Clamping and laser cutting device of power engineering elbow

A technology of electric power engineering and laser cutting, which is applied in laser welding equipment, manufacturing tools, metal processing, etc., can solve problems such as difficult control of power tools, unconscious movement, and low efficiency of guide wheels, so as to reduce maintenance costs and improve production efficiency , Guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

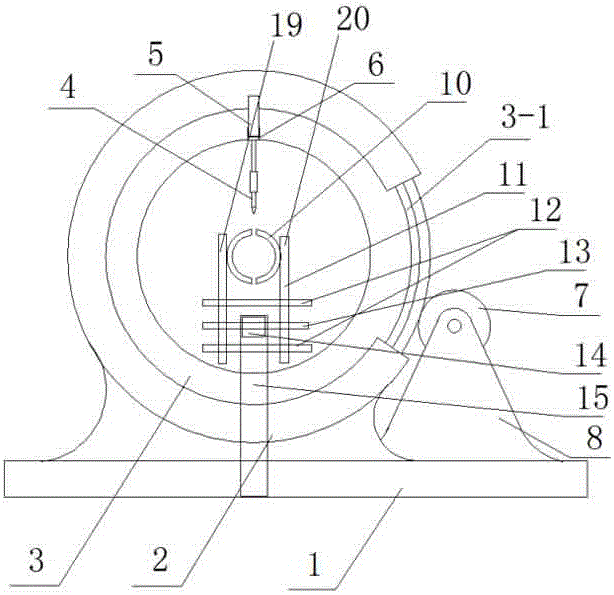

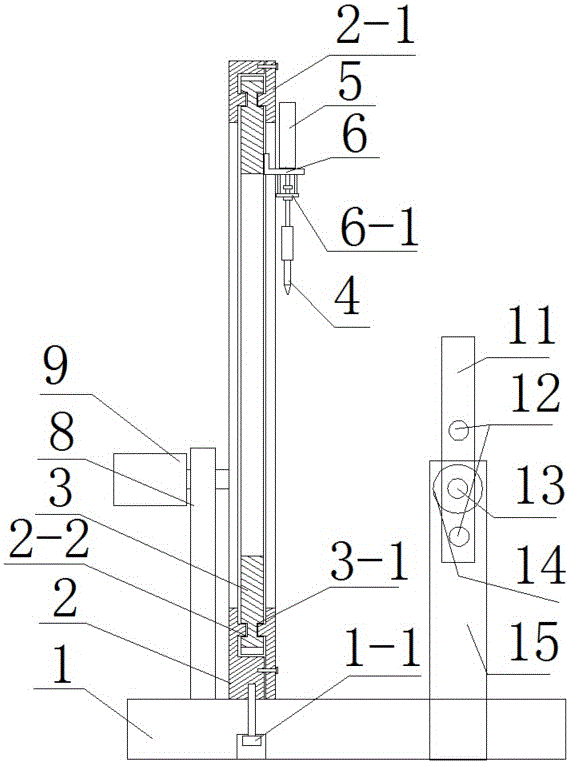

[0024] Such as figure 1 , 2 As shown, the electrical engineering elbow clamping laser cutting device of the present invention includes a base 1, a housing, a ring gear 3, a laser cutting head 4, a telescoping mechanism 5 and a workpiece clamping mechanism, and the bottom of the housing can pass through the connecting piece 1- 1 is connected to the base 1, and for the convenience of installation and maintenance, the housing can be set as a two-body structure in which the body 2 is connected to one side cover plate 2-1. The side wall of the body 2 and the central part of the cover plate 2-1 are provided with an axial through hole for the pipe to be cut to pass through. The ring gear 3 is movably connected with the housing through a sliding connection mechanism to ensure that the ring gear 3 can rotate freely. The telescopic mechanism 5 is fixedly connected to the position of the ring gear 3 close to the axis through the bracket 6, and the laser cutting head 4 is connected to t...

Embodiment 2

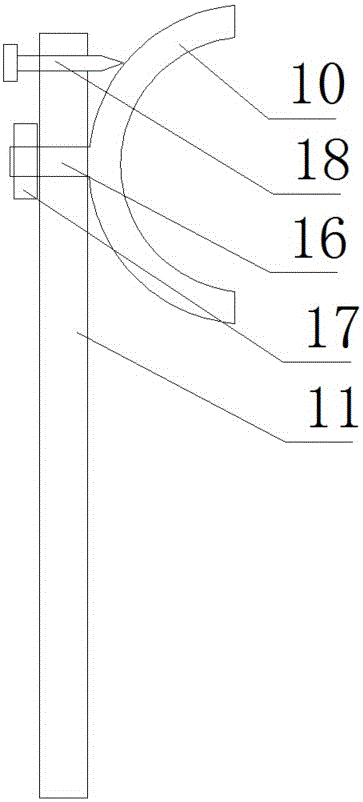

[0027] Such as figure 1 , 2 , 3, the power engineering elbow clamping laser cutting device of the present invention includes a base 1, a housing, a ring gear 3, a laser cutting head 4, a telescoping mechanism 5 and a workpiece clamping mechanism, and the bottom of the housing can pass through the connecting piece 1-1 is connected with the base 1, and for the convenience of installation and maintenance, the housing can be set as a two-body structure in which the body 2 is connected with one side cover 2-1. The side wall of the body 2 and the central part of the cover plate 2-1 are provided with an axial through hole for the pipe to be cut to pass through. The ring gear 3 is movably connected with the housing through a sliding connection mechanism to ensure that the ring gear 3 can rotate freely. The telescopic mechanism 5 is fixedly connected to the position of the ring gear 3 close to the axis through the bracket 6, and the laser cutting head 4 is connected to the telescopic...

Embodiment 3

[0029] Such as figure 1 , 2 , 3, and 4, the power engineering elbow clamping laser cutting device of the present invention includes a base 1, a housing, a ring gear 3, a laser cutting head 4, a telescopic mechanism 5 and a workpiece clamping mechanism, and the bottom of the housing can pass through The connecting piece 1-1 is connected with the base 1, and for the convenience of installation and maintenance, the housing can be configured as a two-body structure in which the body 2 is connected with one side cover plate 2-1. The side wall of the body 2 and the central part of the cover plate 2-1 are provided with an axial through hole for the pipe to be cut to pass through. The ring gear 3 is movably connected with the housing through a sliding connection mechanism to ensure that the ring gear 3 can rotate freely. The telescopic mechanism 5 is fixedly connected to the part of the ring gear 3 close to the axis through the bracket 6, and the laser cutting head 4 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com