System and method for organic solvent purification

一种有机溶剂、渗透气化的技术,应用在化学仪器和方法、有机化学、分离方法等方向,能够解决离子交换树脂大量工夫、离子交换效率小等问题,达到热回收效率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

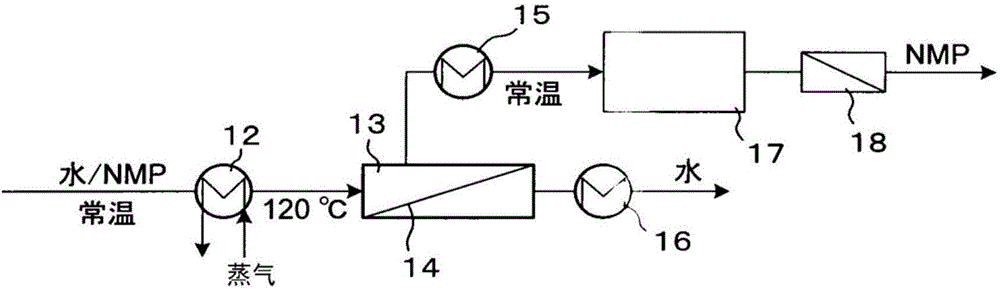

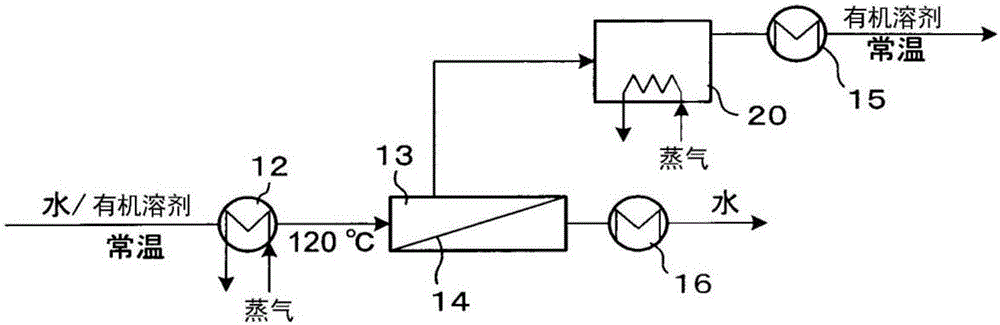

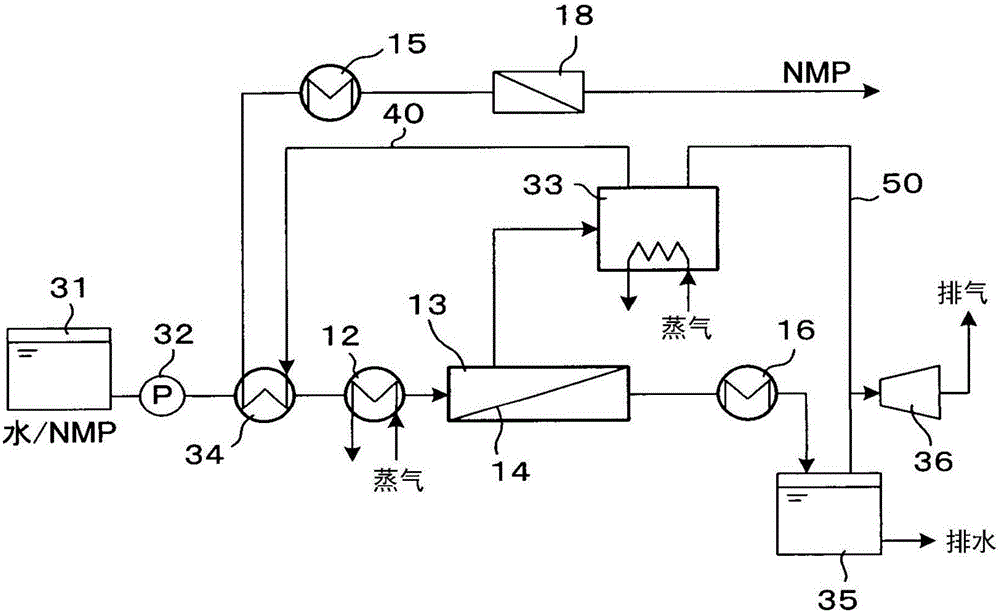

[0027] Next, preferred embodiments of the present invention will be described with reference to the drawings. image 3 The basic scheme of the organic solvent purification system based on this invention is shown as the organic solvent purification system which is one of the embodiment of this invention. This organic solvent purification system is a system for separating and purifying an organic solvent from a mixed solution of an organic solvent and water, for example, it is for recovering NMP (N-methyl-2 -pyrrolidone) and water mixture, and the system used to separate and purify NMP from the mixture. Hereinafter, the case of using NMP as an organic solvent will be described, but the applicable organic solvent of the present invention is not limited to NMP, generally speaking, for the boiling point at atmospheric pressure (0.1013Mpa) is higher than the boiling point of water (100 ° C), preferably Organic solvents whose boiling point under atmospheric pressure is 120° C. or hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com