Waste heat conversion control method

A conversion equipment and heat transfer technology, applied in heating methods, household heating, household heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

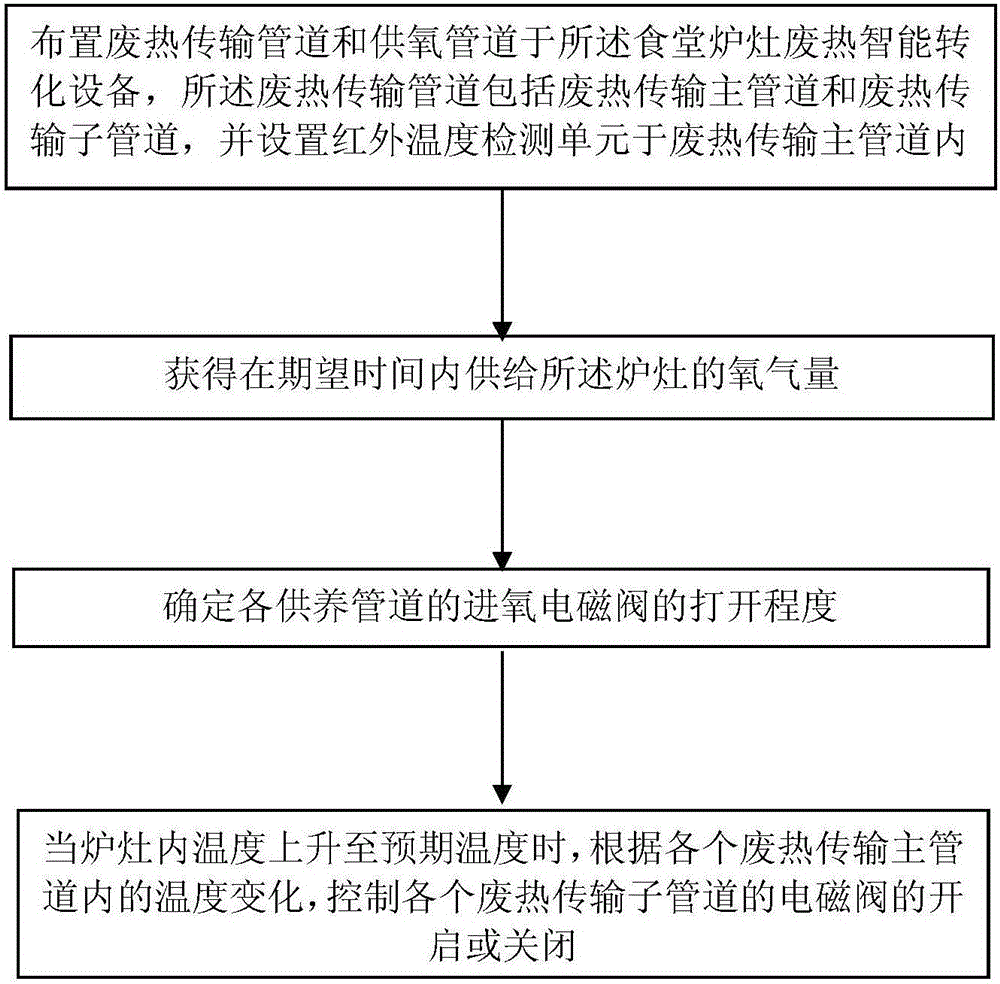

[0049] Such as figure 1 As shown, the intelligent waste heat conversion method of the present invention is used to intelligently control the canteen stove waste heat intelligent conversion equipment, and the method includes the following steps:

[0050] (1) Arranging a waste heat transmission pipeline and an oxygen supply pipeline in the canteen stove waste heat intelligent conversion equipment, the waste heat transmission pipeline includes a waste heat transmission main pipeline and a waste heat transmission sub-pipe, and an infrared temperature detection unit is arranged in the waste heat transmission main pipeline;

[0051] (2) Obtain the amount of oxygen supplied to the stove within a desired time;

[0052] (3) Determine the opening degree of the oxygen inlet electromagnetic valve of each feeding pipeline;

[0053] (4) When the temperature in the stove rises to the expected temperature, the solenoid valves of each waste heat transfer sub-pipe are controlled to be opened o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com