Fault detecting and processing method for continuous variable valve lift mechanism

A fault handling method and valve lift technology, applied in electrical control, mechanical equipment, engine control, etc., can solve problems such as wrong judgment results, motor heating, burning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

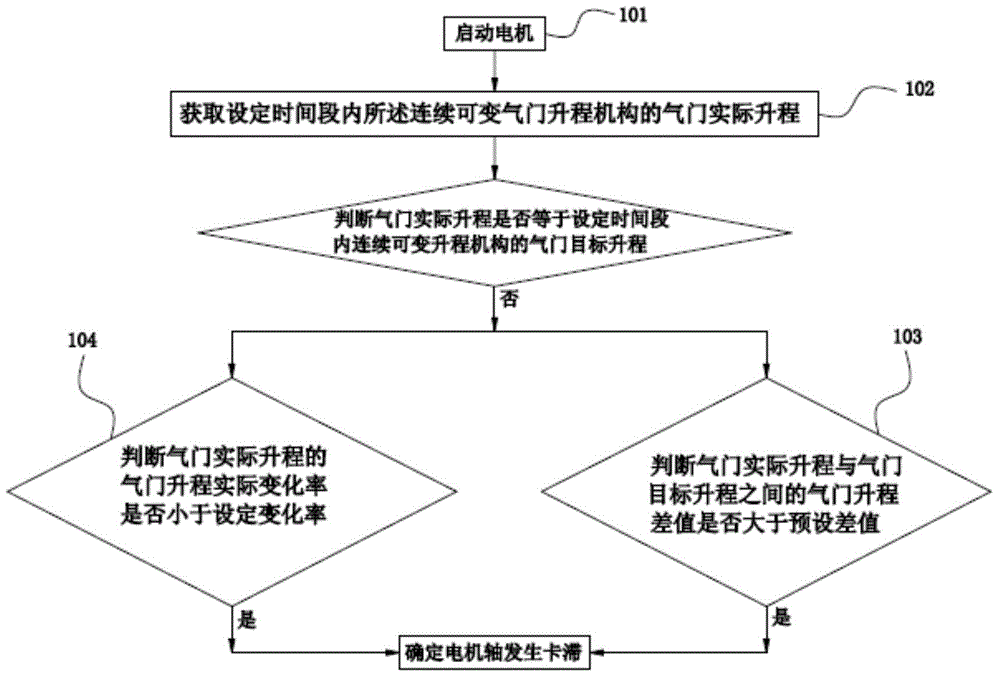

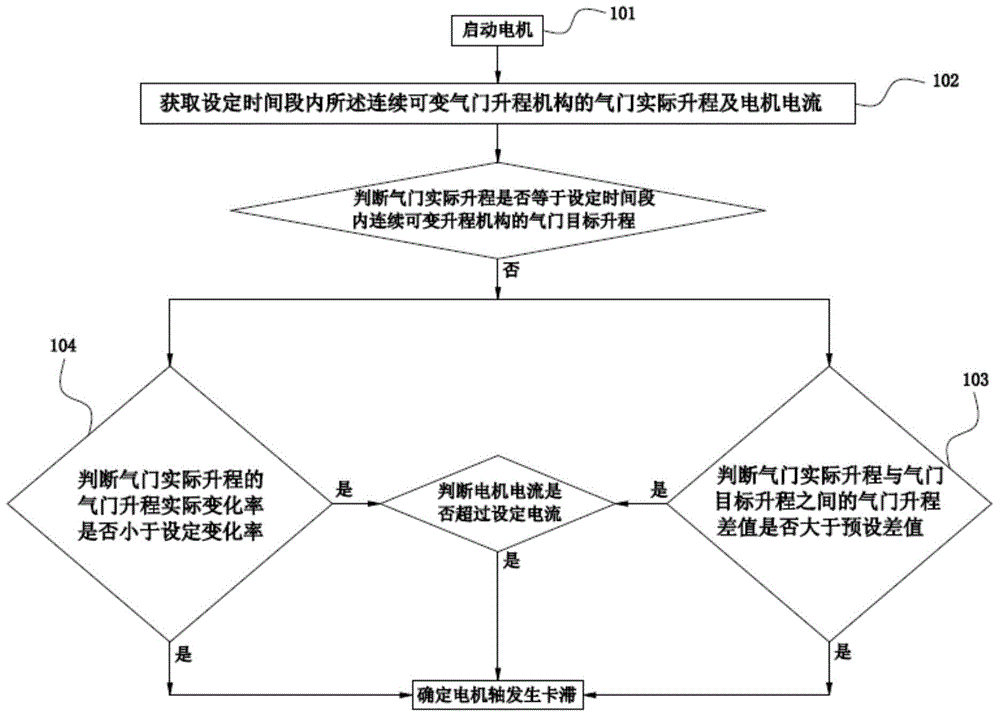

[0044] This embodiment provides a fault detection method for a continuously variable valve lift mechanism, wherein the continuously variable valve lift mechanism includes a control unit, a motor, a valve and a sensor for sensing the actual lift of the valve, such as figure 1 As shown, the fault detection method includes:

[0045] Step 101, start the motor;

[0046] Step 102, obtaining the actual valve lift of the continuously variable valve lift mechanism within a set time period;

[0047]Step 103, when the actual valve lift is not equal to the target valve lift of the continuously variable valve lift mechanism within the set time period, and the valve lift difference between the actual valve lift and the valve target lift is greater than the preset difference value to determine that the motor shaft of the motor is stuck; or

[0048] Step 104, when the actual valve lift is not equal to the target valve lift of the continuously variable valve lift mechanism within the set tim...

Embodiment 2

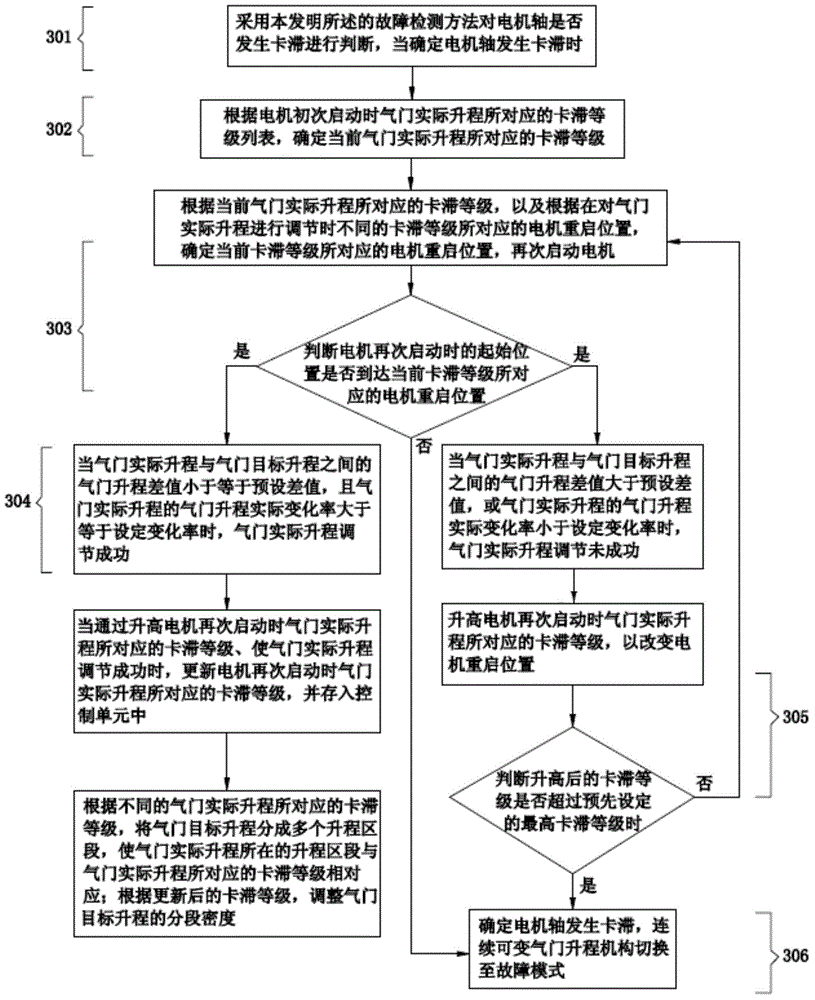

[0053] This embodiment is a method for troubleshooting a continuously variable valve lift mechanism, such as image 3 As shown, the troubleshooting methods include:

[0054] Step 301 , using the fault detection method in the first embodiment above to judge whether the motor shaft is stuck; when it is determined that the motor shaft is stuck, execute step 302 . For the detection method of whether the motor shaft is stuck, please refer to the first embodiment above, which will not be repeated here.

[0055] Step 302 , according to the sticking level list corresponding to the actual valve lift when the electric motor is started for the first time, determine the sticking level corresponding to the current actual valve lift.

[0056] Step 303, according to the sticking level corresponding to the current actual valve lift, and according to the motor restart position corresponding to different sticking levels when the actual valve lift is adjusted, determine the motor restart positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com