A kind of preparation method of halogenated polymer

A technology for compounds and copolymers, applied in the field of preparation of halogenated polymers, can solve the problems of unsatisfactory, high technical requirements for aluminoxane preparation, difficult preparation of initiator systems, etc., so as to reduce energy consumption and improve polymerization efficiency. , the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

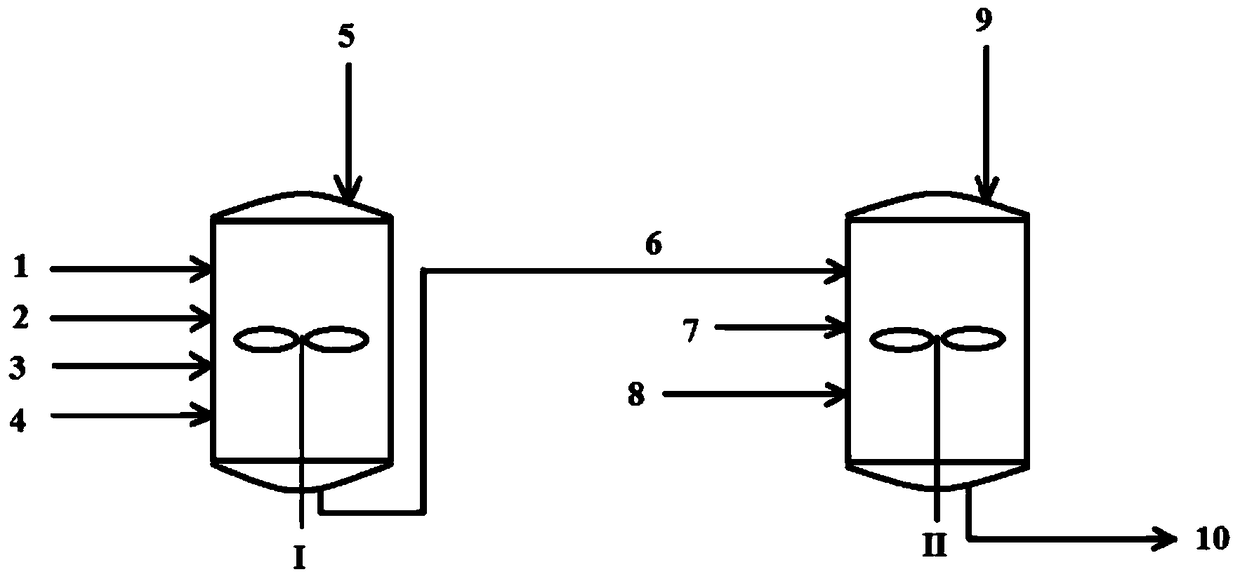

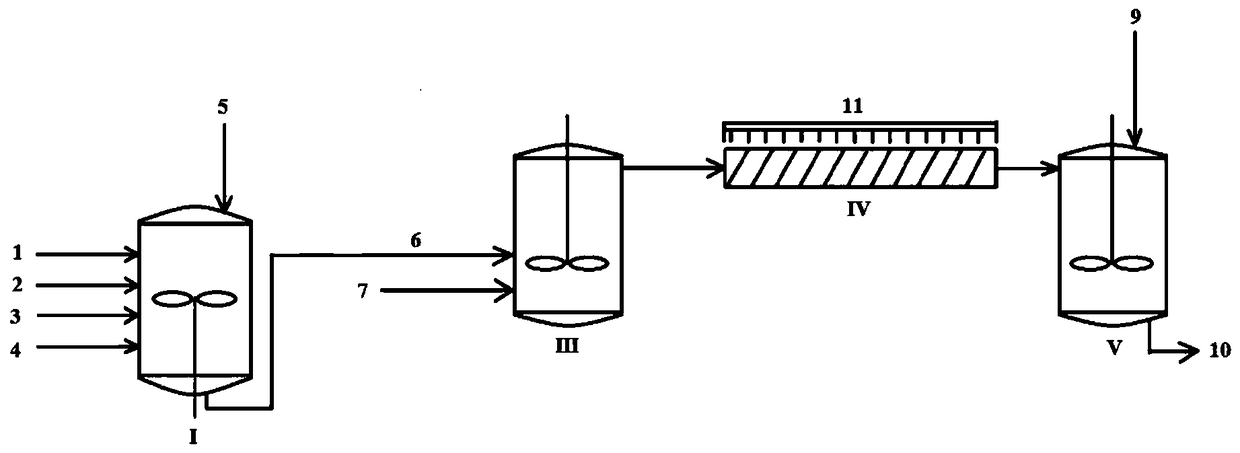

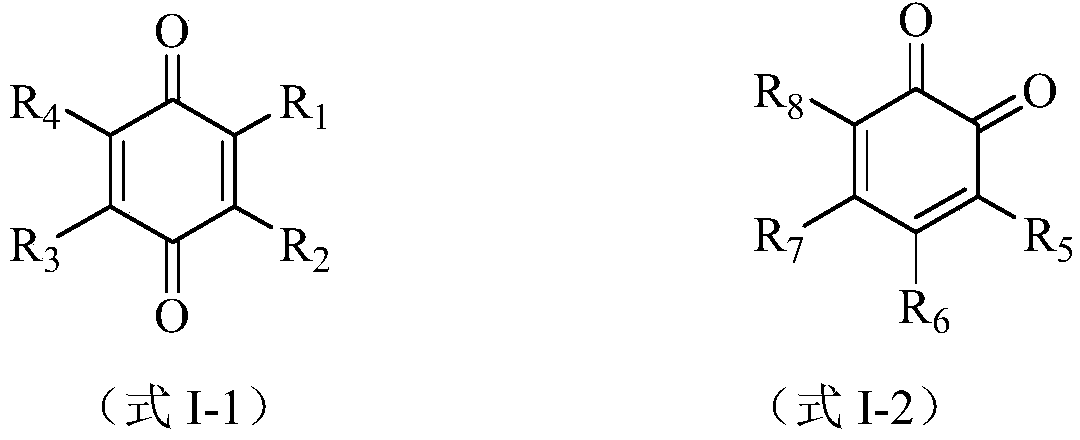

[0036] The invention provides a kind of preparation method of halogenated monoolefin-alkylstyrene copolymer, the method comprises the following steps:

[0037] (1) Under cationic polymerization conditions, in at least one polymerization solvent, at least one monoolefin and at least one alkylstyrene are contacted with each component in the initiator system to obtain monoolefin-alkylbenzene-containing The solution of ethylene copolymer, described polymerization solvent is selected from alkane, the condition of described contact makes, by weight, the content of the unreacted alkylstyrene in the described solution that contains monoolefin-alkylstyrene copolymer is Not higher than 1000ppm, preferably not higher than 500ppm, more preferably not higher than 200ppm;

[0038] (2) The solution containing the monoolefin-alkylstyrene copolymer obtained in step (1) is contacted with a halogen-containing compound, so that part of the hydrogen atoms in the molecular chain of the monoolefin-alk...

experiment example 1

[0115] (1) 0.0532g 2,3-dichloro-5,6-dicyano-p-benzoquinone is dissolved in 66.3g and contains HCl (concentration is 0.0037mol / L) in the dichloromethane solution, the solution obtained is pre- Cool to -85°C, and then sequentially add 3.2 mL of 0.9 mol / L ethylaluminum dichloride (EADC) n-hexane solution and 1.2 mL of 1.0 mol / L diethylaluminum chloride to the solution (DEAC) n-heptane solution, after mixing evenly, place the obtained mixed solution in a cold bath at -85° C. to age for 100 min, thereby obtaining an initiator solution. Wherein, by weight, the content of 2,3-dichloro-5,6-dicyano-p-benzoquinone in the initiator solution is 770ppm.

[0116] (2) Place a 250mL three-necked flask in a low-temperature cooling bath whose temperature is controlled from -80°C to -85°C, and add 85mL of n-hexane cooled to -80°C, 15mL of isobutylene cooled to -80°C and 0.62 mL of normal temperature (25° C.) p-methylstyrene (98% by weight) was mixed uniformly to obtain a monomer solution. Add ...

experiment example 2

[0120] Polymerization was carried out in the same manner as in Experimental Example 1, except that diethylaluminum chloride was not used in step (1), and diethylaluminum chloride was replaced by ethylaluminum dichloride in an equimolar amount. The experimental results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com