Negative electrode for all-solid battery and all-solid battery including same

An all-solid-state battery and negative electrode technology, applied in the direction of battery electrodes, batteries, negative electrodes, etc., can solve problems such as insufficiency, and achieve the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084]The preparation method of the negative electrode active material layer is not particularly limited, and the negative electrode active material can be prepared by mixing the carbonaceous material and the solid electrolyte material, and the conductive aid and / or binder added as required, and then press-molded Floor. In addition, carbonaceous materials, solid electrolyte materials, and conductive additives and / or binders may also be mixed in a specific solvent to form a slurry, which is then coated, dried, and then pressed. molding to prepare a negative electrode active material layer.

[0085] The negative electrode active material layer usually has a current collector. As the negative electrode current collector, for example, SUS, copper, nickel or carbon can be used, among which Cu or SUS is preferable.

[0086] "Positive electrode active material layer"

[0087] The positive electrode active material layer contains a positive electrode active material and a solid ele...

Embodiment

[0103] Hereinafter, the present invention will be specifically described by way of examples, but the scope of the present invention is not limited to these examples.

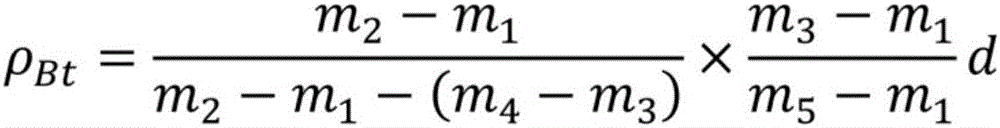

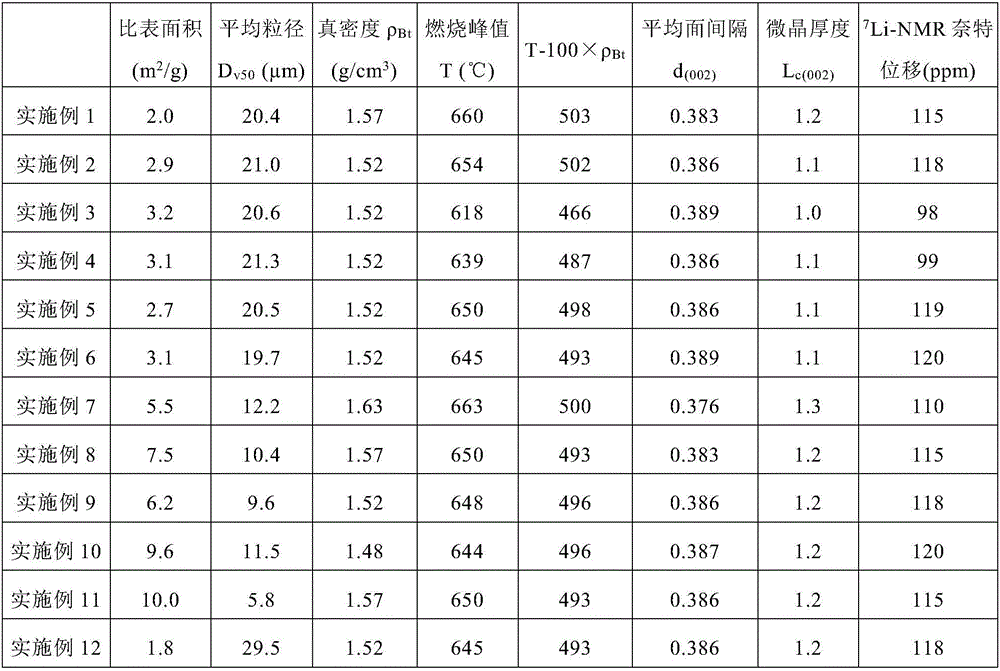

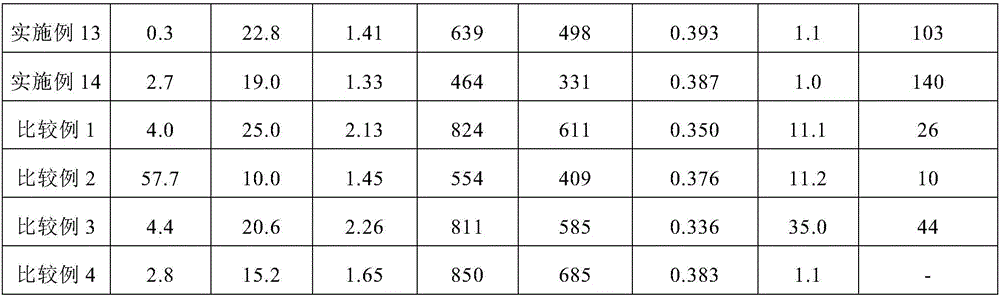

[0104] In addition, the following describes the physical property values of the carbonaceous material for non-aqueous electrolyte secondary batteries of the present invention ("The average interplanar distance d of the (002) plane measured by X-ray diffraction method (002) and the crystallite thickness L in the direction of the c-axis c(002) ", "Specific Surface Area", "True Density Calculated According to Butanol Method", "Average Particle Size Measured According to Laser Diffraction Method", " 7 Li-NMR analysis" and "differential thermal analysis measurement") measurement methods, including Examples, and the physical property values described in this specification are all values calculated based on the following methods.

[0105] "The average interplanar spacing d of (002) planes in carbonaceous materia...

preparation example 1

[0130] Put 70kg of petroleum pitch and 30kg of naphthalene with a softening point of 205°C, an H / C atomic ratio of 0.65, and quinoline insolubles of 0.4% into a pressure-resistant container with a stirring blade and an outlet nozzle and an internal volume of 300 liters. Heat to melt and mix for 1 to 2 hours. Then, the heated, melted and mixed petroleum pitch was cooled to about 100°C, the inside of the pressure vessel was pressurized with nitrogen, and the content was extruded through the outlet nozzle to obtain a rope-shaped molded body with a diameter of about 500 μm. Next, crush the rope-shaped molded body so that the ratio (L / D) of its diameter (D) to length (L) is about 1.5 to 2.0, and add the obtained crushed product to 93°C and dissolve Stir, disperse and cool in an aqueous solution of 0.53 mass percent polyvinyl alcohol (saponification degree: 88%) to obtain spherical asphalt molded body slurry. After most of the water was removed by filtration, naphthalene in the asp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com