Method and system for measuring saturation current of element

A saturation current and component technology, applied in the field of failure analysis of semiconductor devices, can solve the problems of misjudgment of abnormal analysis results, poor accuracy of saturation current value, failure analysis can not continue, etc., to achieve the effect of good data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. Of course, the present invention can also have other embodiments besides these detailed descriptions.

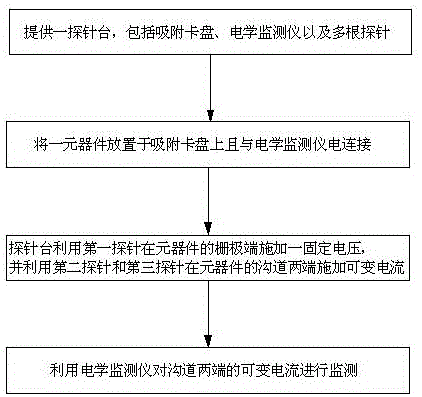

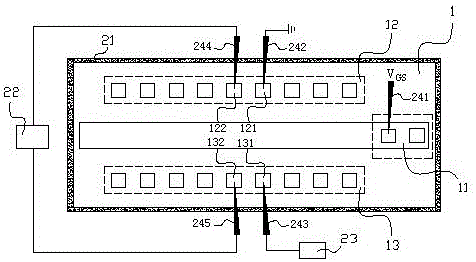

[0033] The method for measuring the saturation current of a component of the present invention applies a voltage identical to that of the component to the gate (Gate) of the component to convert the voltage between the source (Source) and the drain (Drain) of the component to The channel is fully turned on; then a variable current is applied across the channel, and the voltage difference across the channel is detected using a nanoprobe station (Nanoprober); when the voltage difference across the channel reaches the drain operating voltage, read At this time, the current value applied to the channel is the saturation current value of the component.

[0034] The measurement method and measurement system of the present invention w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com