Anti-twisting cable with high mechanical strength

A mechanical strength and cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of inability to meet the laying requirements of narrow spaces, inability to resist external electromagnetic wave interference, poor elasticity and flexibility, etc. Corrosion performance, effect of increasing waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

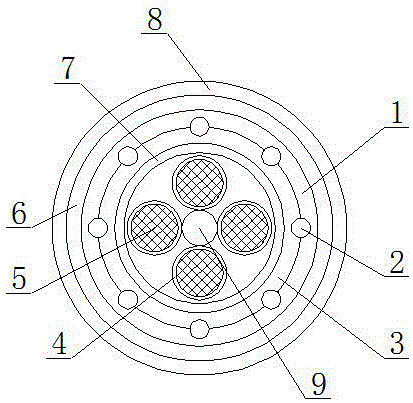

[0026] Such as figure 1 As shown, in this embodiment, a torsion-resistant cable with high mechanical strength includes an outer sheath 1, an inner sheath 3 arranged in the outer sheath 1, and several cable sheaths 4 arranged in the inner sheath 3 And the cable core 5 arranged in the cable sheath 4, the inner surface of the outer sheath 1 is provided with several A grooves, the outer surface of the inner sheath 3 is provided with B grooves corresponding to the A grooves one by one, and the A grooves and the B grooves The grooves cooperate to form a cavity, and the reinforcement 2 is installed in the cavity. By arranging the reinforcement 2 in the cavity, the reinforcement 2 can act as a hindrance, thereby preventing the relative rotation of the outer sheath 1 and the inner sheath 3. Thereby improving the torsion resistance of the present invention, avoiding wear and tear between the inner sheath 3 and the outer sheath 1, prolonging the service life of the present invention, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com