Electric folding forklift remotely controlled and operated through WiFi

A technology of remote control operation and folding fork, which is applied in the direction of lifting device, etc., which can solve the problems of large footprint, large volume, and heavy weight, and achieve the effect of reducing the weight of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be further described below in conjunction with the accompanying drawings and examples.

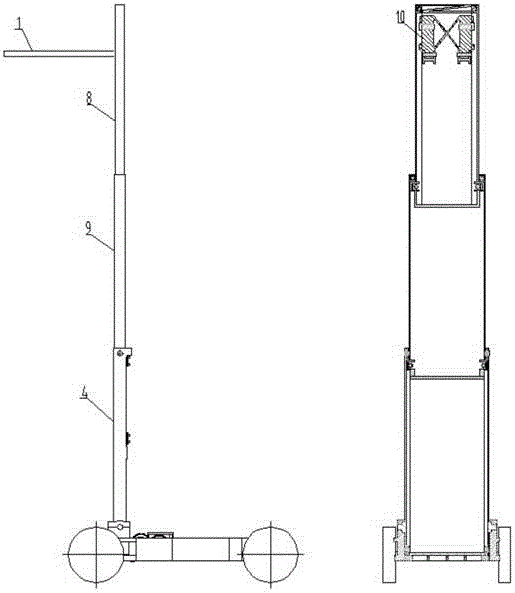

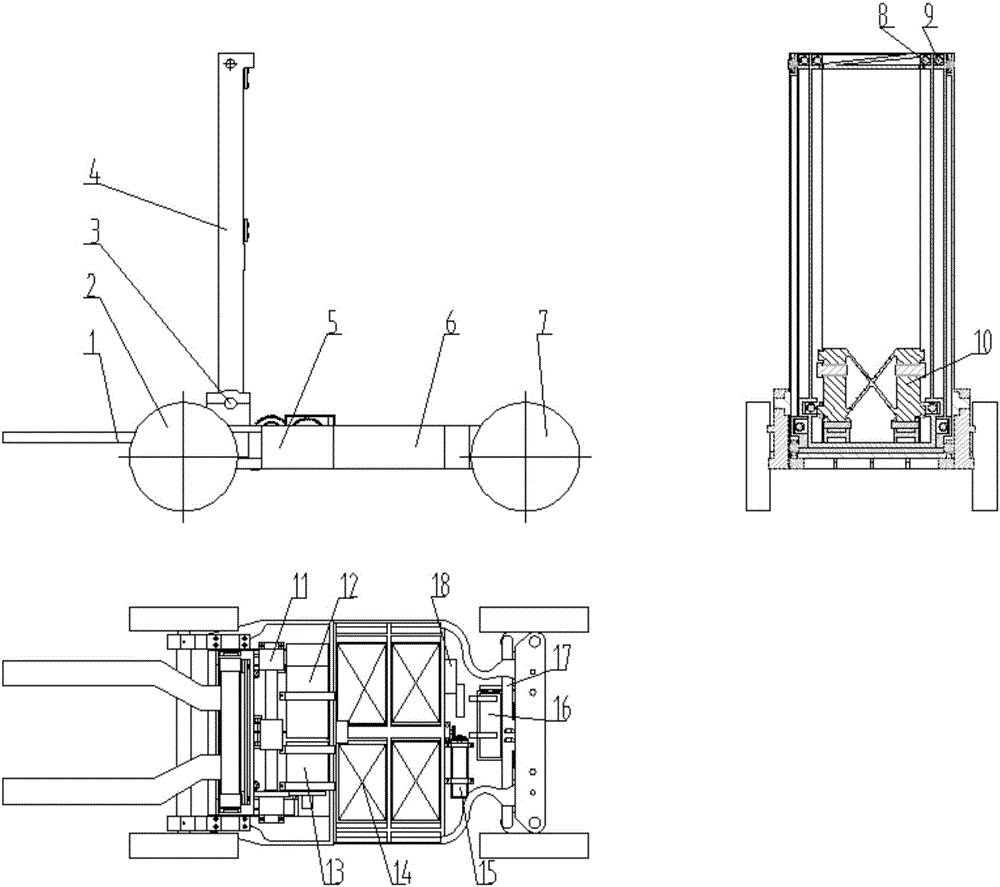

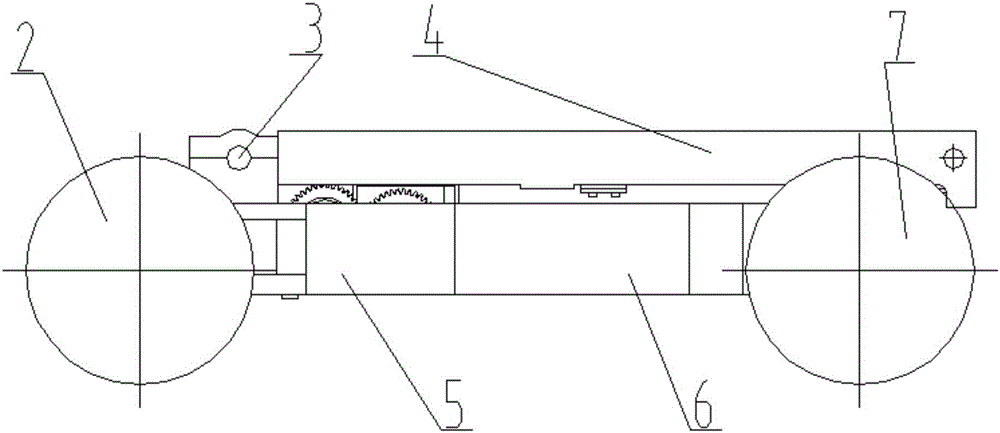

[0018] Lifting mechanism

[0019] During the working process of an electric folding forklift operated by remote WiFi remote control, the lifting mechanism can ensure that the fork (1) moves linearly along the fixed guide rail (4), the secondary guide rail (9) and the tertiary guide rail (8) to achieve different heights Loading and unloading of goods. Lifting mechanism is mainly made up of motor (12), speed reducer (13), winch barrel (11) and gear. The two ends of the wire rope are respectively connected with the cargo fork () and the winch (11), and the winding direction of the wire ropes on the ascending winch and the descending winch is opposite. Its working principle is: the motor (12) drives the reducer (13) to drive the winch bucket (11) mechanism to work, thereby realizing the vertical lifting of the cargo fork (1). When the cargo rises, the fork (1) firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com