Single-shaft high-precision servo control system adjustment and control device

A technology of servo control system and commissioning device, applied in general control system, control/regulation system, digital control, etc., can solve problems such as no instructions or reports found, no data collected, etc., to achieve correctness and robustness of verification sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

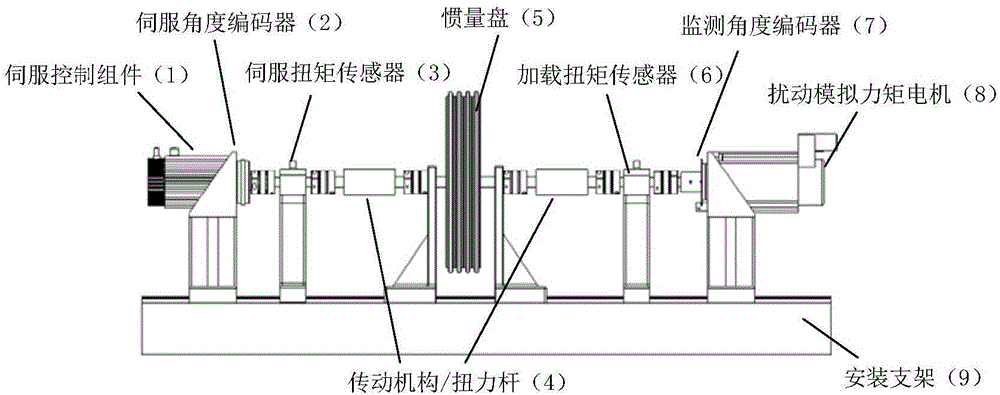

[0016] refer to figure 1 It is a schematic diagram of the single-axis high-precision servo control system commissioning device scheme. Through the present invention, the adaptive adjustment of the transmission gap, transmission stiffness, load eccentricity, disturbance resistance torque, etc. of the servo mechanism can be conveniently realized, so that the single-axis high-precision The servo control system is used for control scheme design and effect evaluation.

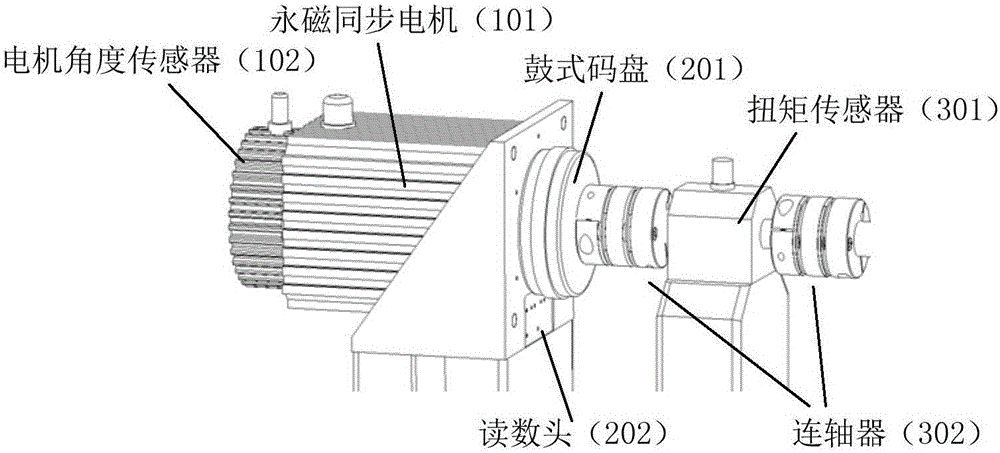

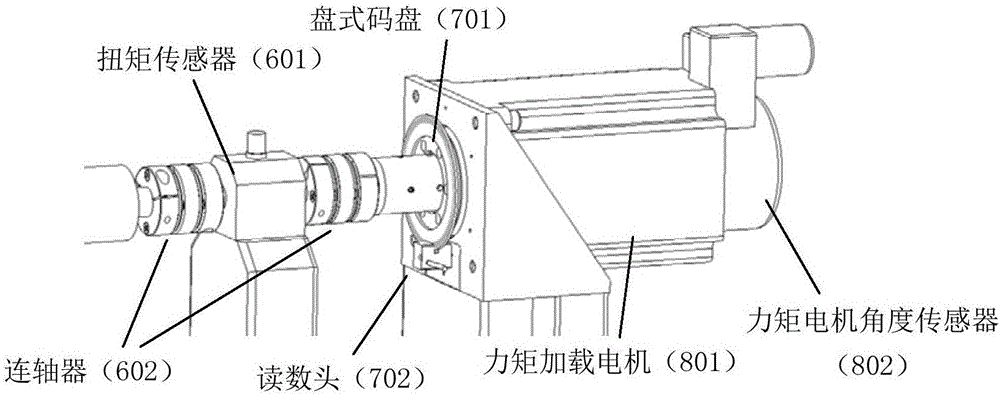

[0017] The test device provided by the present invention includes: servo control assembly 1, servo angle encoder 2, servo torque sensor 3, transmission mechanism / torque bar 4, inertia disk 5, loading torque sensor 6, monitoring angle encoder 7, disturbance simulation torque The motor 8 and the mounting bracket 9 are nine parts.

[0018] The mounting bracket 9 provides various installation mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com