Exterior wall construction process of dry wall

A construction technology and exterior wall technology, which is applied to building components, climate change adaptation, and climate sustainability. The effect of construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

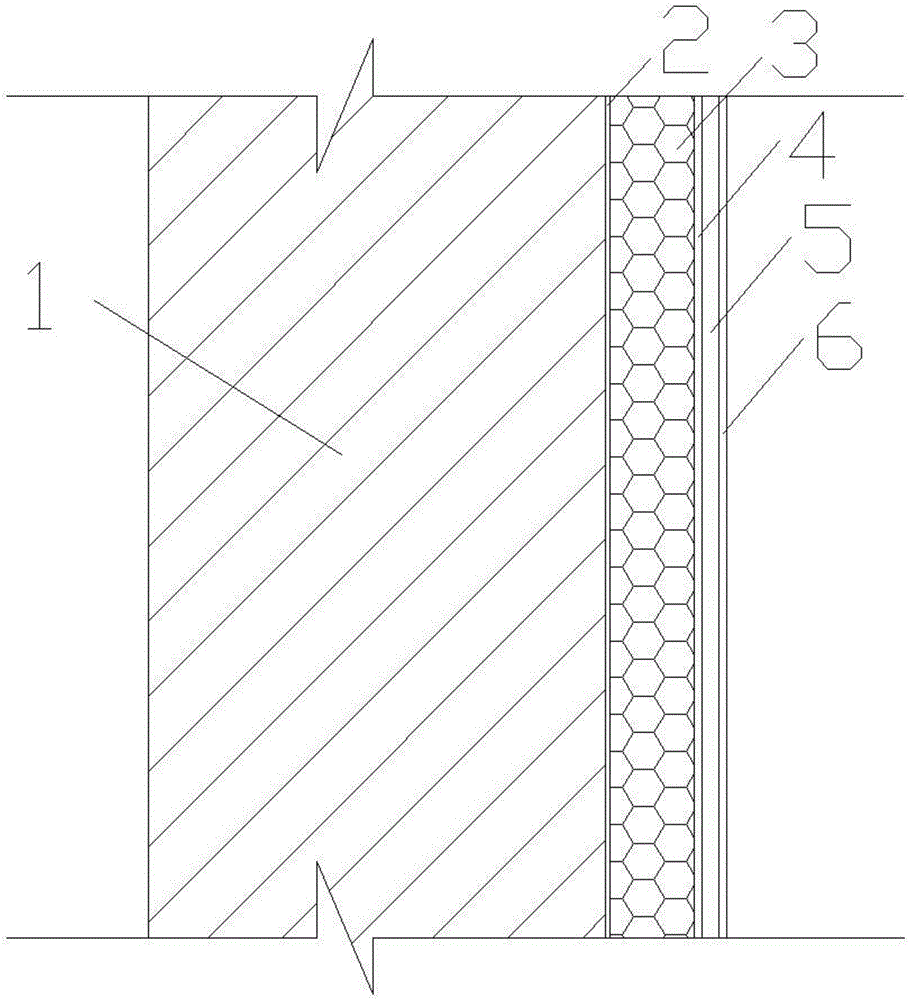

[0019] Such as figure 1 Shown, the exterior wall construction technique of described dry wall comprises the steps:

[0020] Base wall 1 cleaning: the pre-buried pipes (pieces) protruding from the outer wall of base wall 1 have been installed and the thickness of the insulation layer has been reserved; the holes in the scaffolding joints and the wall defects have been repaired; the walls should be clean , no oil stains and floating ash; loose and weathered parts should be removed; the flatness and verticality of the base wall 1 should meet the specification requirements, so as to avoid partial insufficient thickness of polyurethane spraying; before spraying polyurethane insulation layer 3, door and window frames, scaffolding and non-insulation should be done Part of the occlusion work.

[0021] Hanging vertical line: After the base treatment, in o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com