Carbon fiber electric field sensor structure and preparation method

An electric field sensor and carbon fiber technology, applied in the direction of electrostatic field measurement, etc., can solve the problems of short service life, troublesome transportation, complicated maintenance, etc., and achieve the effects of long service life, simple and convenient transportation process, and stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

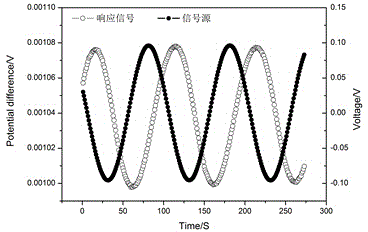

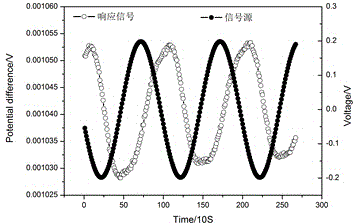

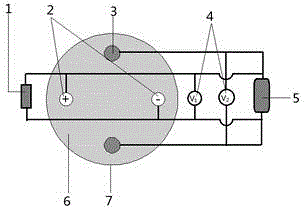

[0033] Such as figure 1 As shown, the present invention relates to a carbon fiber electric field sensor structure and preparation method. The effective length of the carbon fiber bundle 2 is 220mm, and the end of the carbon fiber bundle is cured inside the curing cavity 3 with epoxy resin 9; Ultrasonic cleaning with NaOH solution, HCl solution, and distilled water; then plate a layer of metallic silver 8 on the cross-section of the curing cavity, weld the wire 6 on the silver layer, and then fill the solder joint 4 with epoxy resin to seal the solder joint 4 with a watertight cover 5; The microporous tube 10 is screwed to the bottom of the curing chamber, the inner carbon fiber is fixed with a filler 11, and the bottom cover 1 is screwed on, and the carbon fiber electric field sensor is successfully prepared. This carbon fiber electric field sensor does not require long-term maintenance in seawater, has a long service life, is easy to transport, is extremely stable, and has a ...

Embodiment 2

[0035] Such as figure 1 As shown, the present invention relates to a carbon fiber electric field sensor structure and preparation method. The effective length of the carbon fiber bundle 2 is 220mm, and the end of the carbon fiber bundle is cured inside the curing cavity 3 with epoxy resin 9; Ultrasonic cleaning with NaOH solution, HCl solution, and distilled water; then plate a layer of metal copper 8 on the cross section of the curing chamber, weld the wire 6 on the copper layer, and then fill the watertight cover 5 with epoxy resin to seal the solder joint 4; The microporous tube 10 is screwed to the bottom of the curing chamber, the inner carbon fiber is fixed with a filler 11, and the bottom cover 1 is screwed on, and the carbon fiber electric field sensor is successfully prepared. This carbon fiber electric field sensor does not require long-term maintenance in seawater, has a long service life, is easy to transport, is extremely stable, and has a good response to electri...

Embodiment 3

[0037] Such as figure 1As shown, the present invention relates to a structure and preparation method of a carbon fiber electric field sensor. The electric field sensor structure mainly includes five parts: carbon fiber bundle 2, carbon fiber curing cavity 3, watertight cover 5, microporous tube 10, and bottom cover 1. Among them, the carbon fiber curing cavity, watertight cover and bottom cover are made of plexiglass. One end of the carbon fiber bundle is cured inside the curing chamber with epoxy resin 9. After grinding, a layer of metal 8 is coated on the cross-section of the carbon fiber bundle, and then the wire 6 is welded to the surface of the metal layer. The solder joint 4 is sealed by a watertight cover, and the wire A watertight joint 7 is installed at the lead-out part, and the microporous tube 10 is connected to the bottom of the curing chamber by threads, and filled with a filler 11 to fix the carbon fiber bundle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com