Oil seal cooling device applied to vent hole of gearbox

A technology for cooling devices and gearboxes, which is applied to transmission parts, gear lubrication/cooling, belts/chains/gears, etc. It can solve the problems of high processing costs and achieve the effect of compact structure, simple structure and extended flow distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

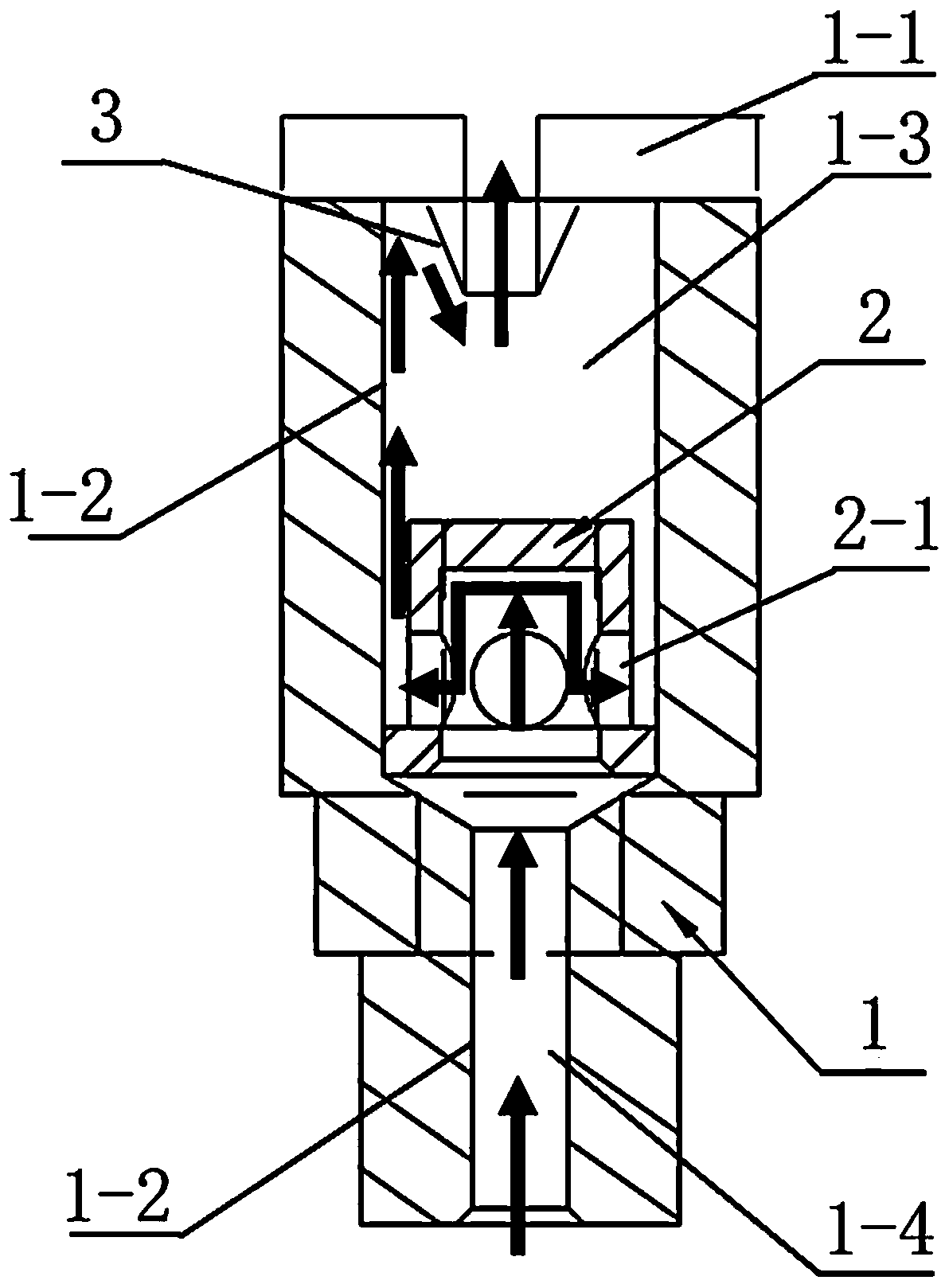

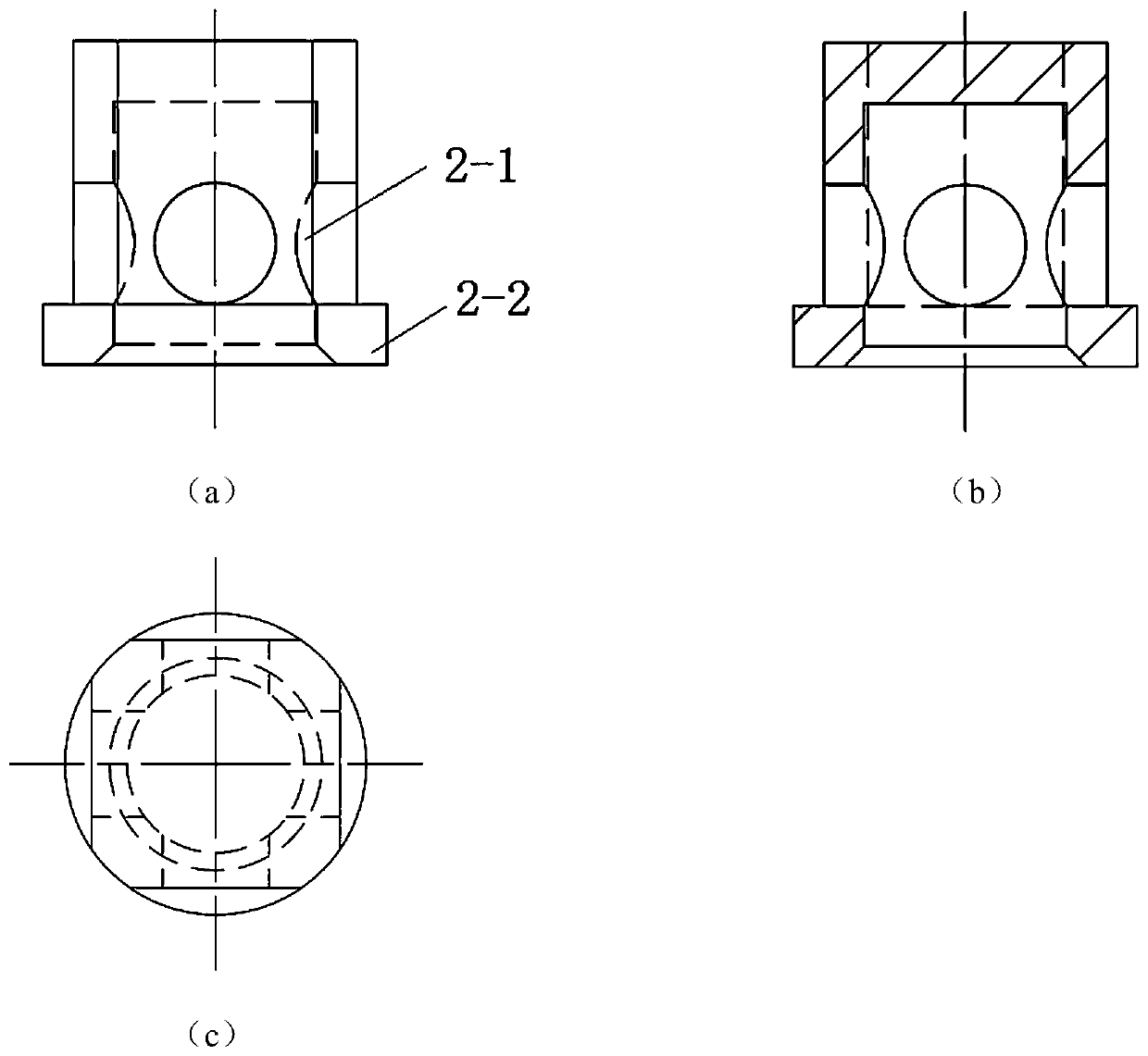

[0021] The oil seal cooling device of the present invention applied to the air hole of the gearbox comprises a mounting column 1 and an insert 2 structurally.

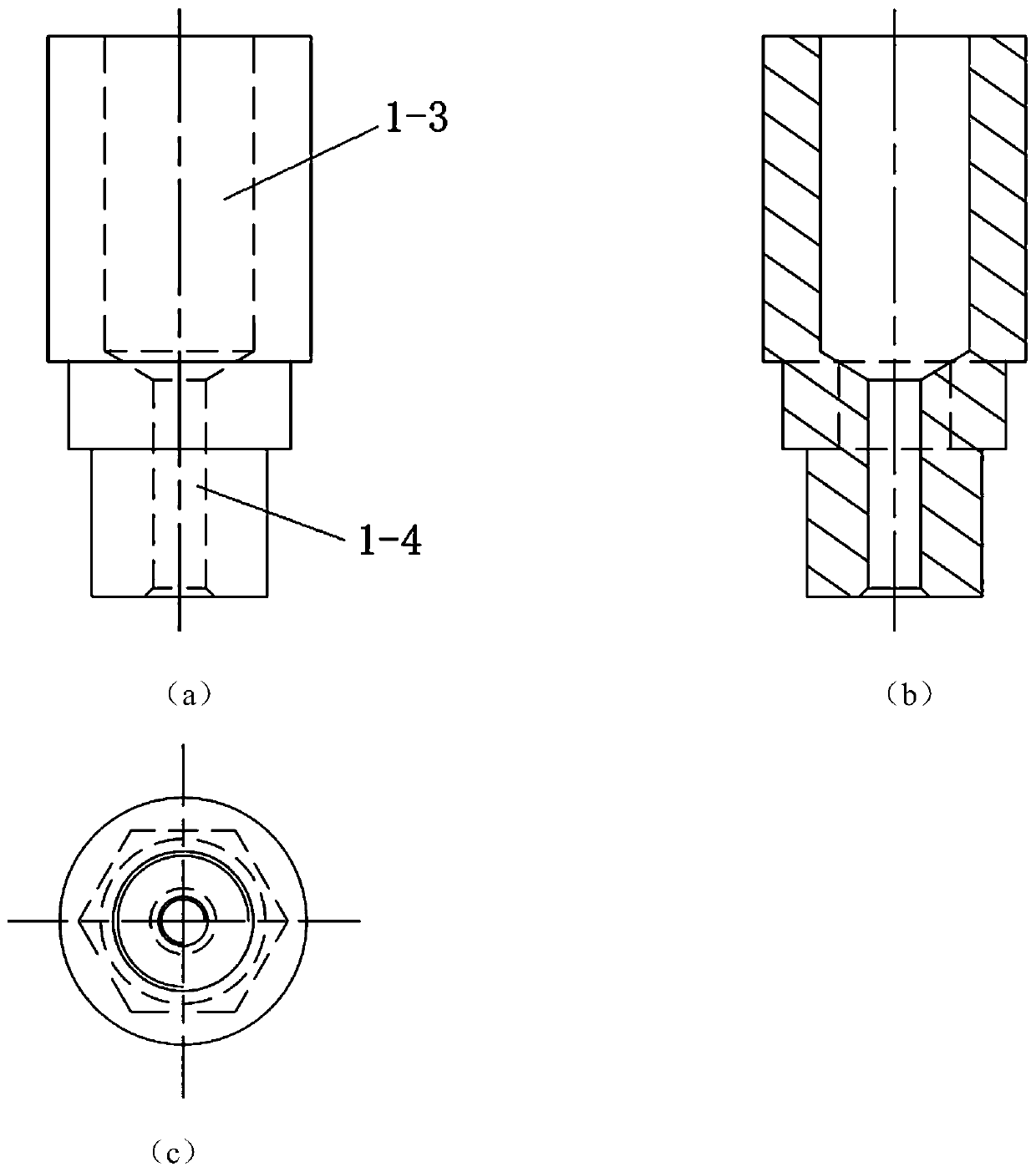

[0022] see figure 2 (a), figure 2 (b), figure 2 (c), the outer contour of the mounting column 1 is stepped and columnar, and the inside is processed with through holes, which are integrally formed or assembled by splicing multiple parts. The through hole of the mounting column 1 is connected to the air hole of the gearbox. The through hole is a variable-diameter channel and the upper part has a larger diameter, including the insertion hole 1-3 and the gearbox docking hole 1-4. From the upper hole to the The insert 2 is loaded into the through hole of the installation column 1, and the insert 2 is stuck in the middle of the through hole of the installation column 1. The two ends of the gearbox b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com