A multi-material composite carbon fiber sound-insulating floor for ships and its preparation method

A carbon fiber, composite technology, applied in chemical instruments and methods, ship hulls, ship construction, etc., can solve the problems of reducing the comfort of ships, submarine concealment, high noise, etc., achieve good sound insulation, reduce waste, and can be adjusted in size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

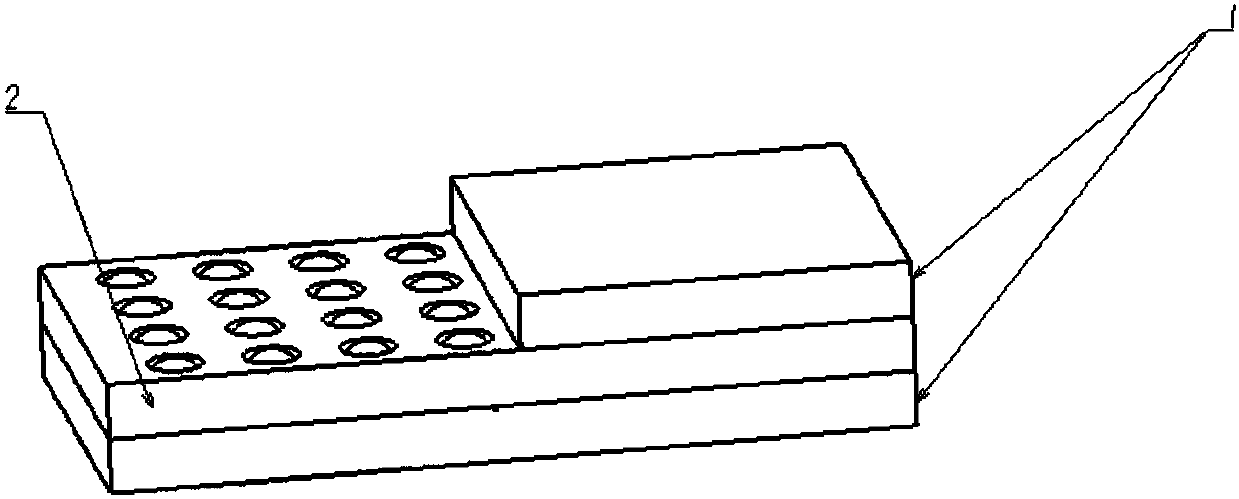

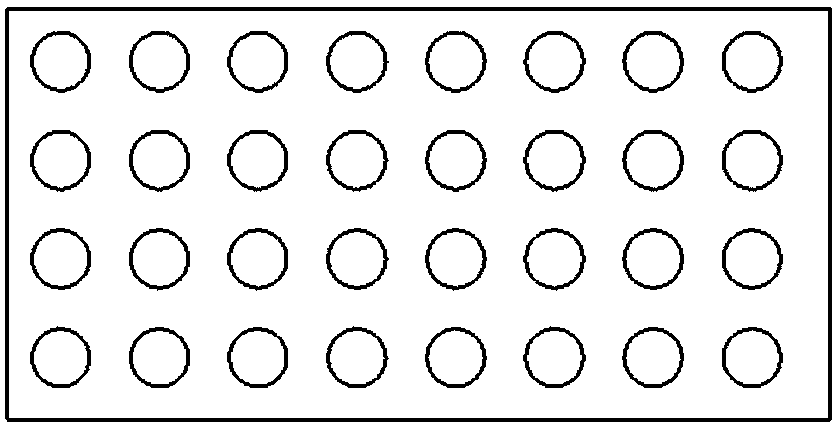

[0024] A multi-material composite carbon fiber sound-insulating floor for ships provided by the present invention is mainly composed of a sound-insulation composite layer 1 and a load-bearing carbon fiber layer 2, see figure 1 . Among them, the sound insulation composite layer 1 is composed of a silicone rubber plate with holes and a hollow resin ball embedded in the holes according to certain geometric rules, see figure 2 The load-bearing carbon fiber layer 2 is obtained by curing prepregs of carbon fiber epoxy resin-based composite materials. Wherein, the holes are uniformly arranged in a matrix. The diameter of the small ball is consistent with the thickness of the silicone rubber plate.

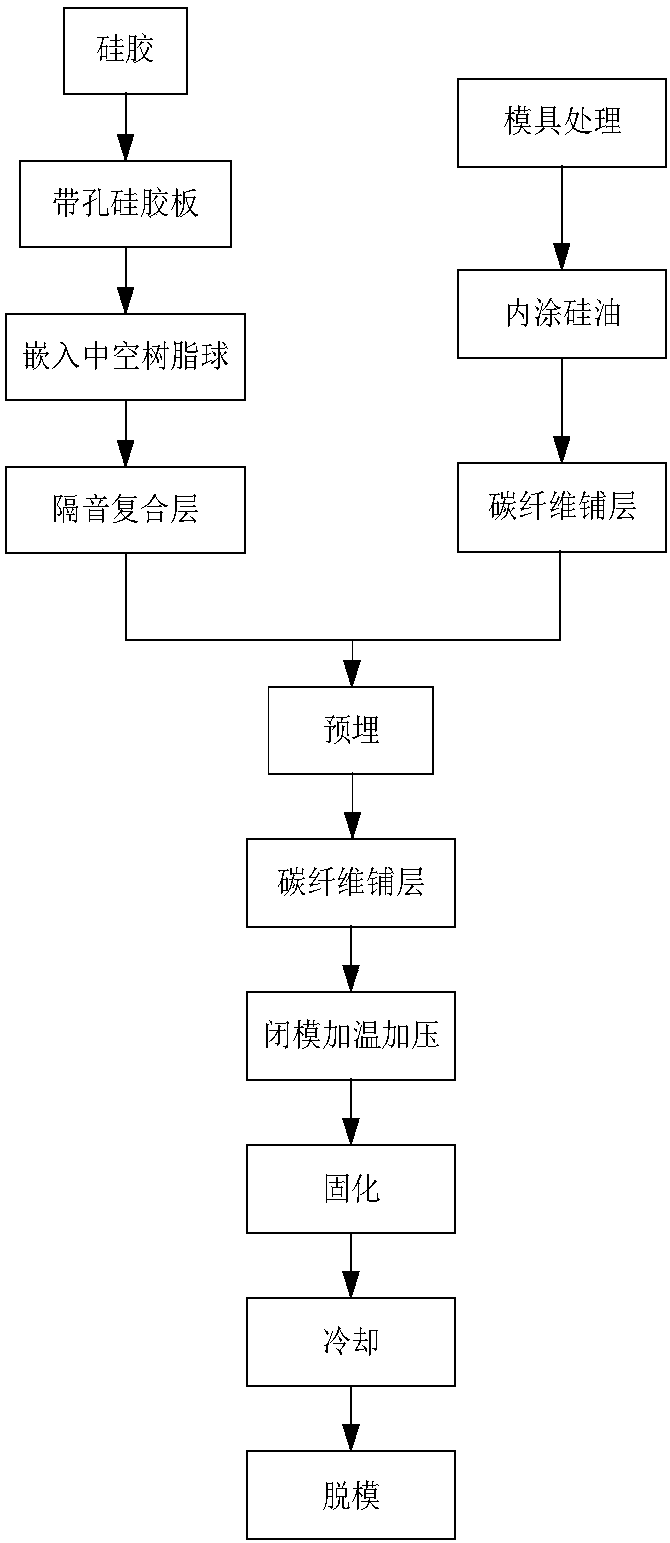

[0025] The preparation process of the present invention will be further described in detail below in conjunction with the accompanyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com