Flexible package lithium ion battery and manufacturing method thereof

A lithium-ion battery and a manufacturing method technology, which are applied in the manufacture of electrolyte storage batteries, battery pack components, and final product manufacturing, etc., can solve the problems of external PTC solder joints falling off, easy loss of protection function, short circuit of external tabs, etc. The effect of stable and reliable fixation, reliable protection and not easy to be damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] This example will specifically explain the manufacturing method of the soft-packaged lithium-ion battery disclosed in the present invention, which is equivalent to explaining the structure of the soft-packaged lithium-ion battery. The manufacturing method specifically includes the following steps:

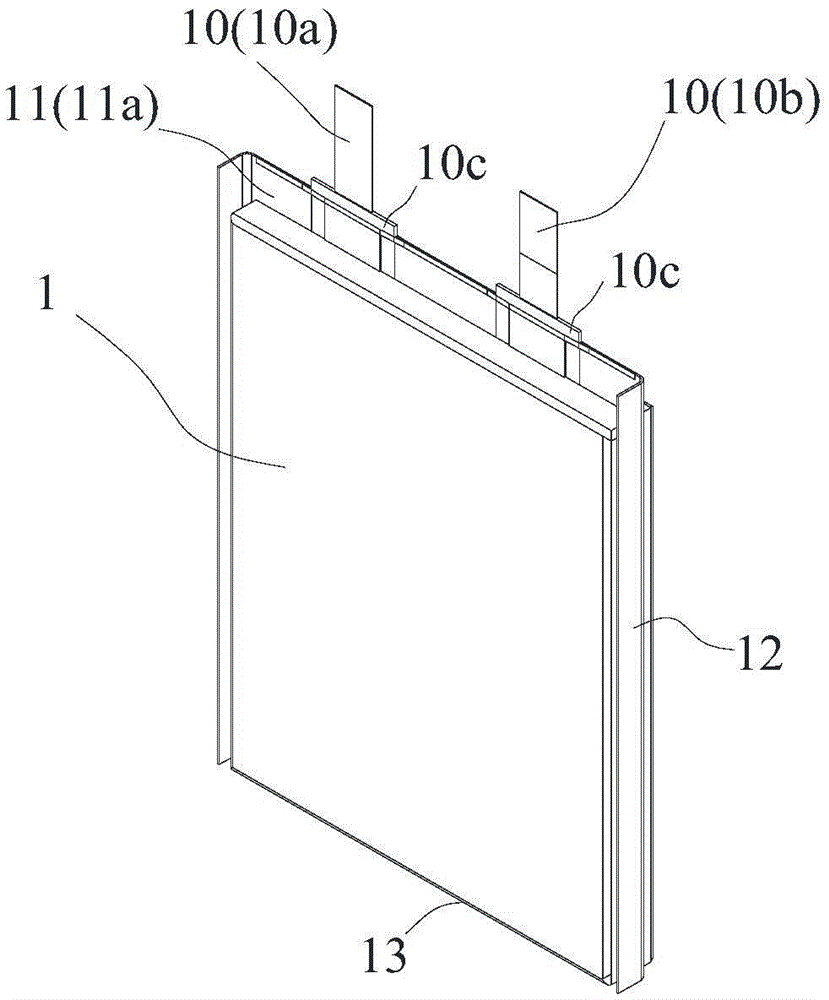

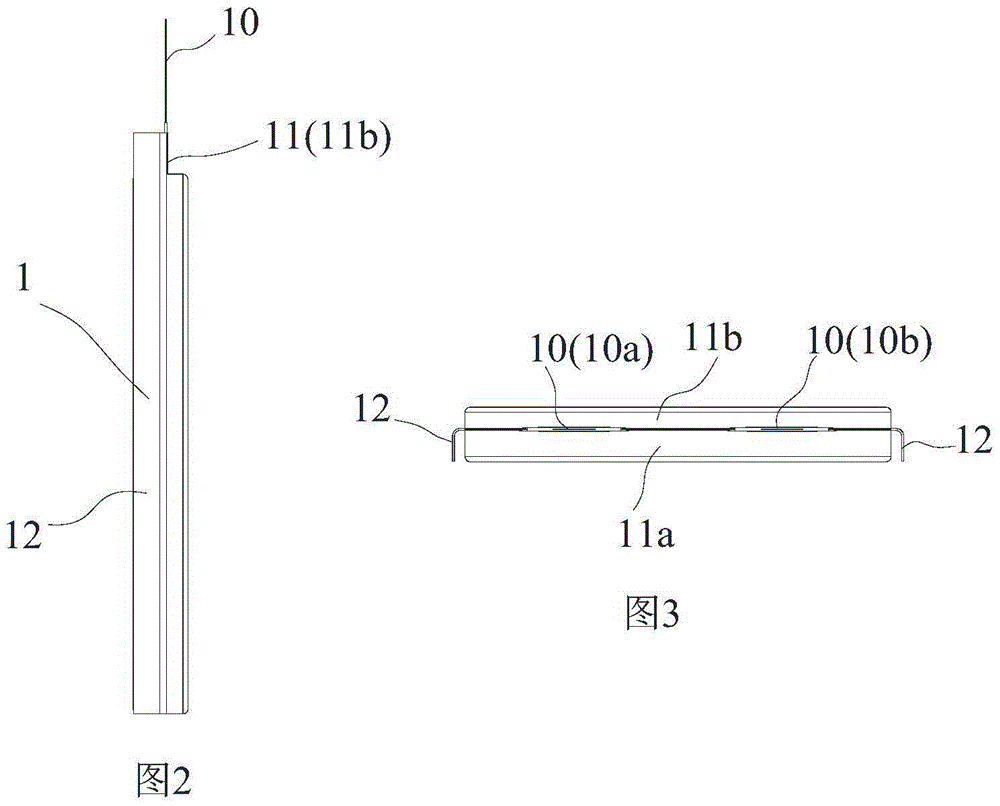

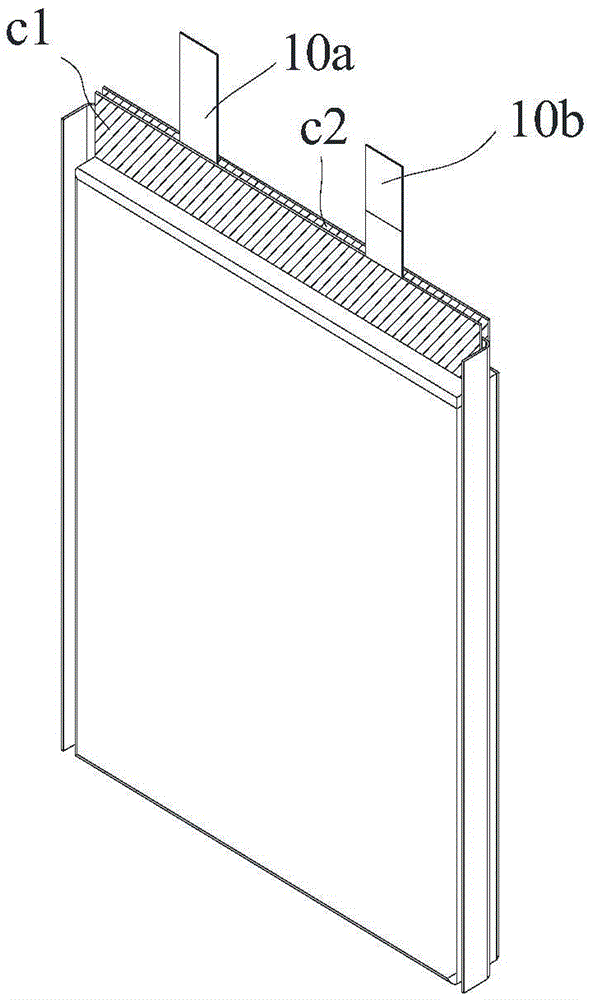

[0075] S1. The manufacturing steps of the soft-packed battery cell: manufacture the core and the electrolyte, and use the aluminum-plastic composite film to make the battery shell; package the roll core and the electrolyte in the battery shell, and manufacture the soft-packed battery; The structure of the soft-packed battery is as follows: Figure 1-Figure 3 shown;

[0076] The cell casing includes a bottom seal 13 at the bottom, side seals 12 on both sides and a top seal 11 at the top; the core is provided with tabs 10, and the tabs 10 include a first pole Ear 10a and second pole ear 10b, the first pole ear 10a and the second pole ear 10b are drawn out from the top sealing...

Embodiment 2

[0111] According to the manufacturing method of the soft-package lithium-ion battery provided in the above-mentioned embodiment 1, this example explains the structure of the soft-package lithium-ion battery for comparison. Please refer to the drawings and descriptions of the drawings for understanding.

[0112] This example provides a soft package lithium ion battery, including a soft package battery cell 1, a PTC2, a first electrode sheet T1, a second electrode sheet T2 and a soft package shell made of aluminum-plastic composite film; the soft package battery cell 1 and the PTC2 are packaged in the soft case;

[0113] The soft pack cell 1 includes a cell shell made of an aluminum-plastic composite film and a coil core and an electrolyte packaged in the cell shell; the structure of the soft pack cell 1 is as follows: Figure 1-Figure 3 As shown; the cell housing includes a bottom seal 13 at the bottom, side seals 12 on both sides and a top seal 11 at the top; the core is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com