RF PCB testing device based on RF probe and rotary joint base

A technology of rotating joints and testing devices, applied in RF circuit testing, electronic circuit testing and other directions, can solve the problems of long assembly time, waste of manpower and material resources, etc., to overcome the long time, reduce the waste of manpower and material resources, and improve the test efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

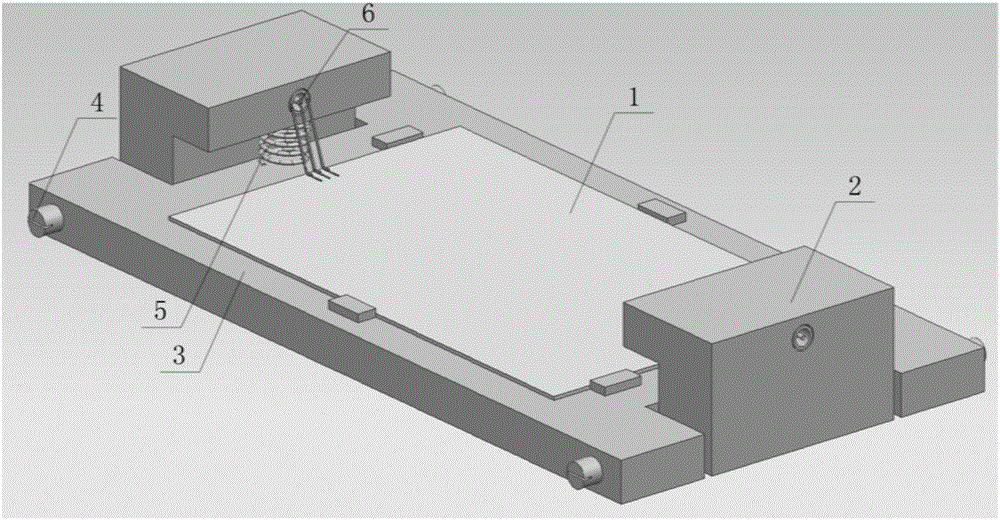

[0009] The schematic diagram of the testing device of the present invention is as figure 1 shown. The base 2 on which the radio frequency probe is installed is assembled on both ends of the base 3 on which the printed board is installed through the rotating joint 4 and the elastic device 5, so that the base 2 has the functions of rotatable lifting and automatic compression at the same time. Four columns can be designed on the printed board base 3 to provide positioning for the installation of the printed board, avoiding manual adjustment of the position of the printed board; the radio frequency probe 6 is installed on the base 2 and has elasticity, so that the probe and the printed board The RF port of the board can be in good contact. During the test, it is only necessary to lift the base 2 with elastic radio frequency probes installed at both ends, and place the radio frequency printed board 1 to be tested in the middle of the base 3 on which the printed board is installed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com