Bi-telecentric prime lens

A fixed focus lens, double telecentric technology, applied in optical components, instruments, optics, etc., can solve the problems of large size, high production cost, and heavy weight of telecentric lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

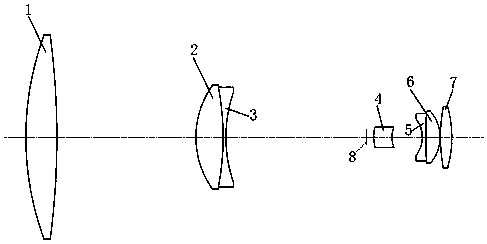

[0032] Below in conjunction with accompanying drawing, the preferred mode of the present invention is further elaborated: as figure 1 As shown, this implementation mode introduces and illustrates the solution of the present invention in a specific form when the object distance of the bi-telecentric fixed-focus lens is 260 mm. A double-telecentric fixed-focus lens, which is sequentially provided with a first single positive spherical lens 1, a second single positive spherical lens 2, a third single negative spherical lens 3, a fourth single negative spherical lens 4, The fifth single negative spherical lens 5 , the sixth single positive spherical lens 6 and the seventh single positive spherical lens 7 . The first single positive spherical lens 1, the second single positive spherical lens 2, the sixth single positive spherical lens 6, and the seventh single positive spherical lens 7 are biconvex positive lenses; the dispersion problem in the optical system is reduced. The mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com