Device and method for measuring concentricity of coupling between turbine and electric generator of turbine set

A technology for a steam turbine unit and a measuring device, which is applied to mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve the problems of inaccurate measurement results, inability to measure concentricity, screw slippage, etc. Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

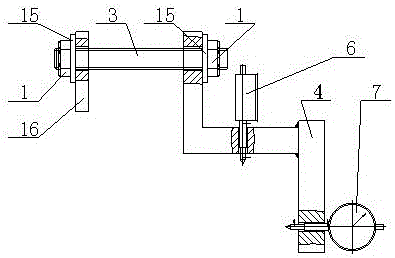

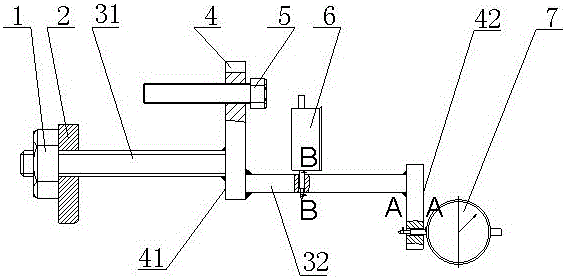

[0032] The device for measuring the concentricity of the shaft coupling between the steam turbine and the generator of the steam turbine unit of the present invention includes two horizontal bars and two vertical bars.

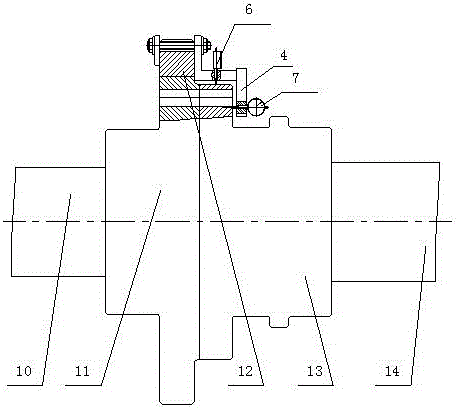

[0033] see now Figure 3-Figure 5 , image 3 It is a schematic structural diagram of a concentricity detection device according to an embodiment of the present invention, Figure 4 for image 3 A-A sectional view in, Figure 5 for image 3 B-B sectional view in . As shown in the figure, one end of the first horizontal bar 31 in the two horizontal bars is provided with a thread, and the thread is equipped with a nut 1, and the other end is solidly welded to the lower part of the first vertical bar 41 in the two vertical bars, and is connected to the first vertical bar 41. The rod is vertical, the first vertical rod is a dial indicator support 4, the top of the first vertical rod is horizontally provided with a threaded hole, and the first jacking screw 5 i...

Embodiment 2

[0037] The method for measuring the concentricity of the steam turbine and the generator coupling of the steam turbine unit of the present invention comprises the following steps:

[0038] a. Clamp the first crossbar 31 with a diameter of 24mm in the groove of the gear of the coupling, and tighten the nut 1 at the threaded end to fasten the backing plate 2;

[0039] b. Tighten the first jacking screw 5 so that the bracket 4 of the dial gauge is tight against the turning gear 12;

[0040] c. Install the first percentile gauge 6 and the second percentile gauge 7;

[0041] d. Rotate the coupling between the steam turbine and the generator to make the coupling rotate, and read the readings of the first and second dial gauges by conventional methods, so that the first dial gauge 6 and the second dial gauge The measuring heads in Subtable 7 respectively measure the shape and position error of the side and end face of the half-coupling on the generator side, that is, the concentrici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com