Circuit comprehensive commissioning and welding platform device for easy disassembly and assembly of electric soldering iron welding head

A technology of circuit synthesis and soldering platform, which is applied in the direction of electronic circuit testing, soldering iron, tin feeding device, etc., can solve problems such as low soldering efficiency, non-concentrated functions, and poor safety, so as to reduce signal interference, reduce unreliability, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

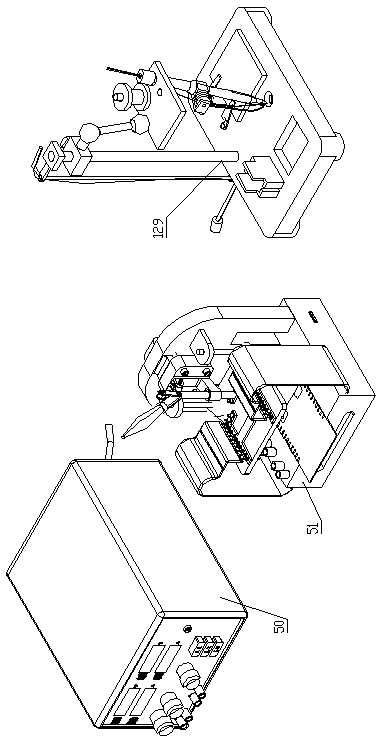

[0052] like Figure 1-Figure 11 As shown, the circuit comprehensive debugging and welding platform device of the easy-to-disassemble electric soldering iron welding head of the present invention includes a control host 50 , a circuit board test fixture 51 and a circuit board fast soldering device 129 .

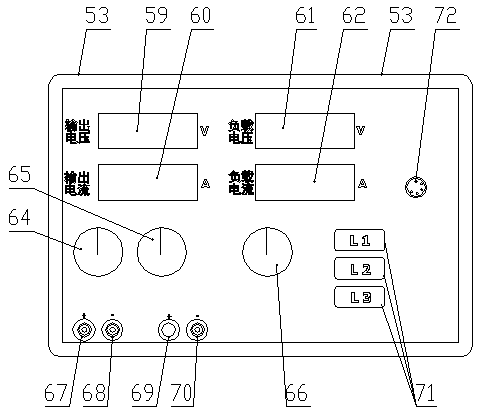

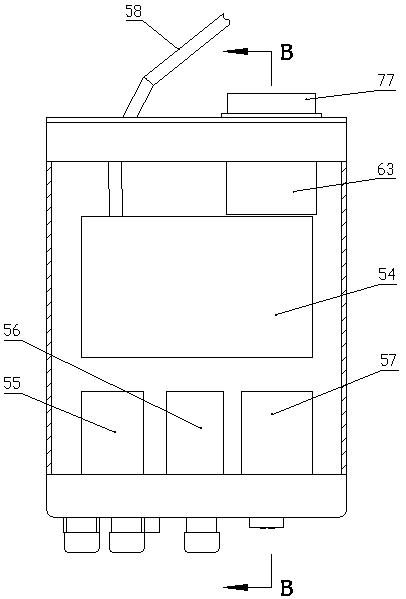

[0053] The control host 50 includes a box body 53 in the shape of a cuboid. The box body 53 is provided with a power drive module 54, a switching power supply control module 55, a load control module 56 and a welder constant temperature heating module 57. The rear side of the power drive module 54 is connected to a Stretch out the 220V power line 58 of box body 53 behind, the inner rear part of box body 53 is provided with the radiator 63 that contacts with power drive module 54; Load control module 56 is connected with power drive module 54, and load control module 56 is connected with switch respectively. The power supply control module 55 is connected with the welder consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com