Heat exchange module and electronic device applying heat exchange module

A technology for heat exchange modules and electronic devices, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of unstable heat dissipation core quality, insufficient rigidity, easy bending deformation, etc., and achieve the effect of saving cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

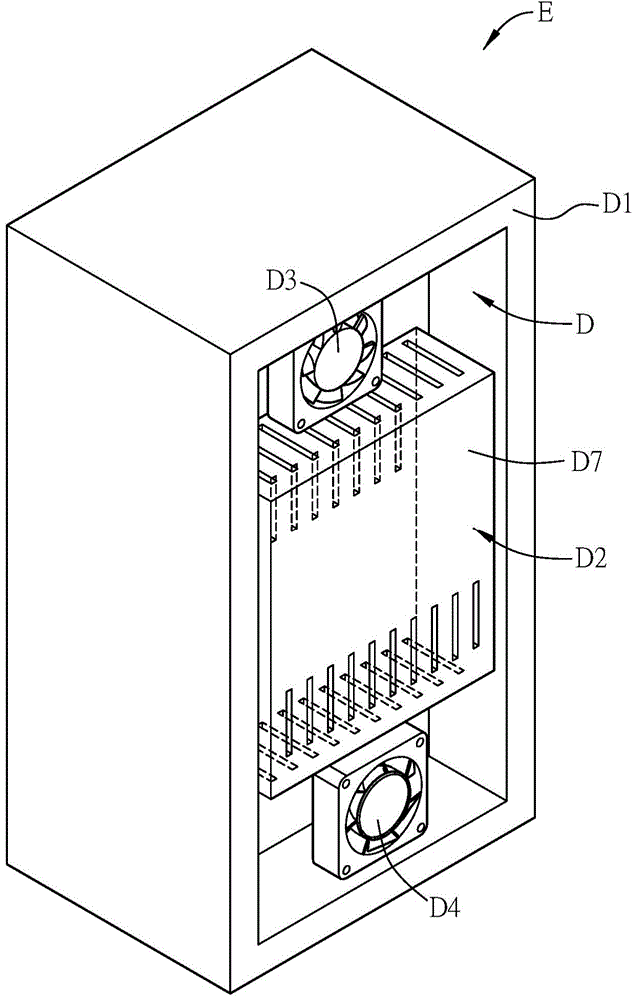

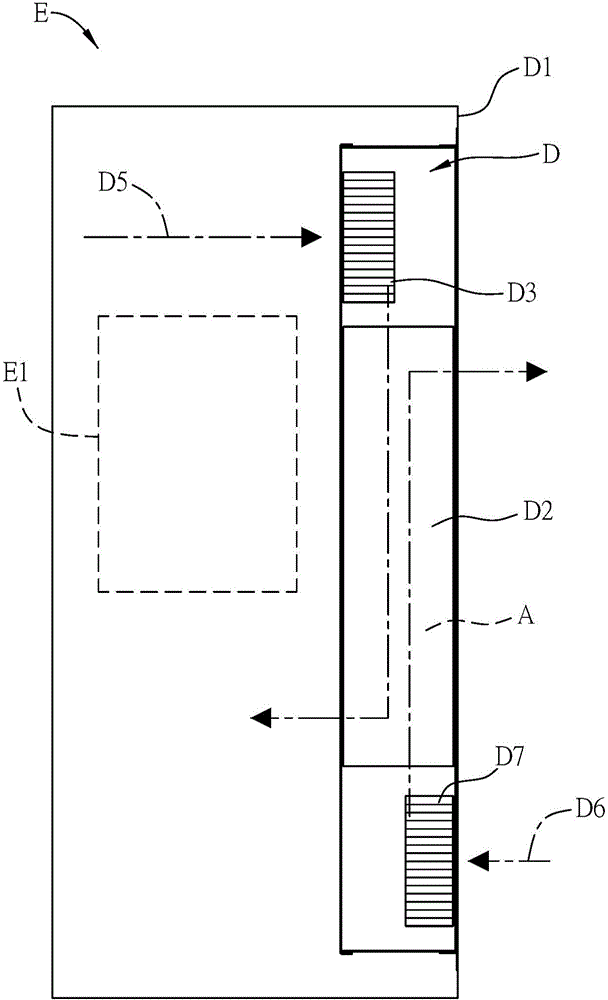

[0067] A preferred heat exchange module according to the present invention and an electronic device using the same will be described below with reference to related drawings, wherein the same components will be described with the same reference symbols.

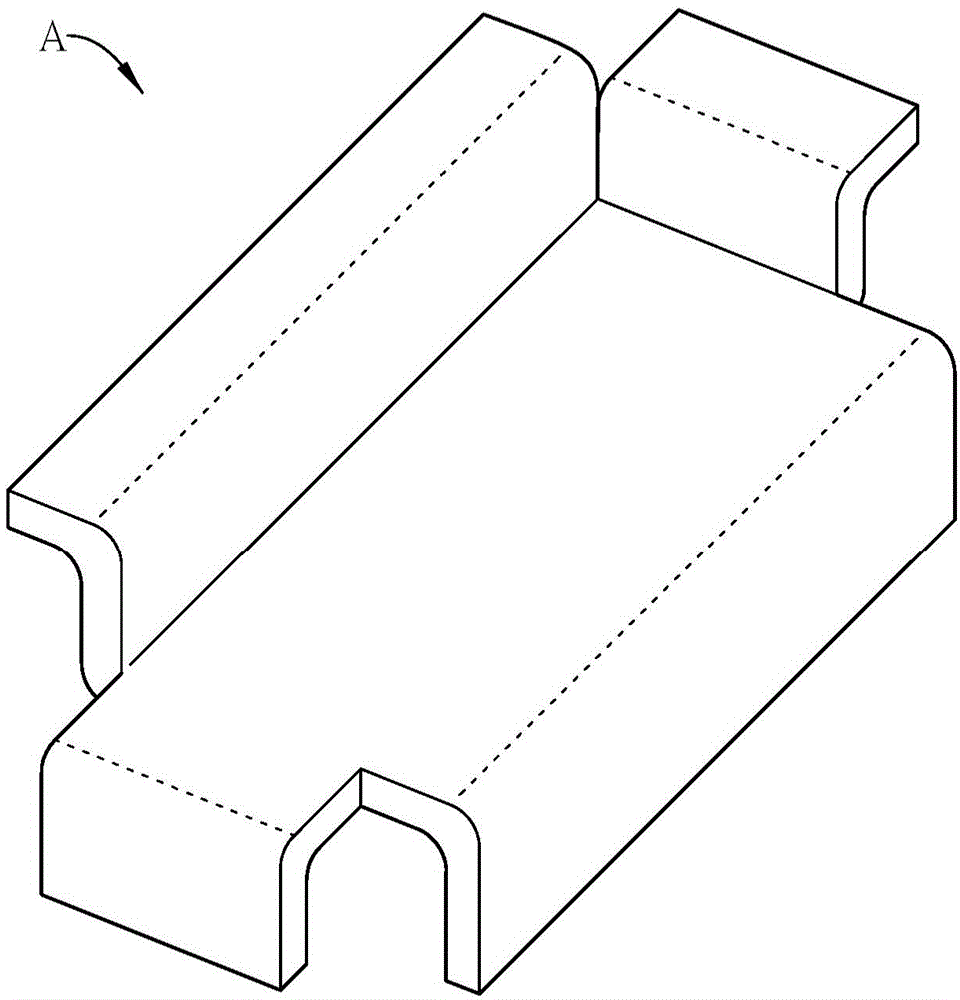

[0068] Figure 2A It is a schematic diagram of the appearance of a heat exchange module in a preferred embodiment of the present invention, Figure 2B for Figure 2A A schematic diagram of the partial appearance of the heat exchange module shown, Figure 2C for Figure 2A Partially exploded schematic diagram of the heat exchange module shown, please also refer to Figure 2A , Figure 2B and Figure 2C As shown, the heat exchange module 1 includes a housing 10, and a plurality of first air guides 11, a plurality of second air guides 12, a plurality of first spacers 13 and a plurality of air guides accommodated in the housing 10. the second spacer 14 . In this embodiment, the casing 10 is a cuboid structure, which has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com