Scrap briquetting press discharging mechanism without gate and scrap briquetting press including the same

A technology of discharging mechanism and chip cake machine, which is applied in the direction of presses, manufacturing tools, etc., can solve the problems of difficulty in replacement and maintenance of the block lining plate, easy deformation, etc., and achieves the effect of simple structure, time saving and ingenious thinking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

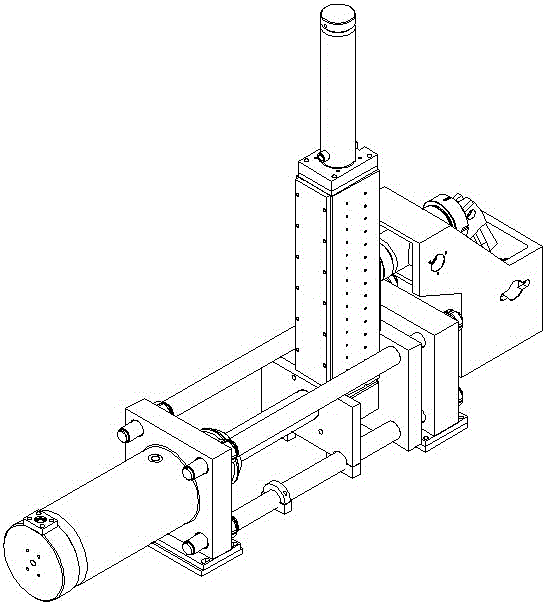

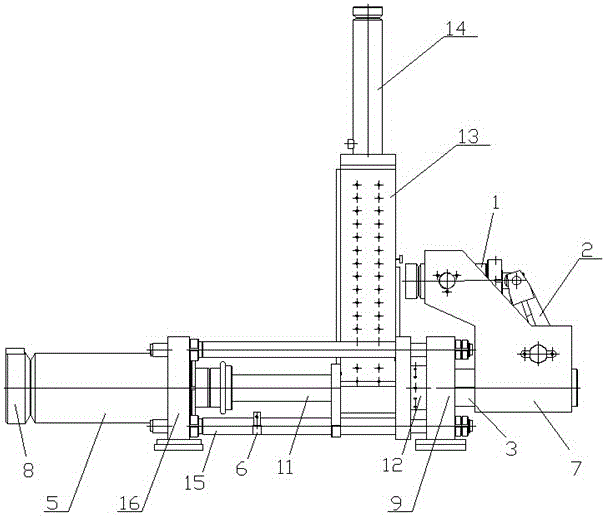

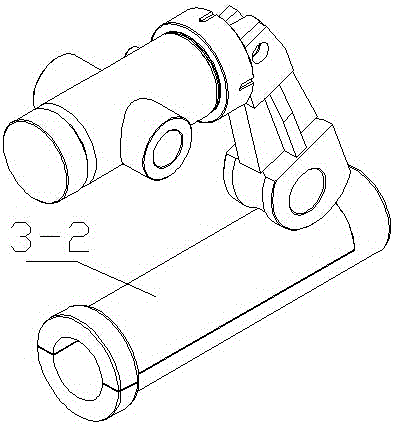

[0025] Such as Figure 1 to Figure 5 As shown, the discharging mechanism of the crumb cake machine without a gate includes a pressing drive device and a cake discharging sleeve 3. The shape of the cake discharging sleeve 3 is a hollow cylinder, and the inner diameter of the cake discharging sleeve 3 is the same as that of the pressing The diameters of the cake blocks are equal, and the cake outlet sleeve 3 is composed of a fixed cake outlet sleeve 3-1 and a movable cake outlet sleeve 3-2, and the movable cake outlet sleeve 3-2 is fixed backward after being acted by a pressing drive device The cake outlet sleeve 3-1 is close to realize the clamping of the cake pieces in the cake outlet sleeve 3. The compression driving device is a clamping cylinder 1 and a mandrel 2. The mandrel 2 is arranged between the clamping cylinder 1 and the pie sleeve 3. The exposed end of the piston rod 4 of the clamping cylinder 1 is hinged with one end of the mandrel 2. , The other end of the ejector...

Embodiment 2

[0028] The difference from the first embodiment is: Image 6 , Figure 7 As shown, the pressing driving device is a clamping cylinder 1, and the exposed end of the piston rod 4 of the clamping cylinder 1 is fixedly connected with the arc outer surface of the cake outlet sleeve 3. The exposed end of the piston rod 4 of the clamping cylinder 1 is fixedly connected to the arc outer surface of the cake outlet sleeve 3. The length of the cake outlet sleeve 3 is greater than the thickness of the two cake blocks, and the position where the exposed end of the piston rod 4 of the clamping cylinder 1 and the arc outer surface of the cake outlet sleeve 3 are fixedly connected is at the head of the discharge port.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com