Low-noise cooling fan for train

A cooling fan, low noise technology, applied in mechanical equipment, machine/engine, liquid fuel engine, etc., to achieve the effect of reducing eddy current noise, reducing noise pollution, and reducing the separation area of the outlet section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

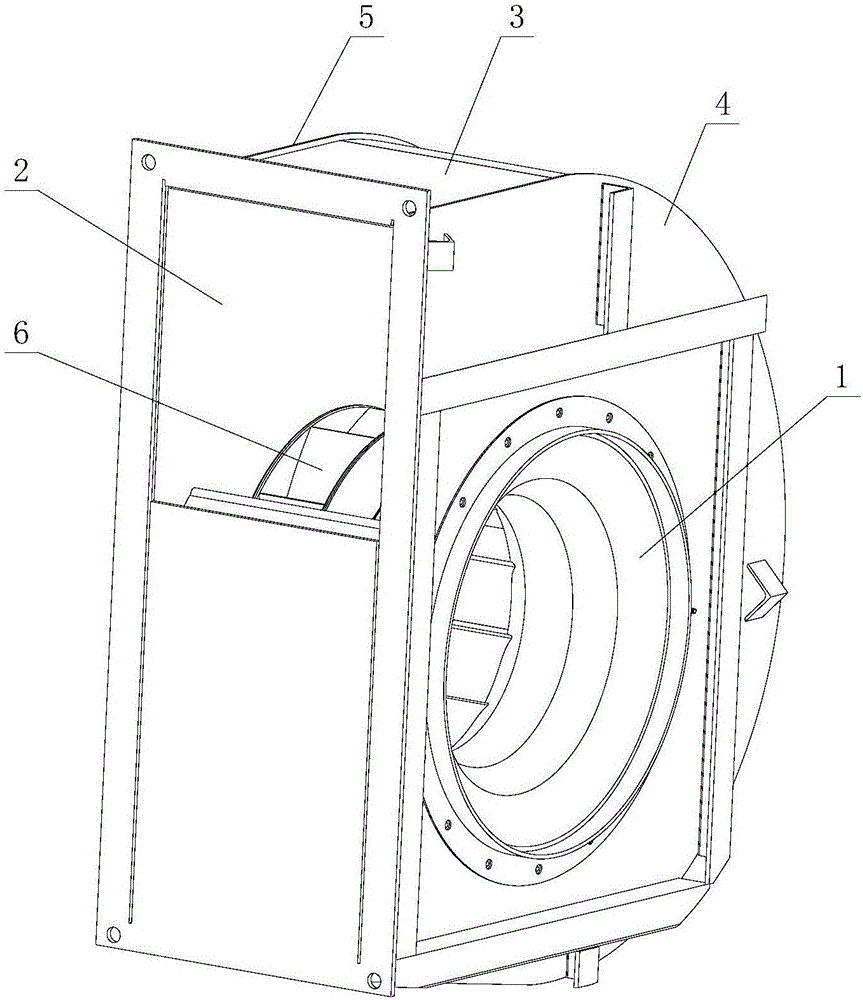

[0021] like Figure 1~6 The shown low-noise cooling fan for trains includes a volute, an air inlet 1, an air outlet 2 and an impeller, the volute includes a side plate and a worm plate 3, the side plate includes a front side plate 4 and a rear side plate 5, and the impeller Including front disk, rear disk, wheel hub and blade 6.

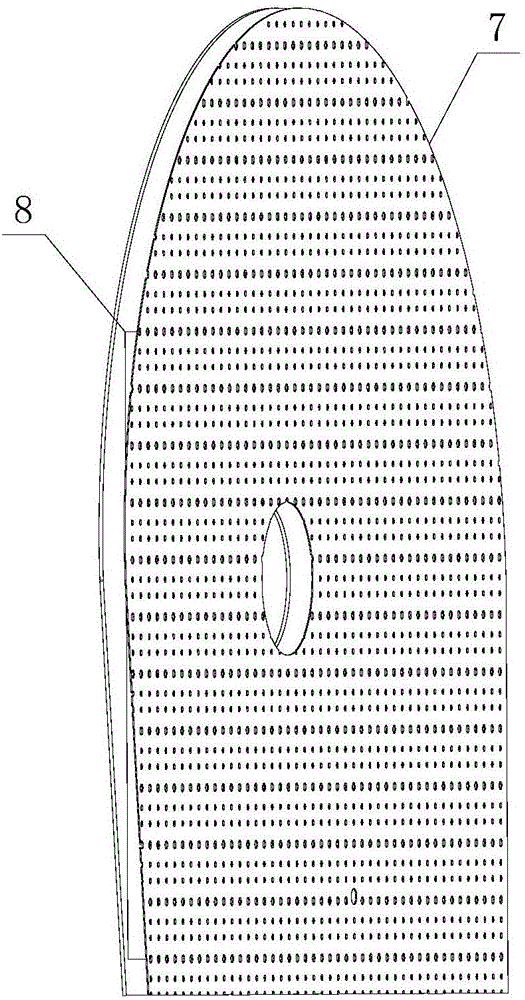

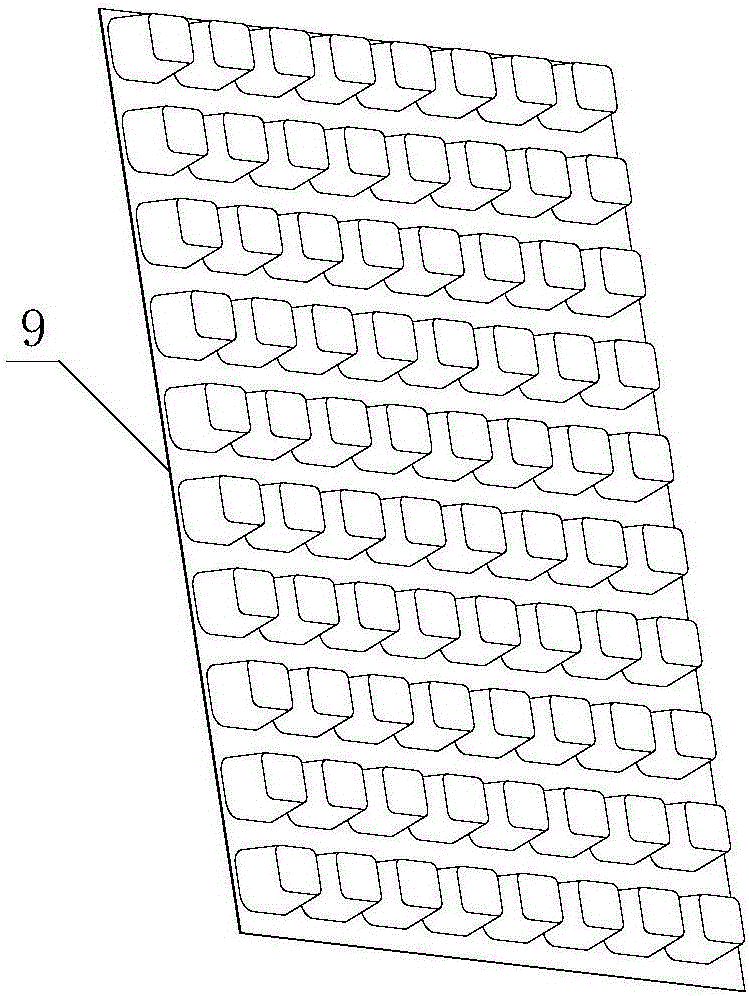

[0022] There is a combined micro-perforated plate 7 in the inner gap of the side plate. The combined micro-perforated plate 7 is a plate with micro-holes of two different sizes, which form a resonant sound-absorbing body with the cavity respectively. The body 7 has a larger sound-absorbing bandwidth than a sound-absorbing body with an aperture, and has a better noise reduction effect. A supporting plate 8 for connection is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com