Gas bubble lifting instrument and use method thereof

A bubble riser, vertical technology, applied in the direction of instruments, measuring devices, measuring fluid pressure, etc., can solve the problems of low standardization of experimental models, influence of interfacial tension method, short time consumption, etc., to ensure consistency and reliability The effects of repeatability, ensuring consistency, and eliminating human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

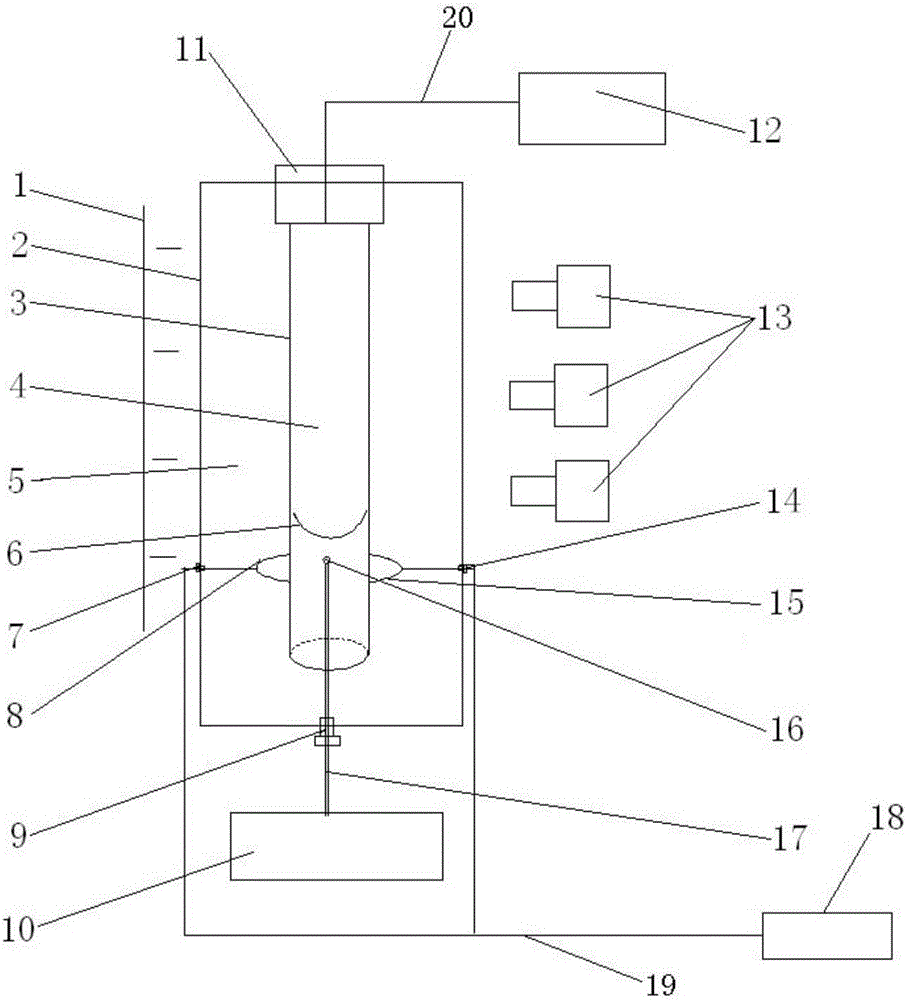

[0034] Such as figure 1 As shown, the present invention provides a foam riser, wherein the foam riser includes: a metal kettle 2, one side of which is provided with a plurality of cameras 13 along the vertical direction, and the other side is provided with a plurality of said The light source body 1 relative to the camera 13; the glass cylinder 3, which is located in the metal kettle 2, the upper end of the glass cylinder 3 is fixed on the top wall of the metal kettle 2 and is connected to the first pump 12, and the glass cylinder 3 The lower end of the cylinder 3 is an opening, and the glass cylinder 3 communicates with the metal kettle 2 through the opening; the gas injection needle tube 17, whose needle tail end is connected with the second pump 10, and the needle end passes through the metal kettle The bottom wall of 2 extends into the glass cylinder 3; two electromagnetic coils are connected to the controller 18, and the two electromagnetic coils are located in the metal ...

Embodiment approach 2

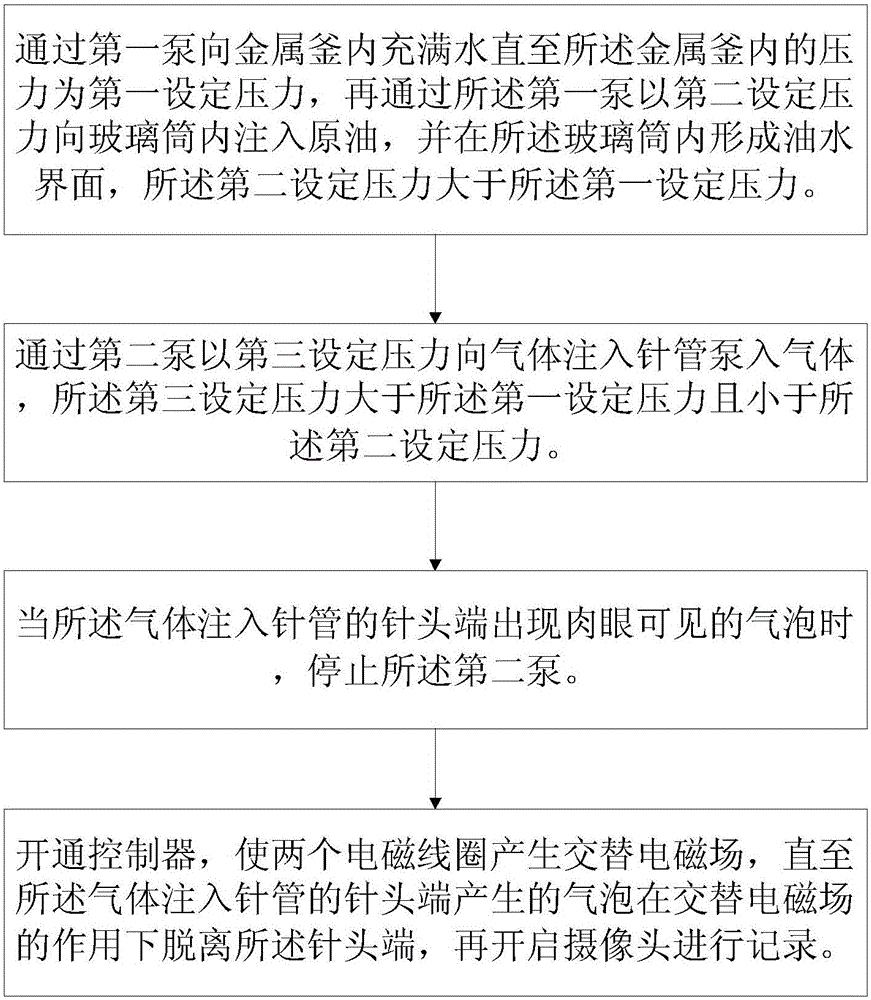

[0041] The present invention provides a method for using the foam riser described in Embodiment 1. The structure, working principle and beneficial effects of the foam riser in this embodiment are the same as those in Embodiment 1, and will not be repeated here. Such as figure 2 Shown, the using method of described bubble riser comprises the steps:

[0042] Step a: fill the metal kettle 2 with water 5 through the first pump 12 until the pressure in the metal kettle 2 reaches the first set pressure, and then fill the glass cylinder 3 with the second set pressure through the first pump 12 Inject crude oil 4, and form an oil-water interface 6 in the glass cylinder 3, and the second set pressure is greater than the first set pressure;

[0043] Step b: using the second pump 10 to pump gas into the gas injection needle 17 at a third set pressure, the third set pressure being greater than the first set pressure and lower than the second set pressure;

[0044] Step c: Turn on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com