Intelligent remote-controlled four-wheel-drive plant protection machinery and control method thereof

An intelligent remote control and plant protection technology, applied in the field of agricultural machinery, can solve the problems of failure of the steering gear or motor, poor passability of crops in the field, insufficient torque of the wheel hub motor, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

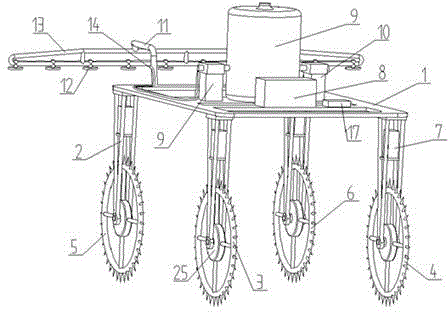

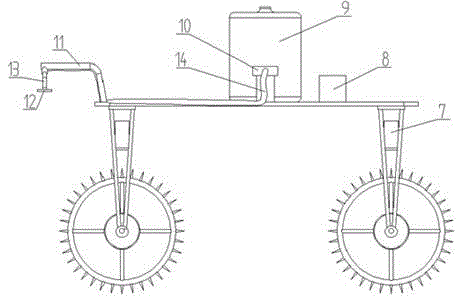

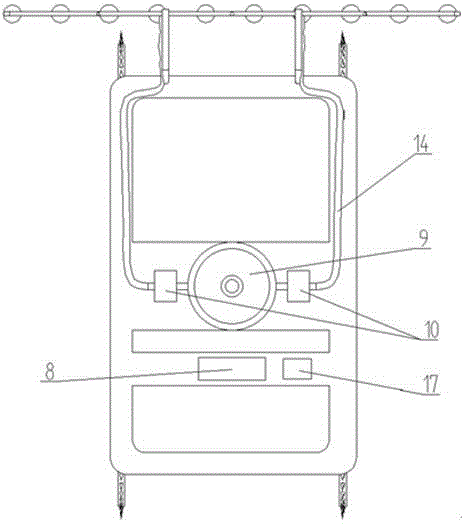

[0035] Such as figure 1 , figure 2 , image 3 As shown, this embodiment adopts a brushless toothed motor 25 for driving. Wheel bracket 2 is installed on the bottom of vehicle frame 1; Left front wheel 3, right front wheel 4, left rear wheel 5, right rear wheel 6 are respectively installed on respective wheel bracket 2; On the four wheels of front wheel 3, right front wheel 4, left rear wheel 5, right rear wheel 6; Motor battery 7 is installed on four wheel supports 2 respectively, and motor battery 7 is respectively connected with the four wheels by wire The toothed brush motor 25 is connected to provide power for the operation of the brushless toothed motor 25; the pump battery 8, the medicine box 9, the pump 10, the spray rod bracket 11, and the main controller 17 are all installed on the top of the vehicle frame 1; the pump battery 8 is connected with the pump 10 by wires; the spray bar bracket 11 is installed on the rear of the vehicle frame 1; the spray bar 13 is inst...

Embodiment 2

[0038] Such as Figure 4 As shown, the difference from Embodiment 1 is that the drive mode is driven by a central motor 15, and the transmission mechanism uses a chain 19 to drive the wheels to rotate. Each middle motor 15 is equipped with one and the middle motor driver 16 and the two are connected with wires, and both are installed on the motor mount in the middle of each wheel support 2; On the rotating shaft, the large sprocket 20 is connected with each driving wheel by the shaft, and the small sprocket 18 is connected with the large sprocket 20 with a chain 19; each middle motor 15 is equipped with an independent motor battery 17, and the motor battery 17 is installed on Each wheel bracket 2 is directly above the vehicle frame 1 .

[0039] When the middle motor 15 rotates, the chain 19 is driven by the small sprocket 18, and the chain 19 drives the large sprocket 20 to rotate, and the large sprocket 20 drives each wheel to run. For other specific implementation manners,...

Embodiment 3

[0041] Such as Figure 5 As shown, the difference of this embodiment is that the chain transmission mechanism in the second embodiment is a shaft transmission mechanism. The transmission gearbox is fixed on the front wheel bracket 2, the middle motor 15 is fixed on the transmission gearbox, the first gear of the transmission gear 21 is fixed on the rotating shaft of the middle motor 15, and the gear at the end of the transmission gear 21 is Fixed transmission shaft 22, transmission shaft 22 runs through front wheel support 2, and the bottom end is fixed with transmission bevel gear 23, and driven bevel gear 24 is installed on each wheel by rotating shaft, and transmission bevel gear 23 meshes.

[0042] When the center motor 15 rotates, the transmission gear 21 drives the transmission shaft 22 to rotate. When the transmission shaft 22 rotates, the transmission bevel gear 23 at the bottom drives the driven bevel gear 24 to rotate, thereby driving the wheel to rotate. For other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com