Novel organic waste gas combustion purifying device

An organic waste gas and purification device technology, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of increasing the complexity of the purification device system, increasing the investment and operating costs, and the uneconomical recovery method, and achieving no secondary production. Contamination, ease of use and maintenance, low concentration range effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

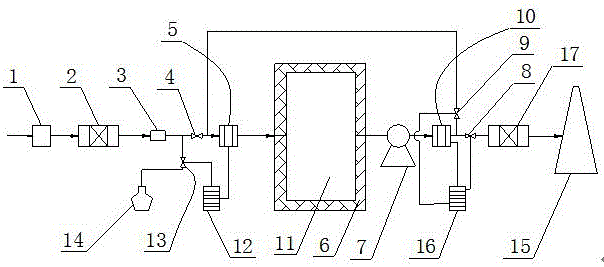

[0014] Specific embodiment one, please refer to figure 1 , a new type of organic waste gas combustion purification device, comprising a water vapor remover 1, a filter 2, a concentration monitor 5, a fan 7, a filter 17, an exhaust passage 15, a burner 11 and a valve 4 13, its It is characterized in that one side of the filter one 2 communicates with the water vapor remover 1, the other side of the filter one 2 communicates with the flame arrester 3, and the flame arrester 3 and the burner 11 are provided There is a concentration monitor one 5, a valve one 4 is arranged between the flame arrester 3 and the concentration monitor one 5, one end of the valve four 13 communicates with the gas storage tank 14, and the other end of the valve four 13 Set between the flame arrester 3 and the valve one 4, the valve four controller 12 is arranged between the concentration monitor one 5 and the valve four 13, and the filter is arranged between the exhaust passage 15 and the burner 11 in s...

specific Embodiment 2

[0015] Specific embodiment two, please refer to figure 1 , a new type of organic waste gas combustion purification device, comprising a water vapor remover 1, a filter 2, a concentration monitor 5, a fan 7, a filter 17, an exhaust passage 15, a burner 11 and a valve 4 13, its It is characterized in that one side of the filter one 2 communicates with the water vapor remover 1, the other side of the filter one 2 communicates with the flame arrester 3, and the flame arrester 3 and the burner 11 are provided There is a concentration monitor one 5, a valve one 4 is arranged between the flame arrester 3 and the concentration monitor one 5, one end of the valve four 13 communicates with the gas storage tank 14, and the other end of the valve four 13 Set between the flame arrester 3 and the valve one 4, the valve four controller 12 is arranged between the concentration monitor one 5 and the valve four 13, and the filter is arranged between the exhaust passage 15 and the burner 11 in s...

specific Embodiment 3

[0016] Specific embodiment three, please refer to figure 1 , a new type of organic waste gas combustion purification device, comprising a water vapor remover 1, a filter 2, a concentration monitor 5, a fan 7, a filter 17, an exhaust passage 15, a burner 11 and a valve 4 13, its It is characterized in that one side of the filter one 2 communicates with the water vapor remover 1, the other side of the filter one 2 communicates with the flame arrester 3, and the flame arrester 3 and the burner 11 are provided There is a concentration monitor one 5, a valve one 4 is arranged between the flame arrester 3 and the concentration monitor one 5, one end of the valve four 13 communicates with the gas storage tank 14, and the other end of the valve four 13 Set between the flame arrester 3 and the valve one 4, the valve four controller 12 is arranged between the concentration monitor one 5 and the valve four 13, and the filter is arranged between the exhaust passage 15 and the burner 11 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com