Power transformer capable of automatically adjusting oil level

A power transformer and self-regulating technology, applied in transformer/inductor cooling, non-electric variable control, control/regulation systems, etc., can solve the problems of small effective area, inability to cool the transformer, and heat is not easily dissipated quickly, and achieve uniform heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

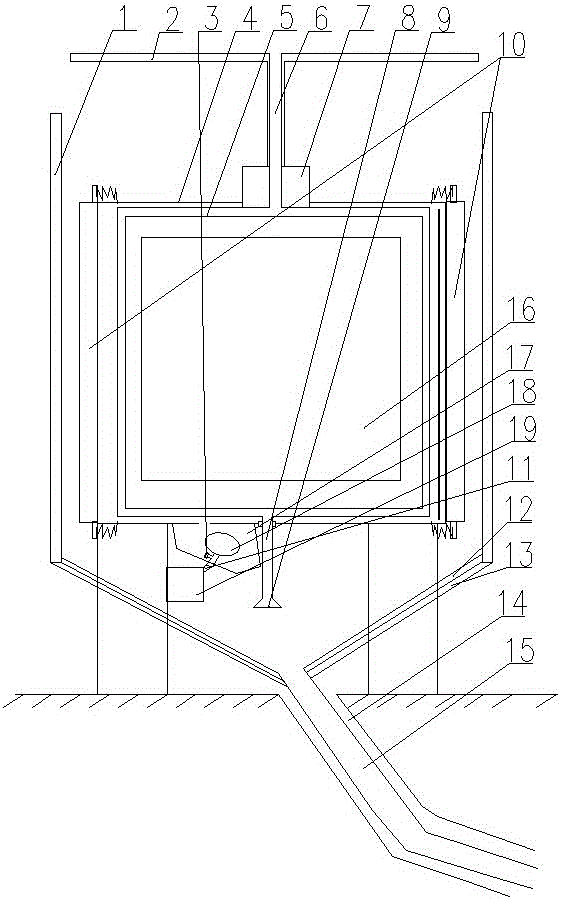

[0029] Such as figure 1 As shown, an oil level self-regulating power transformer includes a box body 4 and an iron core 16 located in the box body. The side of the box body 4 is provided with a cooling plate 10 through an elastic mechanism, and the side of the box body is provided with an annular sleeve. cylinder 1, the annular sleeve is provided with a deflector 12, the outside of the deflector 12 is provided with a radiation-resistant and heat-insulating paint layer 13, and the fuel tank is provided with an auxiliary fuel tank 17 connected thereto, and the auxiliary fuel tank is provided with There is an air bag 18, and the air bag is connected with the compressor 19 under the casing, and the compressor is connected with a programmable controller, and the programmable controller is connected with an oil level sensor in the oil tank, when the oil level is lower than the set value ( Low value), the programmable controller controls the compressor to inflate the air bag, the liq...

Embodiment 2

[0044] As a further improvement of the first embodiment, the conduit adopts a corrugated tube, which is easy to bend.

Embodiment 3

[0046] As a further improvement of Embodiment 2, the height of the annular sleeve is 1.5 times the height of the box body. If the height of the annular sleeve is low, it is easy to irradiate the transformer. If the annular sleeve is high, the chimney effect is not obvious, and the absorption of underground air force is small. The diameter of the annular sleeve is 1.2 times the width of the box body, which can form the largest rise of hot gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com