Detachable bolt anchoring characteristic test bench

A characteristic test and dismantling technology, applied in the direction of strength characteristics, using stable tension/pressure test material strength, measuring device, etc., can solve the problems of excessive material waste, complicated experimental procedures, and prolonged experimental preparation time, and reduce The effect of test cost, improving test efficiency and shortening test preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

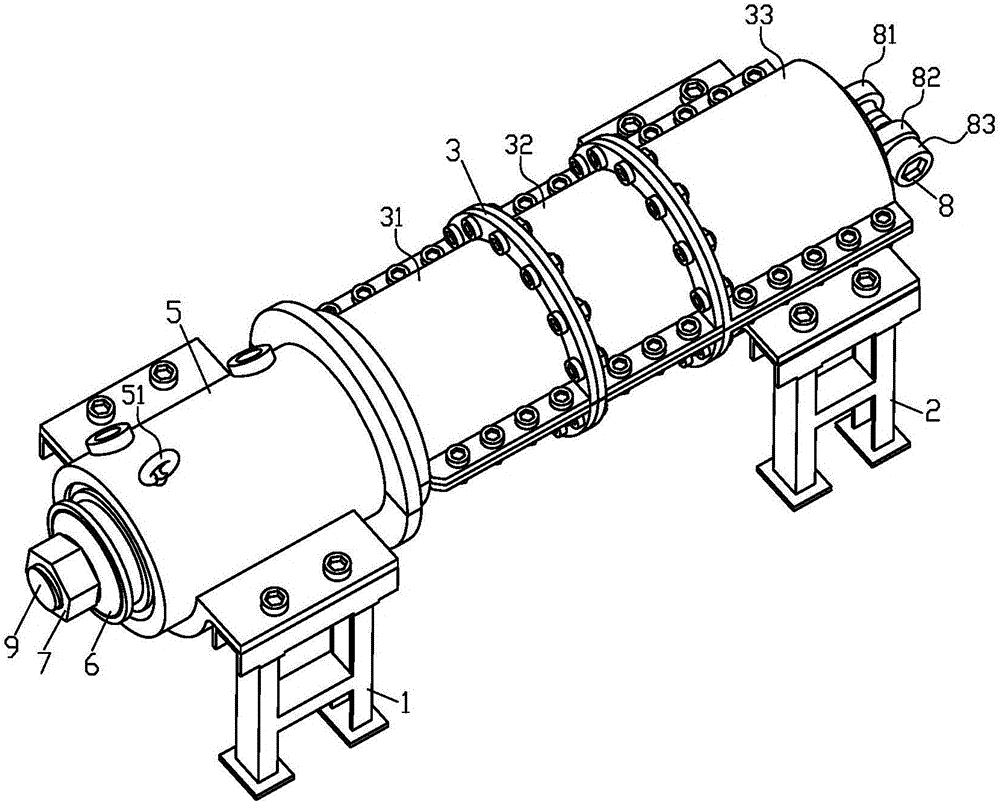

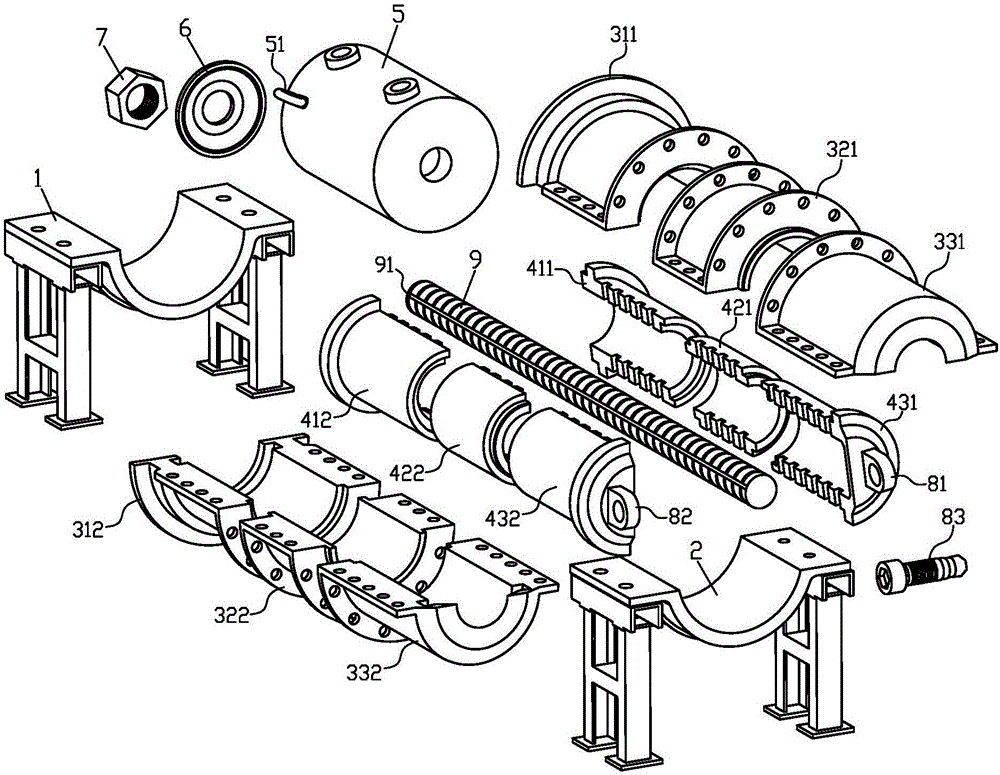

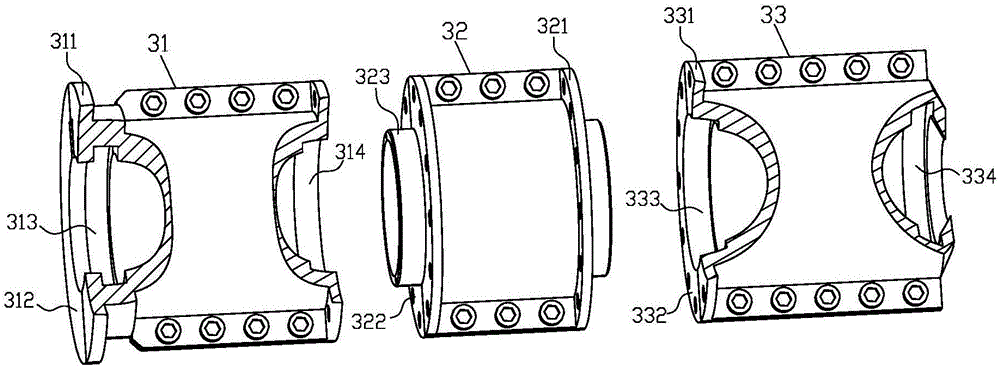

[0026] Such as figure 1 , figure 2 , Figure 5 and Figure 6 As shown, a detachable rock bolt anchoring characteristic test bench includes a front bracket 1, a rear bracket 2, a detachable fixer 3, a simulated anchor 4, an anchor puller 5, a tray 6, a nut 7, and an anchor Separator 8 and anchor rod 9. Wherein, the anchor rod pullout meter 5 is installed on the front bracket 1, and is used to apply an axial pulling force to the anchor rod 9 in the test, so as to measure the anchoring force, pull-out force and the bearing force of the anchor rod 9. The relationship between the pulling force and the displacement; the rear end of the detachable fixer 3 is installed on the rear bracket 2 for fixing and installing the simulat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap