Novel organic waste gas purification tower

A technology of organic waste gas and purification tower, which is applied in the direction of gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problems of increasing the complexity of the purification device system, increasing investment and operating costs, and uneconomical recovery methods, etc. Produces secondary pollution, convenient and fast use and maintenance, and low concentration range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

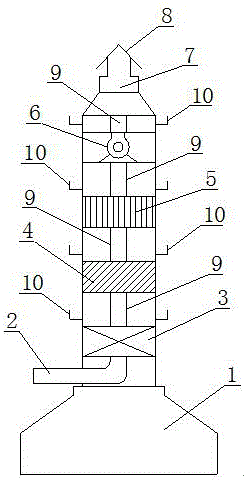

[0013] Specific embodiment one, please refer to figure 1 , a new type of organic waste gas purification tower, including a base 1, a pretreatment device 3, a fan 6, a chimney 7 and a pipeline 9, the purification tower is fixed on the base 1, and the bottom of the base 1 is provided with an organic waste gas inlet pipe 2. The organic waste gas inlet pipe 2 is connected to the bottom of the pretreatment device 3, and the top of the pretreatment device 3 is connected to the bottom of the waste gas purification device 4 through a pipeline 9, and the top of the waste gas purification device 4 It communicates with the bottom of the post-processing equipment 5 through a pipeline 9, the top of the post-processing equipment 5 communicates with the bottom of the blower 6 through a pipeline 9, and the top of the blower 6 communicates with the bottom of the chimney 7 through The pipes 9 are connected, the top of the chimney 7 is provided with a rainproof cover 8, the surroundings of the p...

specific Embodiment 2

[0014] Specific embodiment two, please refer to figure 1 , see figure 1 , a new type of organic waste gas purification tower, including a base 1, a pretreatment device 3, a fan 6, a chimney 7 and a pipeline 9, the purification tower is fixed on the base 1, and the bottom of the base 1 is provided with an organic waste gas inlet pipe 2. The organic waste gas inlet pipe 2 is connected to the bottom of the pretreatment device 3, and the top of the pretreatment device 3 is connected to the bottom of the waste gas purification device 4 through a pipeline 9, and the top of the waste gas purification device 4 It communicates with the bottom of the post-processing equipment 5 through a pipeline 9, the top of the post-processing equipment 5 communicates with the bottom of the blower 6 through a pipeline 9, and the top of the blower 6 communicates with the bottom of the chimney 7 through The pipes 9 are connected, the top of the chimney 7 is provided with a rainproof cover 8, the surro...

specific Embodiment 3

[0015] Specific embodiment three, please refer to figure 1 , see figure 1 , a new type of organic waste gas purification tower, including a base 1, a pretreatment device 3, a fan 6, a chimney 7 and a pipeline 9, the purification tower is fixed on the base 1, and the bottom of the base 1 is provided with an organic waste gas inlet pipe 2. The organic waste gas inlet pipe 2 is connected to the bottom of the pretreatment device 3, and the top of the pretreatment device 3 is connected to the bottom of the waste gas purification device 4 through a pipeline 9, and the top of the waste gas purification device 4 It communicates with the bottom of the post-processing equipment 5 through a pipeline 9, the top of the post-processing equipment 5 communicates with the bottom of the blower 6 through a pipeline 9, and the top of the blower 6 communicates with the bottom of the chimney 7 through The pipes 9 are connected, the top of the chimney 7 is provided with a rainproof cover 8, the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com