Measuring method of automatic comprehensive panel detecting device

A technology of automatic synthesis and detection device, applied in the field of comprehensive measurement, can solve the problems of only detecting the curvature of the center, low detection efficiency, and small detection range, and achieves the reduction of labor intensity of workers, comprehensive measurement parameters, and a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

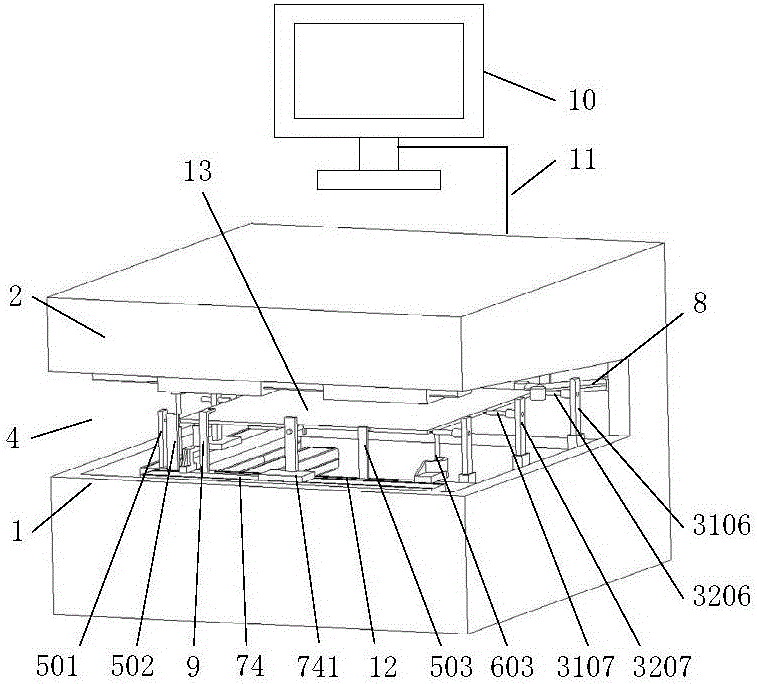

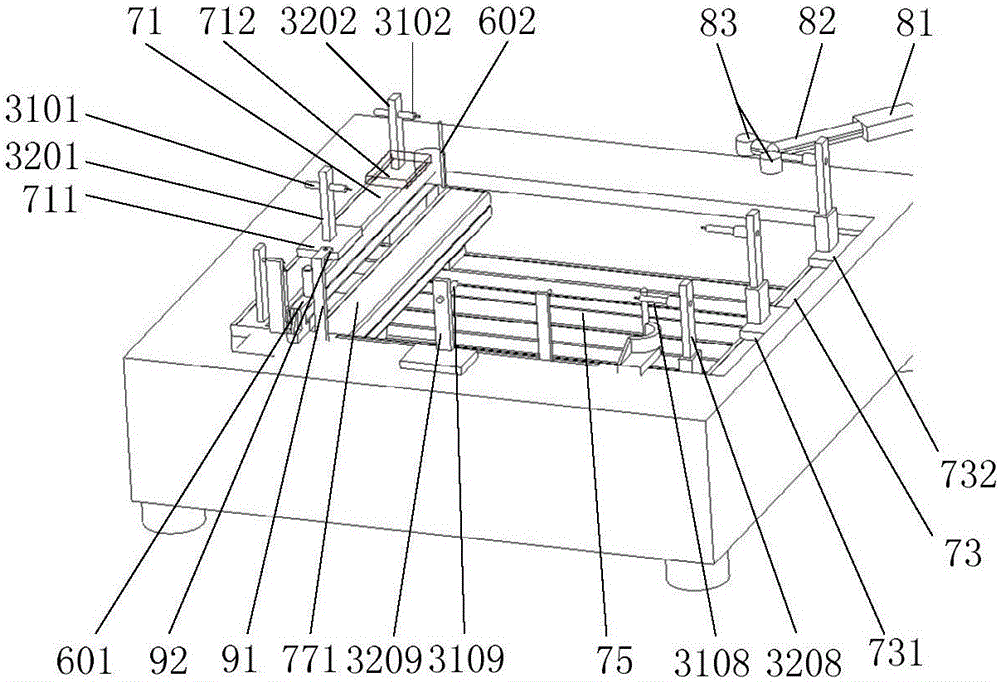

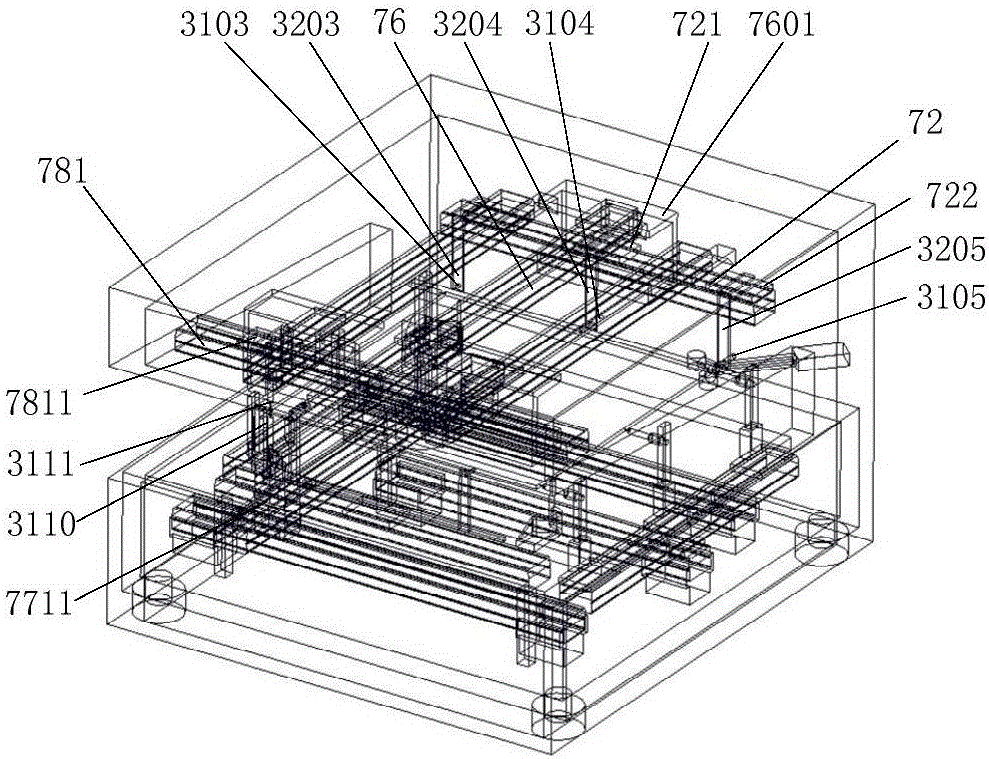

[0027] Such as Figures 1 to 6 As shown, an automatic comprehensive detection device for plates includes an inverted U-shaped body, a displacement sensor unit, a positioning unit, a displacement drive control unit, a number recognition unit, an industrial computer control and an information processing unit. The lower part of the inverted U-shaped body forms the base 1 , the upper part of the inverted U-shaped body forms the top cover 2 , and the U-shaped port 4 is used for the entry and exit of the measured piece. The base 1 is provided with movable support pins and grooves 12 of the workpiece 13 to be measured, and the positioning unit and the code recognition unit are connected to the industrial computer through data lines, wherein the base 1 is provided with workpiece support pins 601-603; The sensing unit includes displacement sensors 3101-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com