Apparatus for preparing and testing soil-rock interface sample for on-site direct shear test

A technology of sample preparation and test equipment, which is applied in the preparation of test samples, measurement equipment, and the use of stable shear force to test the strength of materials, etc., can solve the problems of increased risk, difficult labor, and heavy workload. Achieve the effects of reducing eccentricity, convenient installation and disassembly, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

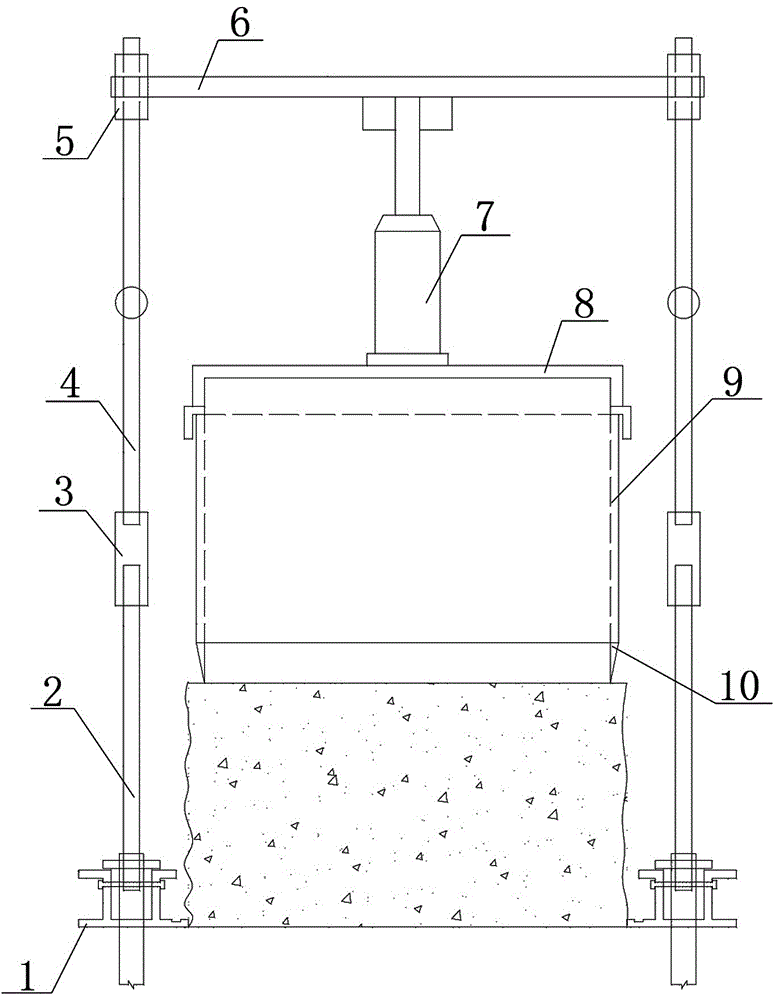

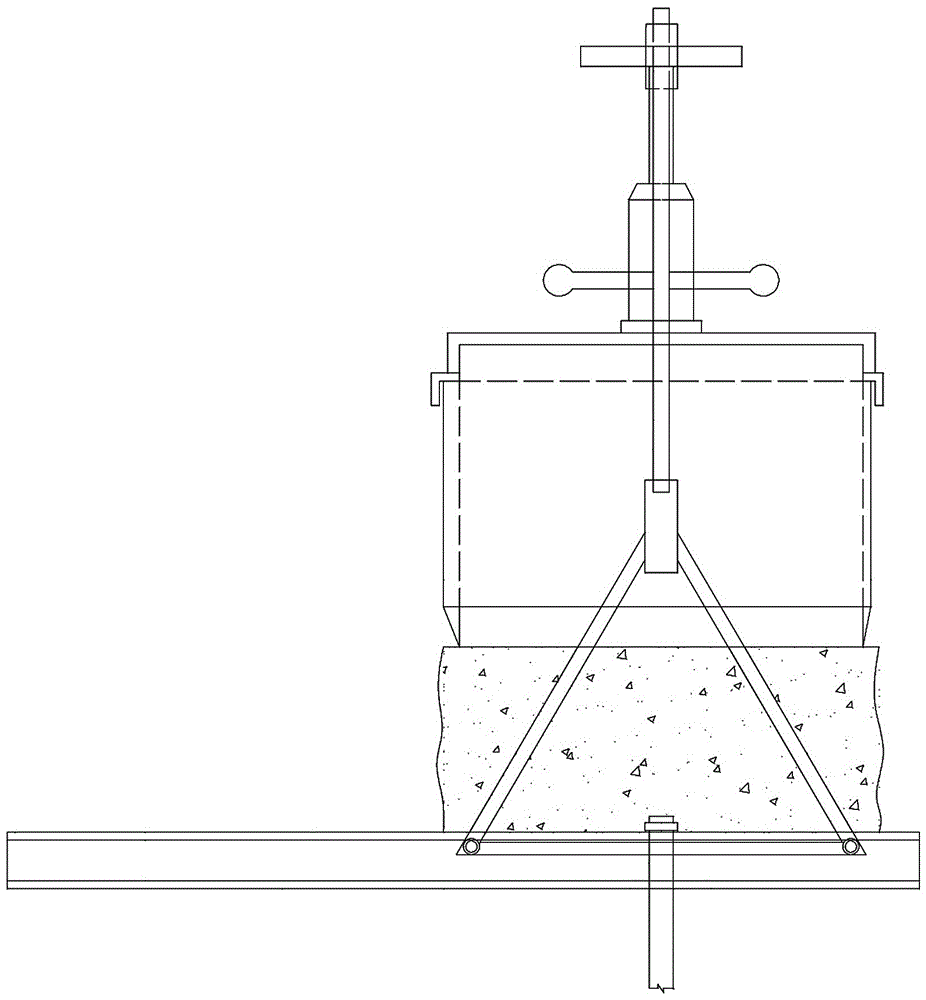

[0036] Embodiment 1: soil-rock interface field direct shear test sample preparation and test device, it comprises two mutually parallel rail frames 1, and rail frame 1 is provided with tripod 2, and tripod 2 top is provided with sleeve 3, and sleeve 3 The upper end is connected with a telescopic rod 4, and the telescopic rod 4 is connected with the top plate 6 through a sleeve 5, and a hydraulic jack 7 is vertically arranged below the top plate 6, and the hydraulic jack 7 is connected with the force transmission frame 8, and the lower end of the force transmission frame 8 is connected with the shear box 9 Connected, the shear box 9 is a square frame surrounded by sides around.

[0037] A detachable soil cutter 10 is installed at the lower end of the shearing box 9 .

[0038] A handle 19 is provided on the telescopic rod 4 .

[0039] When preparing soil samples, the following steps are included:

[0040] 1) Manually excavate a ring-shaped soil pit at the selected test site. T...

Embodiment 2

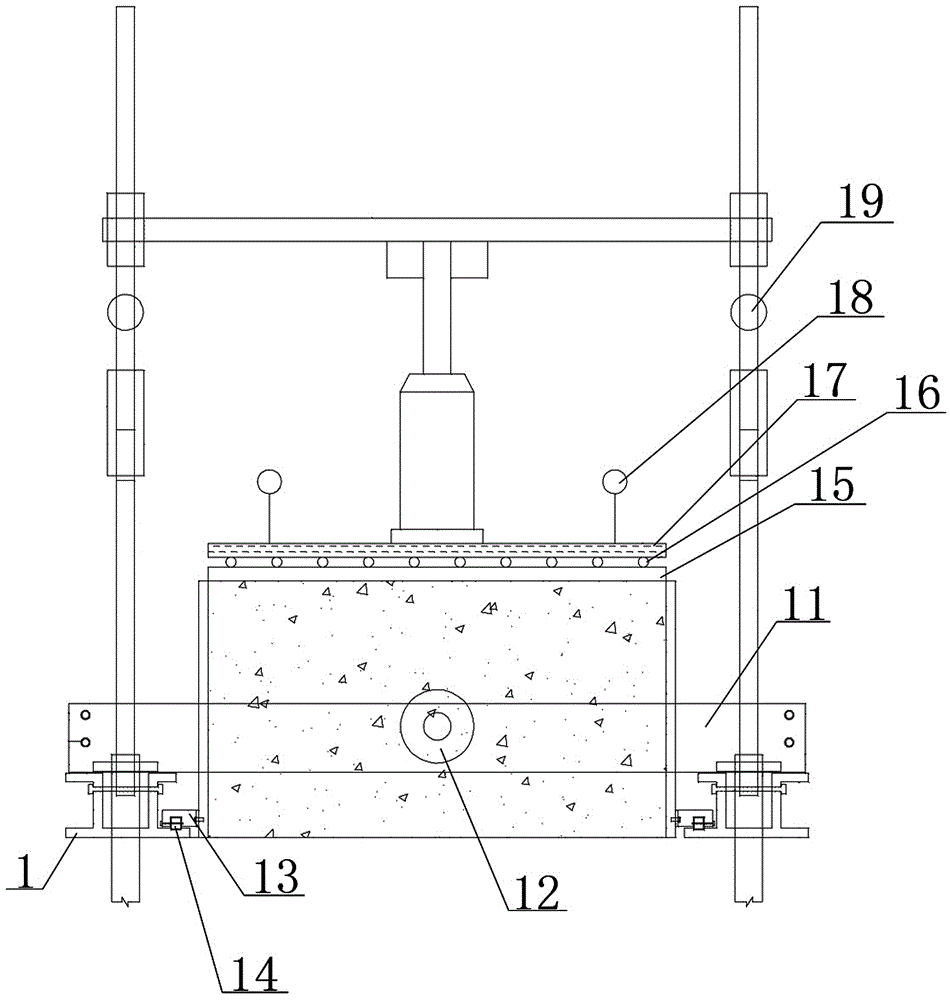

[0044] Embodiment 2: A horizontal loading frame 11 is erected on two mutually parallel guide rail frames 1 , and a horizontal jack 12 is provided perpendicular to the horizontal loading frame 11 and on a horizontal plane.

[0045] Both sides of shearing box 9 are provided with rolling guide box 13, and the wheels 14 on the rolling guide box are arranged in the roller track on the guide rail frame 1.

[0046] The shearing box 9 is provided with a lower pressure plate 15, an upper pressure plate 17 is arranged above the lower pressure plate 15, and a roller row 16 is arranged between the lower pressure plate 15 and the lower pressure plate 17.

[0047] On the force plate 17, a vertical displacement measuring device magnetic base and a dial gauge 18 are placed.

[0048] A method for loading a direct shear test comprising the following steps:

[0049] 1) After the sample preparation is completed, remove the soil cutter on the shear box, depressurize the jack and return it, first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com