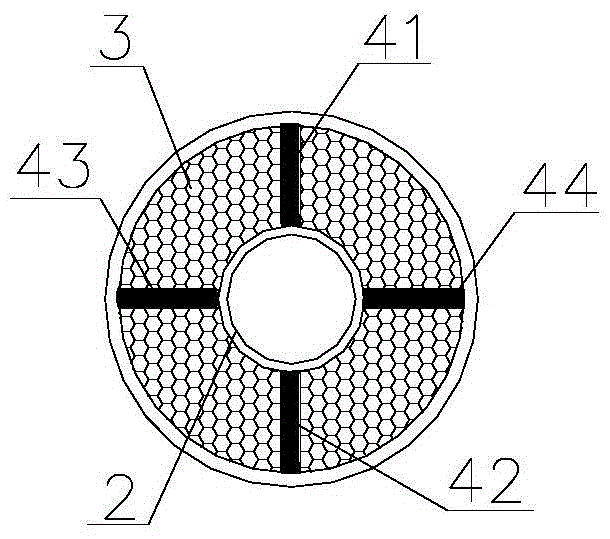

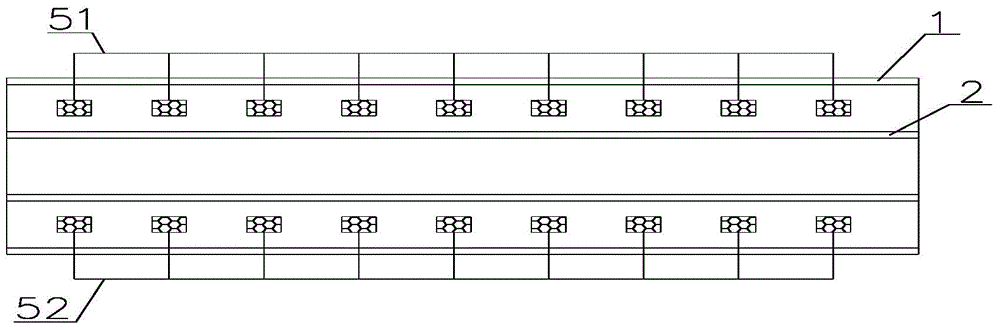

[0032] refer to Figure 1 to Figure 5 , an energy-dissipative stiffened steel polymer sandwich tube, comprising a metal outer tube 1, a metal inner tube 2, n pieces of stiffening plates, a cover plate 6 and a core material 3, where n is an integer greater than or equal to 3, and the metal outer tube 1 Concentrically arranged in the metal inner tube 2, the bottom of the stiffening plate is connected to the outer wall of the metal inner tube 2, and the top of the stiffening plate is connected to the inner wall of the metal outer tube 1. Viewed from the cross section , the n pieces of stiffening plates are arranged on the ring between the metal inner tube and the metal outer tube at equal arc intervals, and the cover plate is installed at one end of the metal inner tube 2 and the metal outer tube 1 6. An open cavity with one end open and one end closed is formed between the metal inner tube 2, the metal outer tube 1, n stiffening plates and the cover plate 6, and the core materia...

Embodiment 2

[0045] refer to Figure 1 to Figure 5 , a manufacturing process for an energy-dissipative stiffened steel polymer sandwich pipe, the manufacturing process comprising the steps of:

[0046] A. Arrange n pieces of stiffening plates and other arc intervals on the ring of the metal inner tube, n is an integer and greater than or equal to 3;

[0047] B. Sandblasting the metal inner tube and the metal outer tube provided with n stiffening plates;

[0048] C. Place the metal inner tube concentrically in the metal outer tube, and connect the same end of the metal inner tube and the metal outer tube to the cover plate;

[0049] D. The microbead-polyurethane composite material is injected into an open cavity with one end open and one end closed between the metal inner tube, metal outer tube, n stiffening plates and cover plates, and solidified to form a core material;

[0050] E. Cut off the cover plate, and grind the two ends of the energy-stiffening steel-polymer interlayer pipe to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com