Prefabricated bridge deck expansion joint connection member, manufacturing method and construction method of prefabricated bridge deck expansion joint connection member

A technology for connecting components and expansion joints, used in bridge parts, bridges, bridge construction, etc., can solve the problems of loss of filler, poor deformation capacity, and damage to the bridge's stressed structure, and achieve novel structural design, high toughness, and resistance to expansion and contraction. The effect of strong seam deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described below in conjunction with specific embodiments.

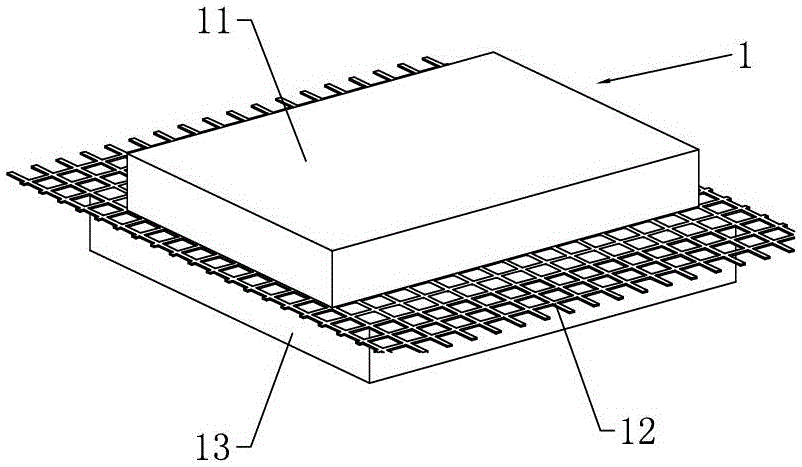

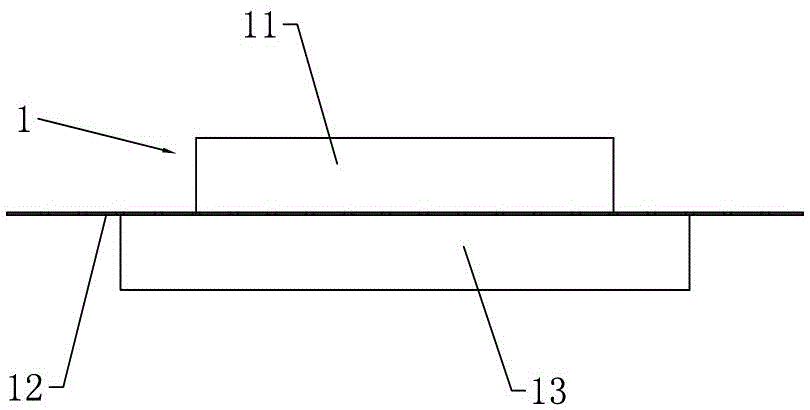

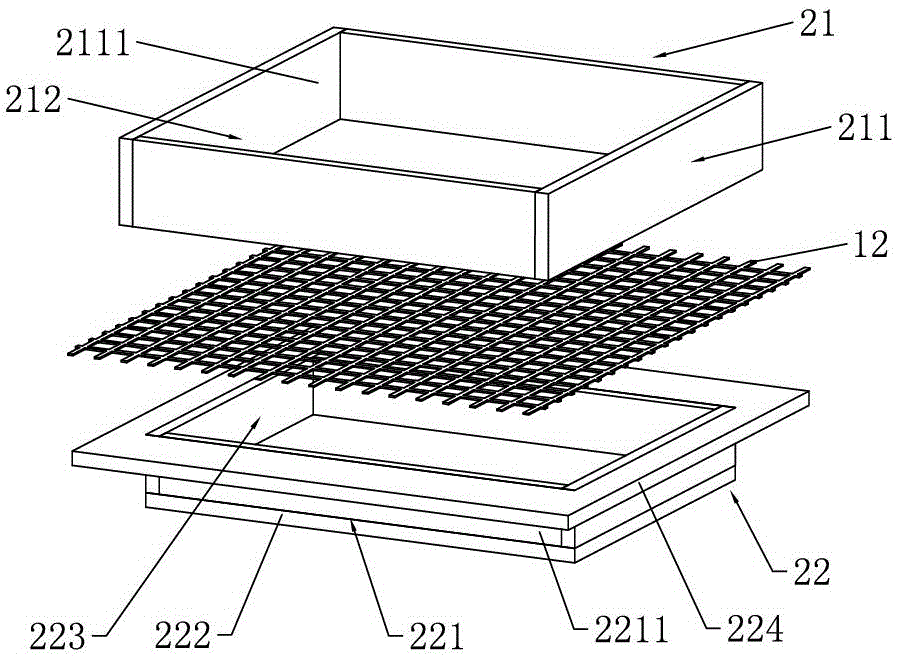

[0051] Such as figure 1 and figure 2 As shown, a prefabricated bridge deck expansion joint connection member includes an upper ECC cement-based composite material layer 11, an FRP fiber reinforced composite grid 12, a lower ECC cement-based composite material layer 13, and an upper end The front end surface of the ECC cement-based composite material layer 11 is aligned with the front end surface of the lower ECC cement-based composite material layer 13, and the rear end surface of the upper ECC cement-based composite material layer 11 is aligned with the rear end surface of the lower ECC cement-based composite material layer 13. Arrangement, the left end of the lower ECC cement-based composite material layer 13 extends to the left end side of the left end face of the upper ECC cement-based composite material layer 11, and the right end of the lower ECC cement-based composite mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com