Device and method for measuring thermal conductivity of porous powder material on basis of one-dimensional thermal conductive principle

A technology of porous powder and measuring device, applied in the direction of thermal development of materials, etc., can solve the problems of high cost and low accuracy of measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

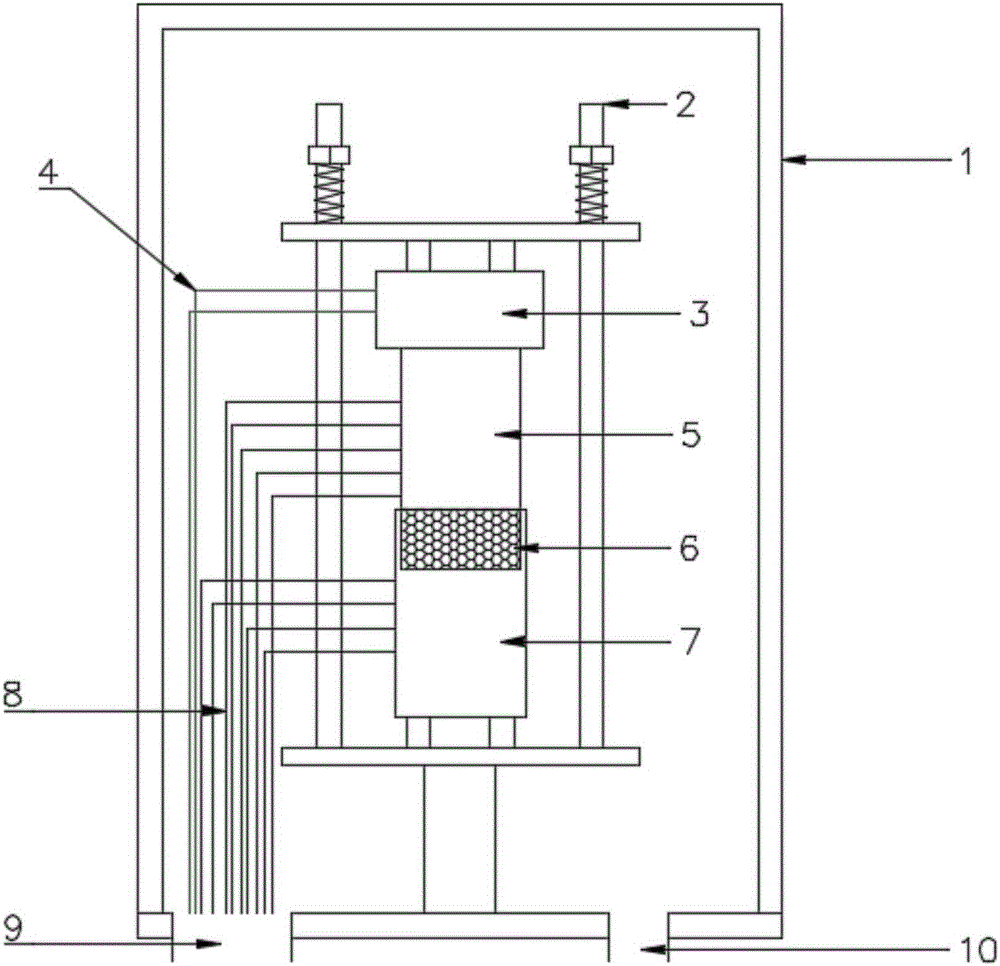

[0028] like figure 1 Shown is a structural diagram of an embodiment of the present invention, including a vacuum chamber 1, the chamber shell material of the vacuum chamber 1 is stainless steel, the inner wall is attached with a radiation screen, and there are two holes at the bottom of the chamber, which are the aviation plug interface 9 and the vacuum chamber. Molecular pump interface 10. The inside of the cavity includes a support table 2, a heating unit 3, a heating unit power lead 4, a first known sample 5, a circular ring 6, a second known sample 7, and a thermocouple 8; wherein:

[0029] The thermocouple 8 is a K-type thermocouple with a diameter of 0.8 mm. In this embodiment, 8 thermocouples are used to weld the surfaces of the first and second known samples at an interval of 4 mm by soldering to realize multi-point temperature collection. , The output end of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com