Supercharger with combined sealing structure of double-sided turbine

A double-sided turbine and combined sealing technology, which is applied in the direction of machines/engines, leakage prevention, engine components, etc., can solve the problems of reduced efficiency and poor matching characteristics of compressors, etc., to increase work capacity and reduce gas leakage , the effect of wide matching range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

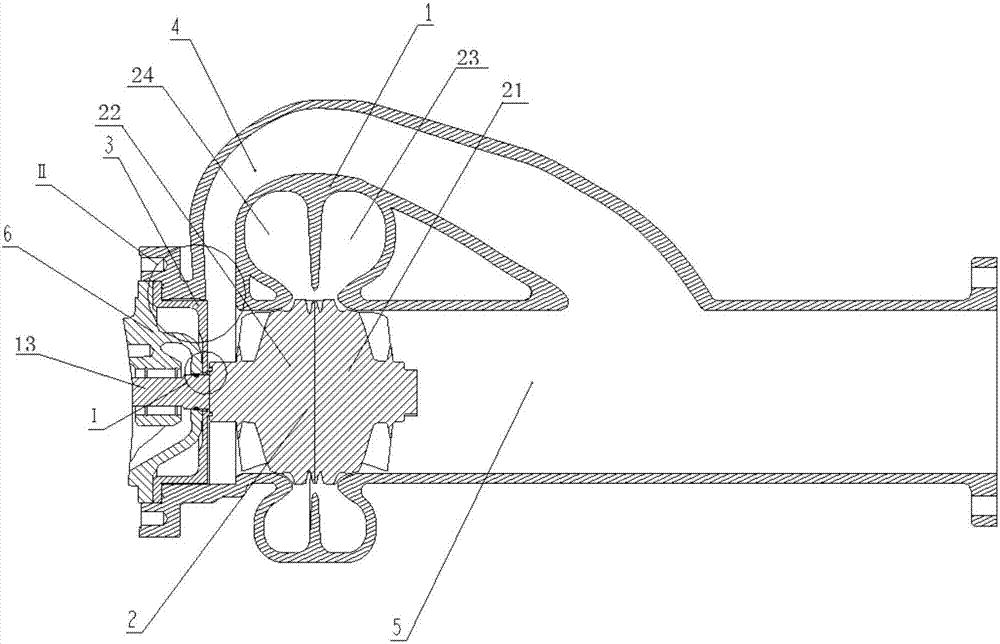

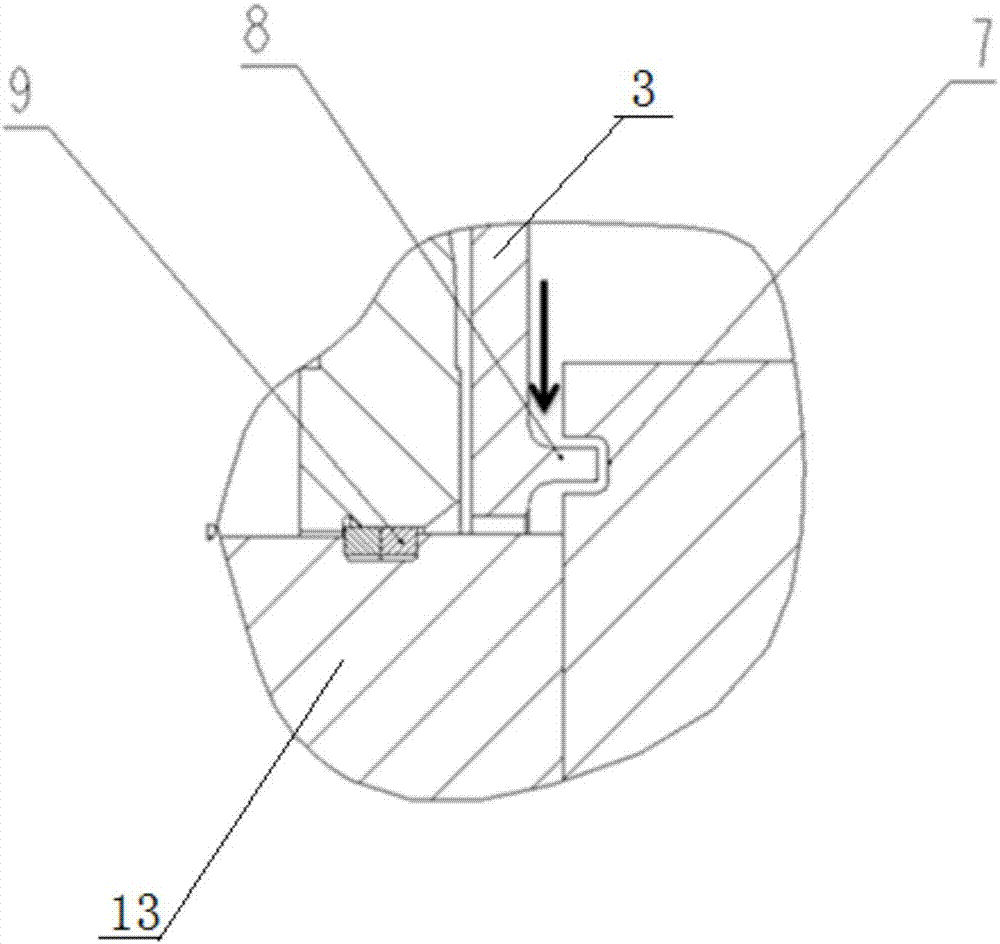

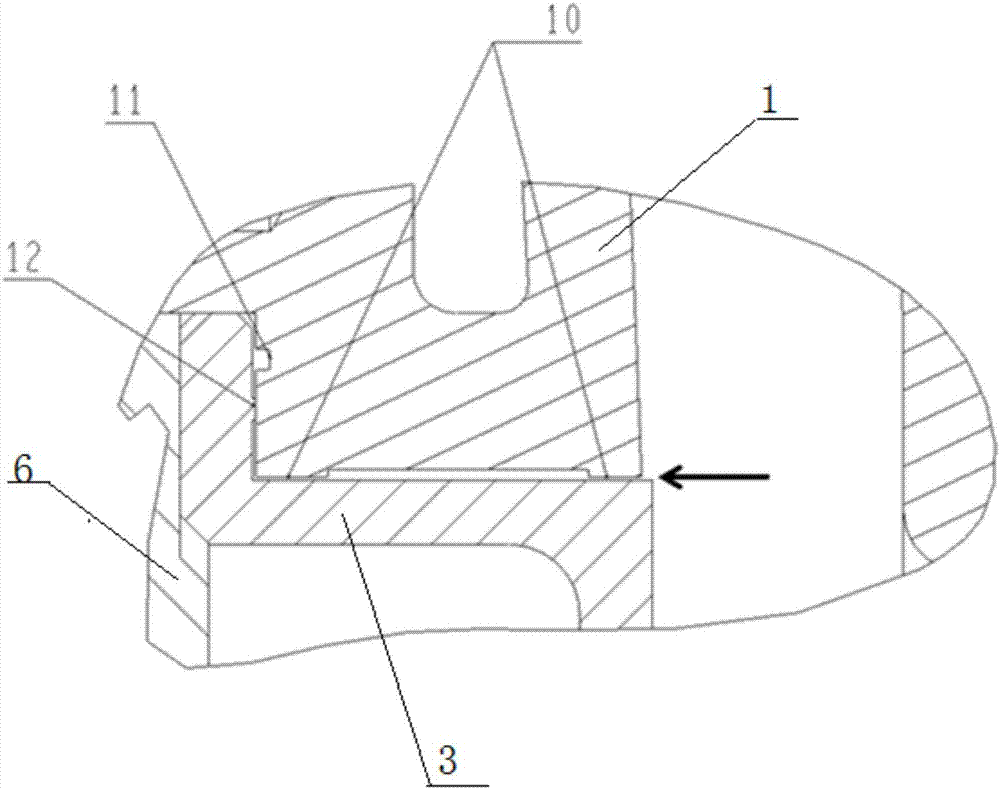

[0022] A supercharger with a double-sided turbo, such as figure 1 As shown, it includes a turbine box 1 and a double-sided turbine 2 installed therein. The double-sided turbine 2 is composed of two back-to-back turbines, which are respectively the first turbine 21 and the second turbine 22; the turbine box 1 is provided with Inlet flow path and outlet flow path, the output ends of the first turbine 21 and the second turbine 22 are respectively provided with the first turbine exhaust passage 5 and the second turbine exhaust passage 4 for exhaust, the first turbine The exhaust passage communicates with the second turbine exhaust passage at the end;

[0023] The first turbine 21 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com