Plasma generator applied to auxiliary ignition in shock tube

A technology of plasma and shock tube, applied in the field of plasma generation device, to achieve the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

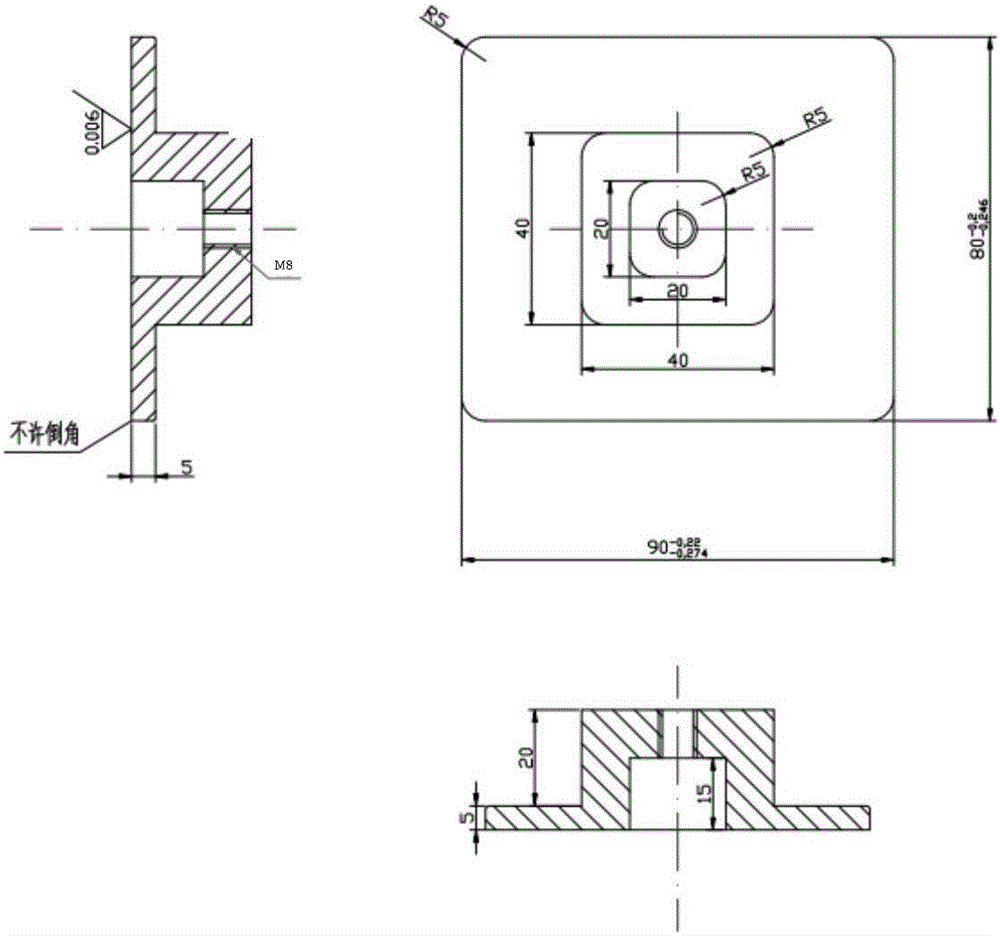

[0028] Such as figure 1 As shown, the discharge unit is composed of a base (3), a pressure block (4), a plug (5) and a copper bolt (6). There is a gap in the fit between the base (3) and the plug (5), and the purpose is to reserve a copper mesh to pass through. The pressure block (4) and the copper bolt (6) are connected by M8 threads. The copper mesh is connected to the copper bolt in the cavity of the pressure block (4), and the copper bolt is welded with wires to connect to the external plasma power supply. Therefore, when the plasma power supply is turned on, the copper mesh in the discharge unit will pass through The dielectric layer and the shock tube body discharge.

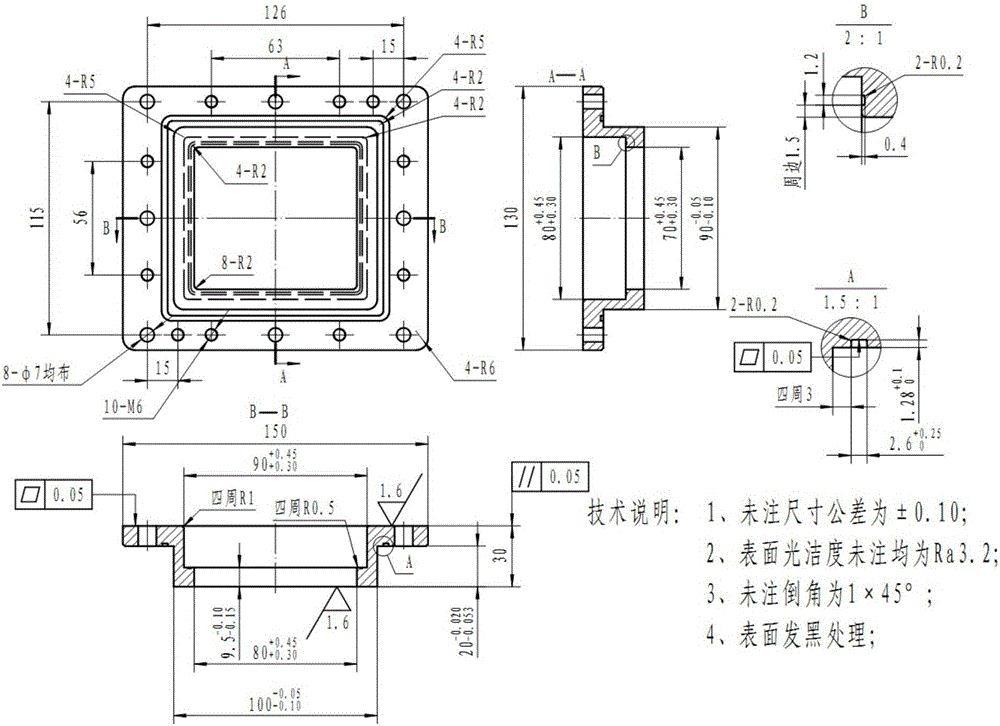

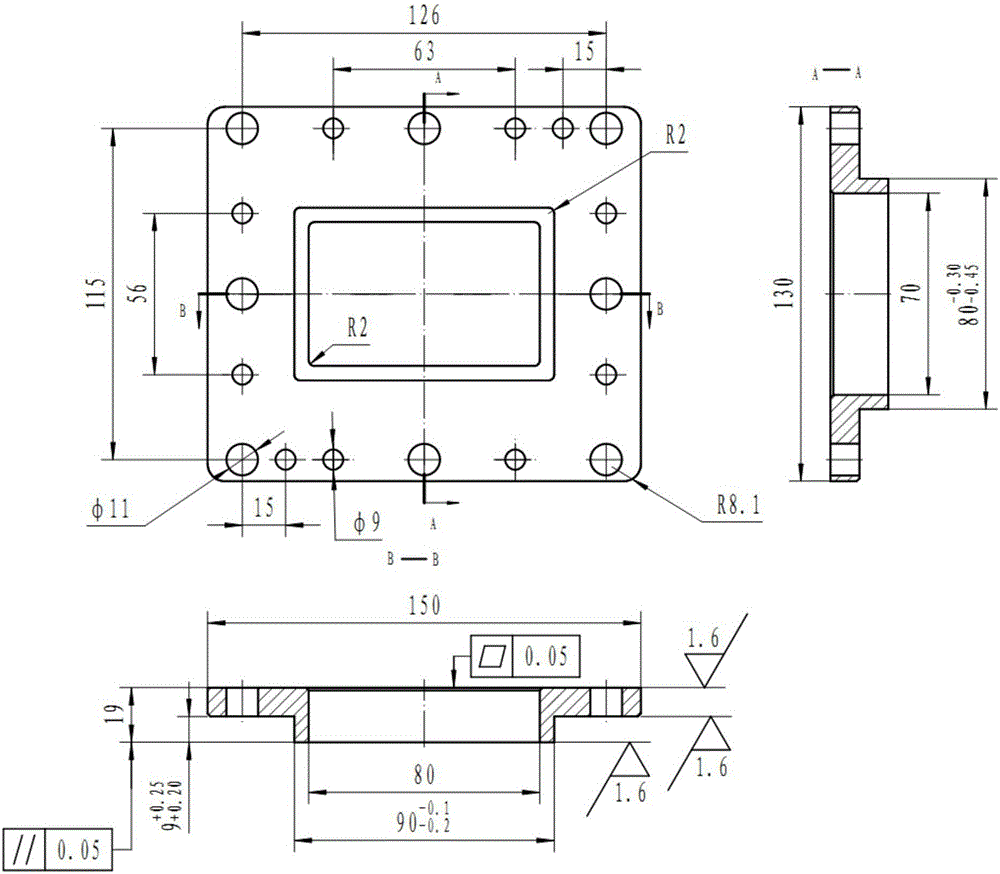

[0029] Figure 2(a) shows the schematic structure of the plug. The material of the plug is polytetrafluoroethylene, and the plug is designed with notches for embedding the copper mesh. Since the discharge will have a corrosive effect on the PTFE insulation layer, the plug can be replaced after a period of u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com