Composite metal catalyst composition, and method and apparatus for preparing 1,4-cyclohexanedimethanol using same

一种环己烷二甲醇、金属催化剂的技术,应用在羟基化合物制备、有机化合物的制备、金属/金属氧化物/金属氢氧化物催化剂等方向,能够解决环己烷二甲醇产率下降、实际应用困难、商业化困难等问题,达到简化反应过程、改善效率和经济效率、增加效率和经济效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

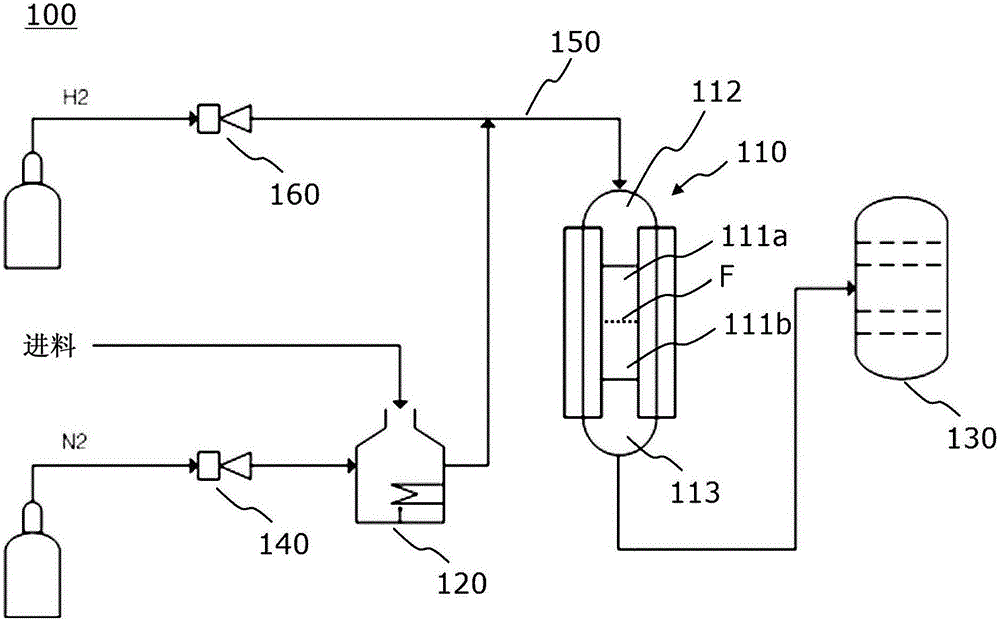

Image

Examples

preparation example Construction

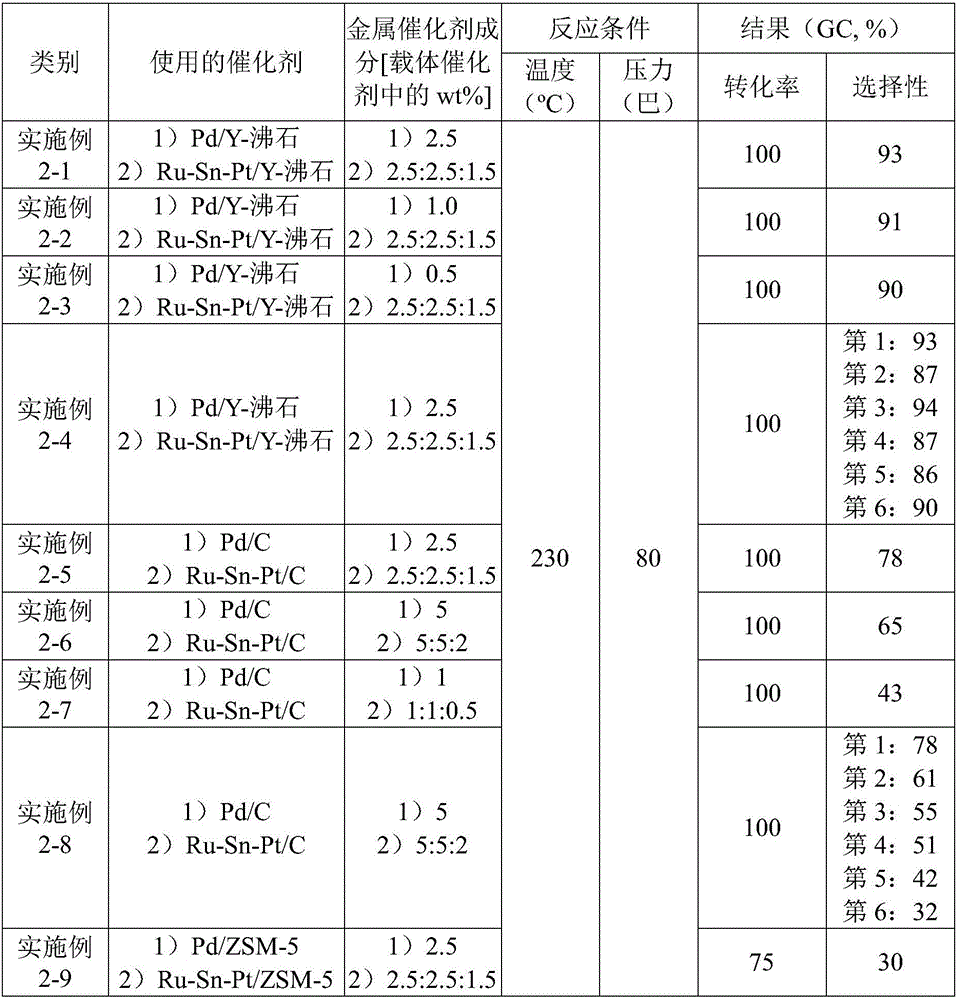

[0061] The method for preparing 1,4-cyclohexanedimethanol according to the present invention may include the step of reducing the reduction product of terephthalic acid in the ratio of 1:0.8 to 1.2:0.2 to 0.6, For example, obtained by the step of reducing terephthalic acid in the presence of a second metal catalyst comprising a ruthenium (Ru) compound, a tin (Sn) compound, and a platinum (Pt) compound in a weight ratio of 1:0.9 to 1.1:0.3 to 0.55 .

[0062] Ruthenium contained in the second metal catalyst appears to convert dicarboxylic acids into primary alcohols, tin appears to increase the selectivity of alcohols as synthesis products, and platinum appears to suppress side reactions by increasing the catalyst's activity.

[0063]When the reduction product of terephthalic acid comprising 1,4-cyclohexanedicarboxylic acid is reduced in the presence of the second metal catalyst, a reaction product comprising 1,4-cyclohexanedimethanol may be formed.

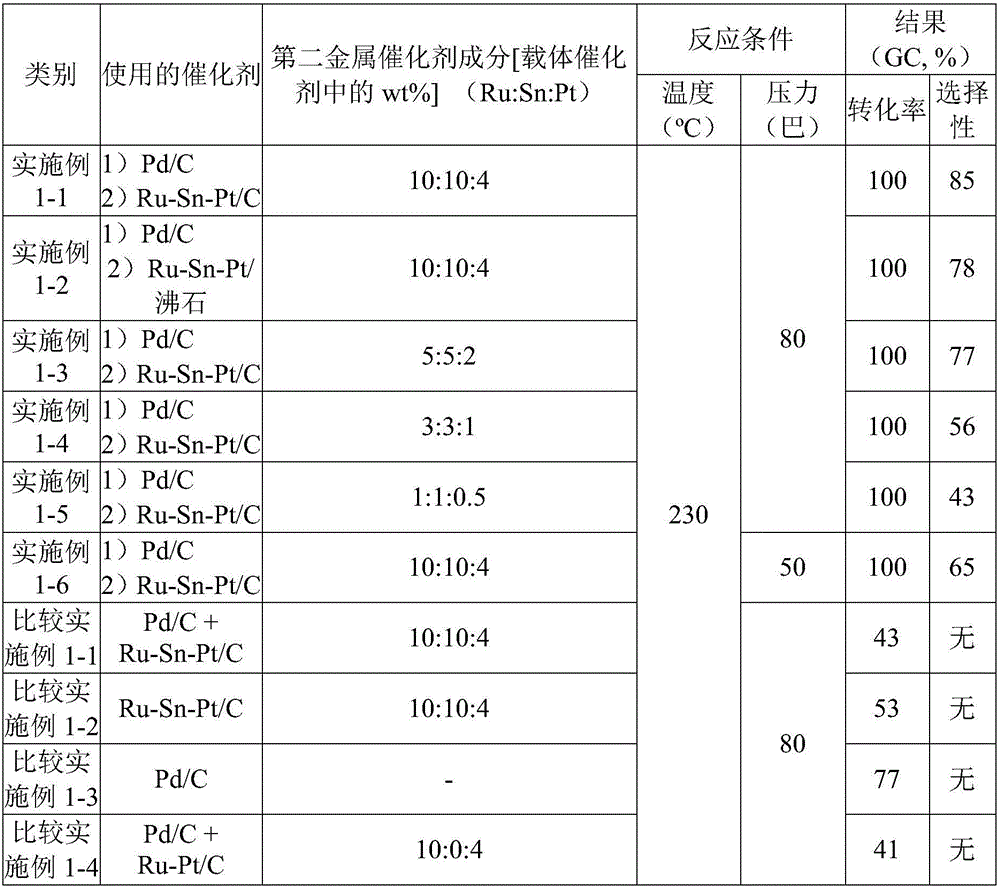

[0064] As demonstrated in ...

Embodiment 1

[0098] Example 1: Direct conversion of terephthalic acid to 1,4-cyclohexanedimethanol using an activated carbon supported catalyst reaction

preparation Embodiment 1-1

[0099] Preparation Example 1-1: Preparation of the first metal catalyst

[0100] 10 g of activated carbon (Aldrich) and 60% nitric acid aqueous solution were charged into a 500 ml beaker, and the mixture was stirred after the temperature was increased to 80°C. After the stirring was completed, the activated carbon was washed with ion-exchanged water, and then dried under reduced pressure. Activated carbon and palladium chloride were dissolved in aqueous hydrochloric acid in a 500 ml beaker, and then the water was removed by evaporation to obtain a residue. The obtained residue was dried under reduced pressure, and then sintered at a temperature of 300° C. for 3 hours under atmospheric pressure to prepare a first metal catalyst containing activated carbon impregnated with 0.5 wt % of palladium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com