Large-diameter reinforced concrete pipeline traction type matching method

A reinforced concrete, large-diameter technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problem of pipeline elevation and axis deviation, improper butt joint ends of pipe joints, and affect the service life of pipelines, etc. problem, to achieve the effect of fast matching, labor saving, and simple matching method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

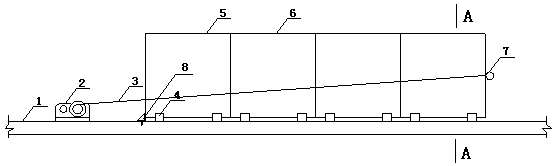

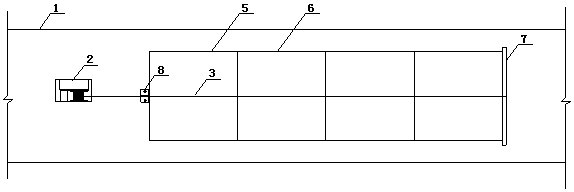

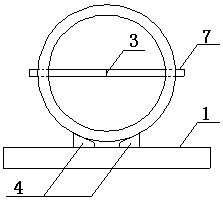

[0036] see now Figure 1-3 , figure 1 It is a schematic diagram of the elevation of the large-diameter reinforced concrete pipeline traction type counterpart operation in the embodiment of the present invention, figure 2 It is a schematic plan view of the traction-type counterpart operation of a large-diameter reinforced concrete pipeline in an embodiment of the present invention, image 3 for figure 1 A-A sectional view in .

[0037] The large diameter reinforced concrete pipeline traction type counterpart method of the present invention is characterized in that comprising the following steps:

[0038] a. Pop up the longitudinal centerline of the pipeline to be installed and the transverse starting line of the first section of pipeline 5 on the reinforced concrete bottom plate 1.

[0039] b. Install the hoist 2 on the reinforced concrete bottom plate 1, and make the center line of the hoist drum coincide with the longitudinal center line of the ejected pipe; the hoist 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com