A multi-point long-pin connector that is convenient to disassemble and assemble and disassemble method thereof

A technology that facilitates disassembly and assembly of connectors. It is applied in the direction of connection, coupling device, assembly/disassembly of contact pieces, etc. It can solve the problems of small operating space, burnt circuit, damage, etc., achieve low-cost equipment assembly, and avoid pin insertion Effect of damage, easy lifting and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

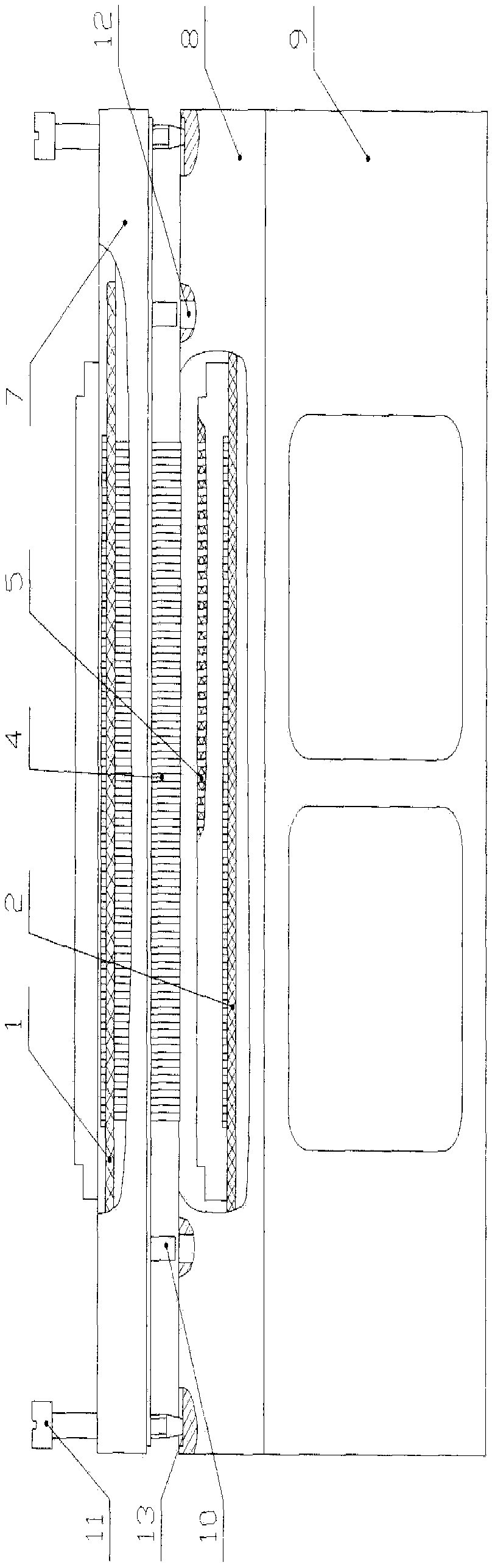

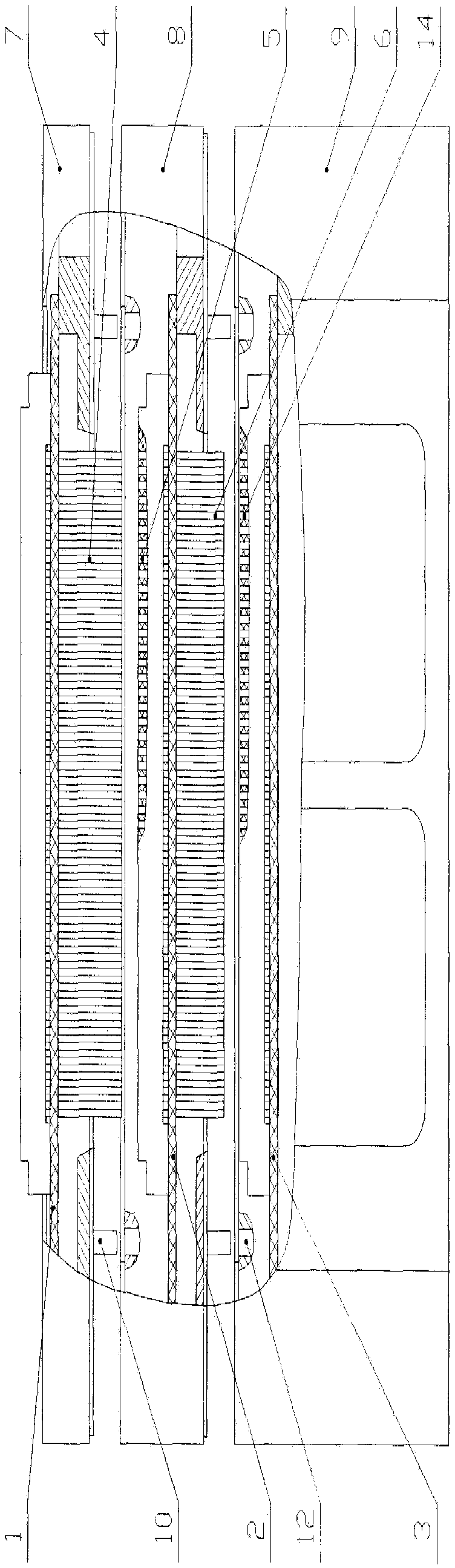

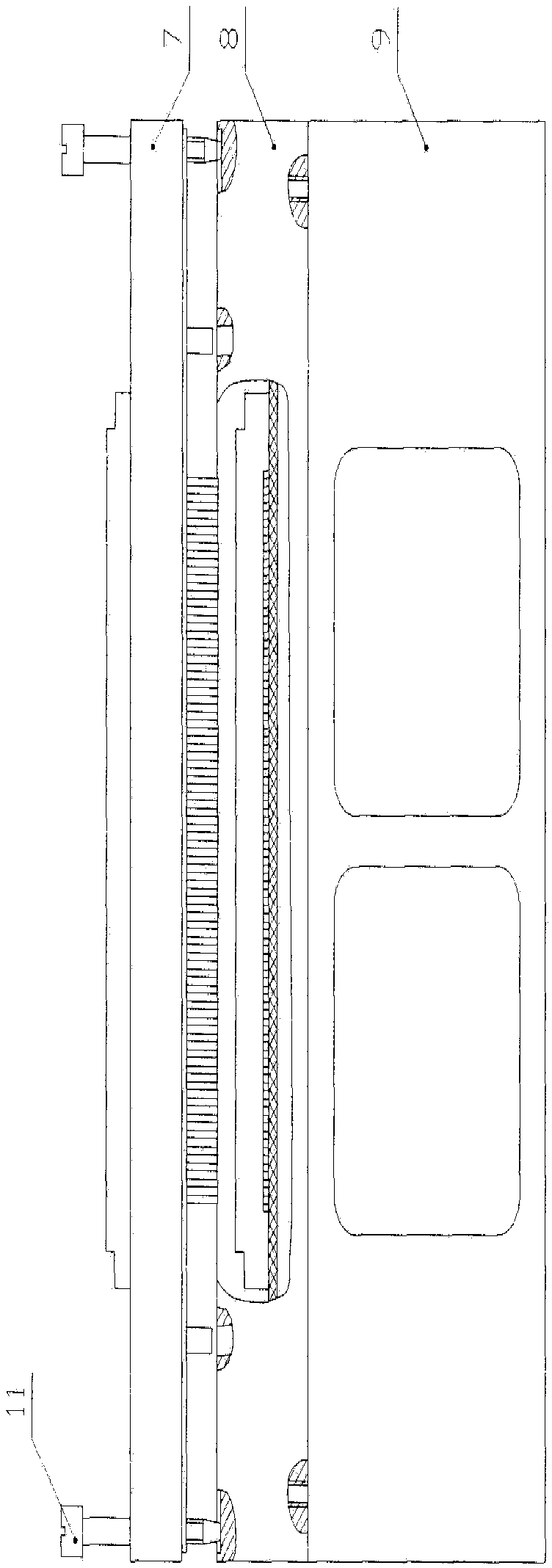

[0029] Such as figure 1 Shown is the structural representation of multi-point long-pin connector of the present invention, as figure 2 Shown is the schematic diagram of the structural decomposition of the multi-point long-pin connector of the present invention. In this example, three connector units are included. The connector unit includes a printed board, a connector and a housing, and the connector is composed of a jack and pins. Depend on figure 2 It can be seen that the pin 4 installed under the printed board 1 in the first layer of connector unit cooperates with the jack 5 installed above the printed board 2 in the second layer of connector unit, and the second layer of connector unit is installed on the printed board 1. The pins 6 below the printed board 2 cooperate with the jacks 14 installed above the printed board 3 in the third-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com