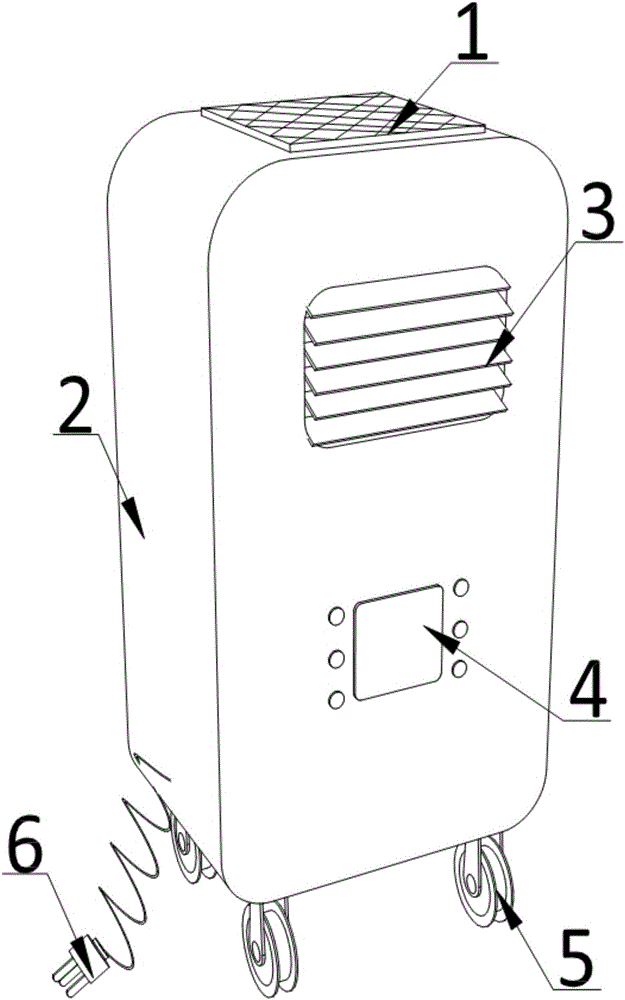

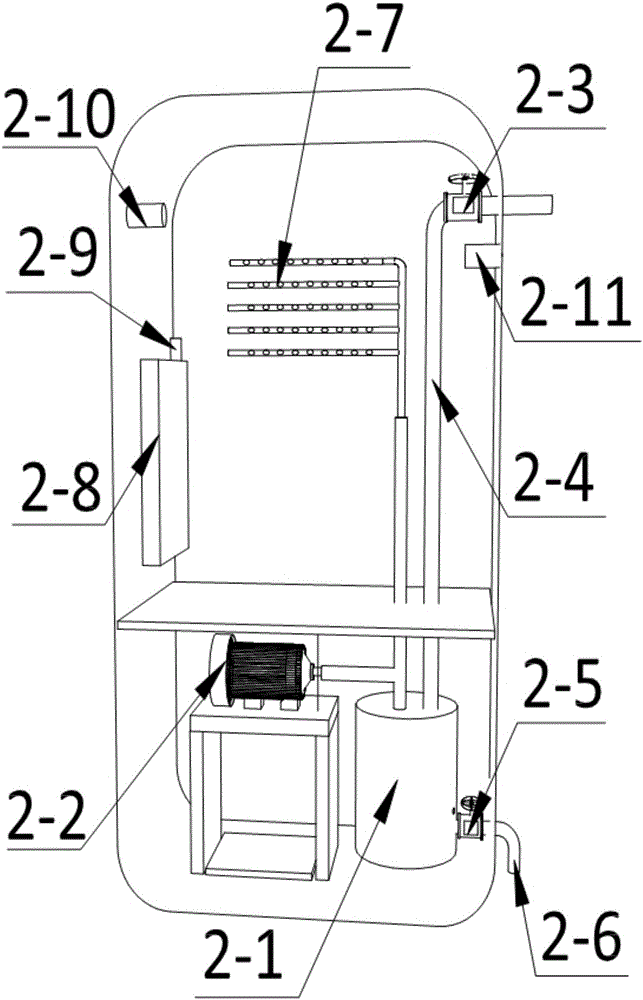

Moveable type indoor intelligent humidifier automatic control system with solar panel and working method thereof

A solar panel and automatic control system technology, which is applied in air humidification systems, heating and ventilation control systems, air conditioning systems, etc., can solve the problems of insufficient utilization of natural resources such as solar energy, high noise, and large humidification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

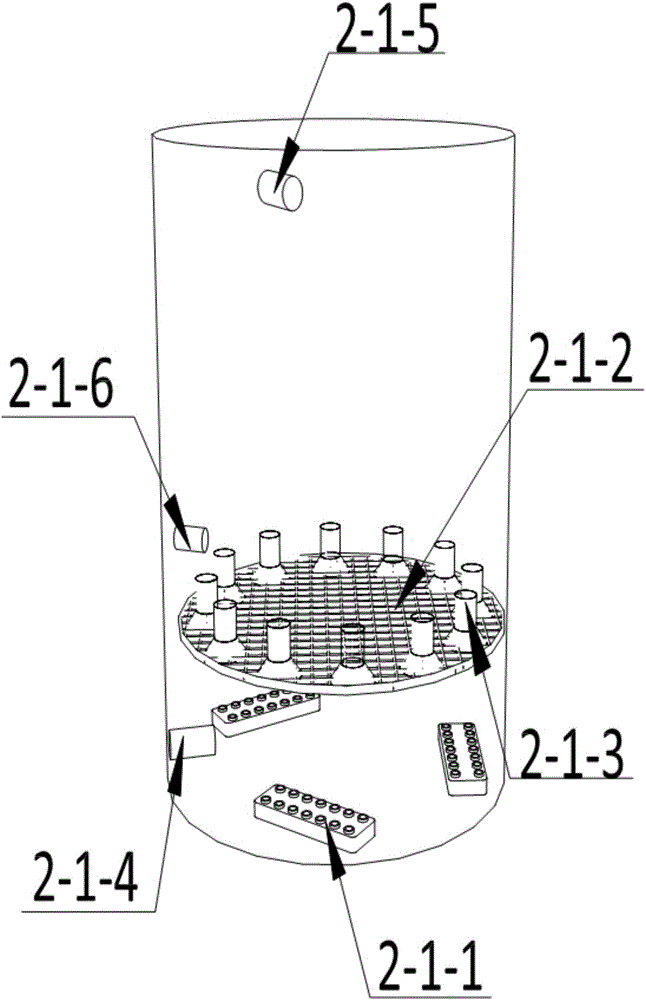

Embodiment 1

[0062] Manufacture nozzle 2-7-2 of the present invention according to the following steps, and in parts by weight:

[0063] Step 1: Add 1845 parts of ultrapure water with a conductivity of 3.28 μS / cm into the reactor, start the stirrer in the reactor at a speed of 92 rpm, and start the heating pump to raise the temperature in the reactor to 48 °C; Add 42 parts of 2-isopropyl-5-methylanisole and 58 parts of 3-phenoxybenzyl 2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylate , 13 parts of 3-fluoro-4-(4-morpholinyl)-aniline, stirred until completely dissolved, adjusted the pH value to 2.8, adjusted the stirrer speed to 115 rpm, and the temperature was 102 ° C, and the esterification reaction was carried out for 12 hours;

[0064] Step 2: Take 3-(2,2-dichlorovinyl)-2,2-dimethylcyclopropanoic acid-(1S,3S)-REL-(R)-cyano(3-phenoxyphenyl 36 parts of methyl ester, 102 parts of (RS)-α-cyano-3-phenoxybenzyl-(RS)-2,2-dichloro-1(4-ethoxyphenyl)cyclopropanecarboxylic acid Carry ou...

Embodiment 2

[0069] Manufacture nozzle 2-7-2 of the present invention according to the following steps, and in parts by weight:

[0070] Step 1: Add 2155 parts of ultrapure water with a conductivity of 4.12 μS / cm into the reactor, start the stirrer in the reactor at a speed of 122 rpm, and start the heating pump to raise the temperature in the reactor to 68 °C; Add 57 parts of 2-isopropyl-5-methylanisole, 83 parts of 3-phenoxybenzyl 2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylate , 33 parts of 3-fluoro-4-(4-morpholinyl)-aniline, stirred until completely dissolved, adjusted the pH value to 5.3, adjusted the speed of the stirrer to 158 rpm, and the temperature was 132 ° C, and the esterification reaction was carried out for 20 hours;

[0071] Step 2: Take 3-(2,2-dichlorovinyl)-2,2-dimethylcyclopropanoic acid-(1S,3S)-REL-(R)-cyano(3-phenoxyphenyl 66 parts of methyl ester, 130 parts of (RS)-α-cyano-3-phenoxybenzyl-(RS)-2,2-dichloro-1(4-ethoxyphenyl)cyclopropanecarboxylic acid Car...

Embodiment 3

[0076] Manufacture nozzle 2-7-2 of the present invention according to the following steps, and in parts by weight:

[0077] Step 1: Add 2528 parts of ultrapure water with a conductivity of 5.72 μS / cm into the reactor, start the stirrer in the reactor at a speed of 156 rpm, and start the heating pump to raise the temperature in the reactor to 86 °C; Add 79 parts of 2-isopropyl-5-methylanisole and 106 parts of 3-phenoxybenzyl 2,2-dimethyl-3-(2-methyl-1-propenyl)cyclopropanecarboxylate , 54 parts of 3-fluoro-4-(4-morpholinyl)-aniline, stirred until completely dissolved, adjusted the pH value to 7.2, adjusted the stirrer speed to 196 rpm, the temperature was 163 °C, and the esterification reaction was carried out for 28 hours;

[0078] Step 2: Take 3-(2,2-dichlorovinyl)-2,2-dimethylcyclopropanoic acid-(1S,3S)-REL-(R)-cyano(3-phenoxyphenyl ) methyl ester 92 parts, (RS)-α-cyano-3-phenoxybenzyl-(RS)-2,2-dichloro-1(4-ethoxyphenyl)cyclopropanecarboxylic acid 165 parts Carry out pulve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com