Method for preparing high-thermal-stability insoluble sulfur by using aromatic hydrocarbon end-capping agent containing carbocation structure

A technology with high thermal stability and carbocations, which is applied in the preparation/purification of sulfur, can solve the problems of thermal stability only between 42% and 45%, poor thermal stability of insoluble sulfur, and return to the original, and achieve reduction The effect of production cost, reduction of addition amount, and small usage amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

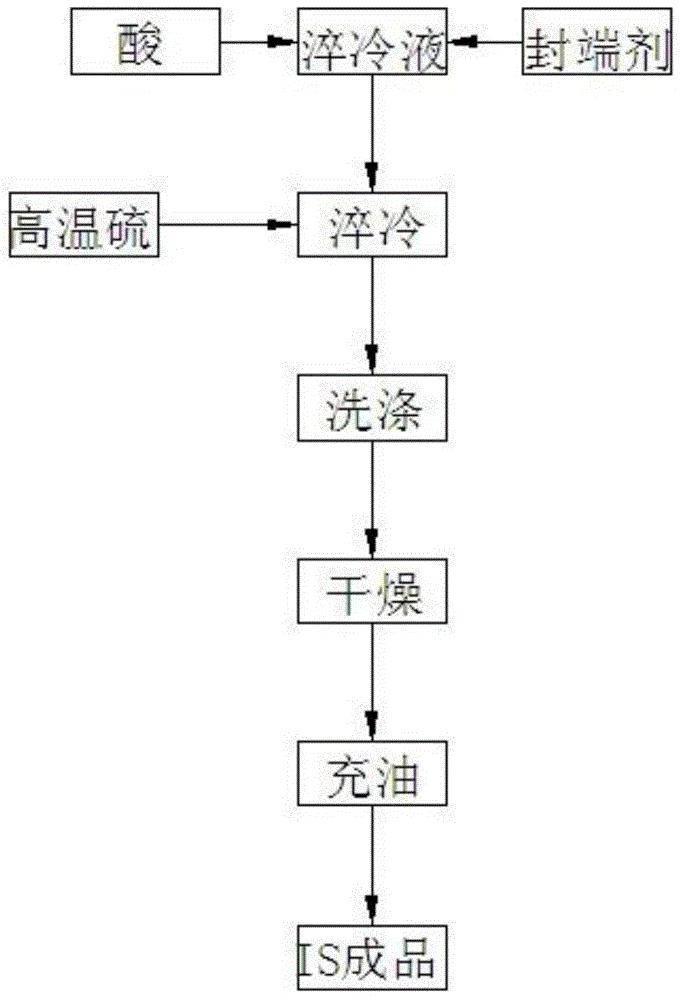

Image

Examples

Embodiment 1

[0017] Embodiment 1. Add 0.1% (relative to the quenching liquid) triphenylphosphine into the quenching liquid, mix well, add 0.05% concentrated nitric acid, and mix for 30 minutes. Carry out end-capping reaction, then carry out washing, drying and oil-filling treatment to obtain insoluble sulfur finished product.

Embodiment 2

[0018] Example 2: Add 1.0% (relative to the quenching liquid) trityl alcohol into the quenching liquid, mix well, add 0.5% concentrated sulfuric acid, and mix for 30 minutes. Carry out end-capping reaction, then carry out washing, drying and oil-filling treatment to obtain insoluble sulfur finished product.

Embodiment 3

[0019] Example 3: Add 1.5% (relative to the quenching liquid) triphenylmercaptan into the quenching liquid, mix well, add 1.0% concentrated hydrochloric acid, and mix for 30 minutes. Carry out end-capping reaction, then carry out washing, drying and oil-filling treatment to obtain insoluble sulfur finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com