Thermoelectric conversion material and thermoelectric conversion element

A thermoelectric conversion material and conductivity technology, applied in the direction of electrical components, thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve problems such as no guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0174] Hereinafter, the present invention will be described in more detail based on examples. However, the following examples do not limit the technical scope of the present invention in any way.

Synthetic example 1

[0175] (Synthesis Example 1) (6,20-Di(dodecyl)-29H,3H-tetrabenzo[b,g,l,q]porphyrin)

[0176]

[0177] Dipyrromethane (0.30 g, 1.0 mmol) was added to the reaction vessel replaced with argon, and dissolved in dichloromethane (200 ml). Argon gas was bubbled thereinto for 10 minutes. Next, tridecanal (0.3ml, 1.1nnol) and trifluoroacetic acid (TFA) (2 drops) were added sequentially, and stirred for 17 hours in the dark. 2,3-Dichloro-5,6-dicyano-p-benzoquinone (DDQ) (0.35 g) was added thereto, followed by further stirring for 2 hours. After completion of the reaction, the solvent was removed until the volume of the solution became half, and alumina column chromatography (chloroform) was performed. Further, purification was performed by silica gel column chromatography (dichloromethane) and GPC, and finally recrystallization (chloroform / methanol) was performed to obtain the target compound as a reddish-brown solid. Yield: 80% (389mg, 0.405mmol)

[0178] 1 H NMR (400MHz.CDCl ...

Synthetic example 2

[0181] (Synthesis Example 2) C 12 h 25 -H 2 BP

[0182]

[0183] The porphyrin obtained above was heated in a glass tube oven in vacuum at 200° C. for 30 minutes, whereby benzoporphyrin was obtained as a green solid.

[0184] 1 H NMR (400MHz.CDCl 3 ): (m, 2H), 9.27(m, 4H), 9.09-8.89(m, 4H), 8.09(m, 8H), 4.68-4.22(m, 4H), 2.67-2.32(m, 4H), 2.04(m , 4H), 1.76-1.25 (m, 32H), 0.92 (m, 6H), -2.76 (brs, 2H) ppm.

[0185] HRMS (MALDI-TOF): m / z=846.5595, C 60 h 70 N 4 Calculated value: 846.5600[M] + .

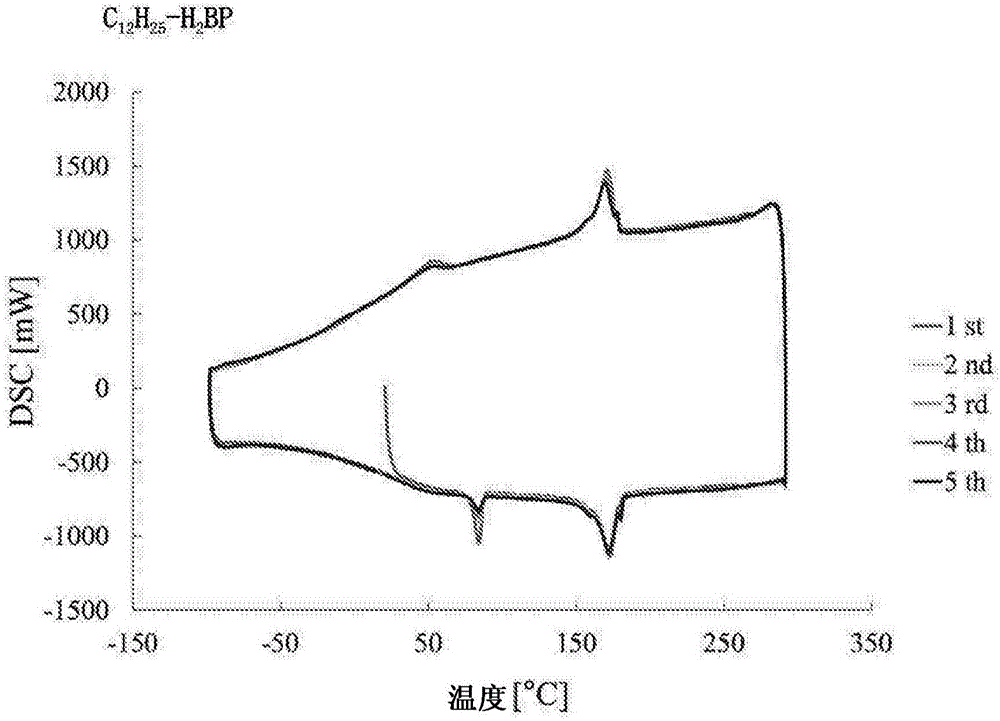

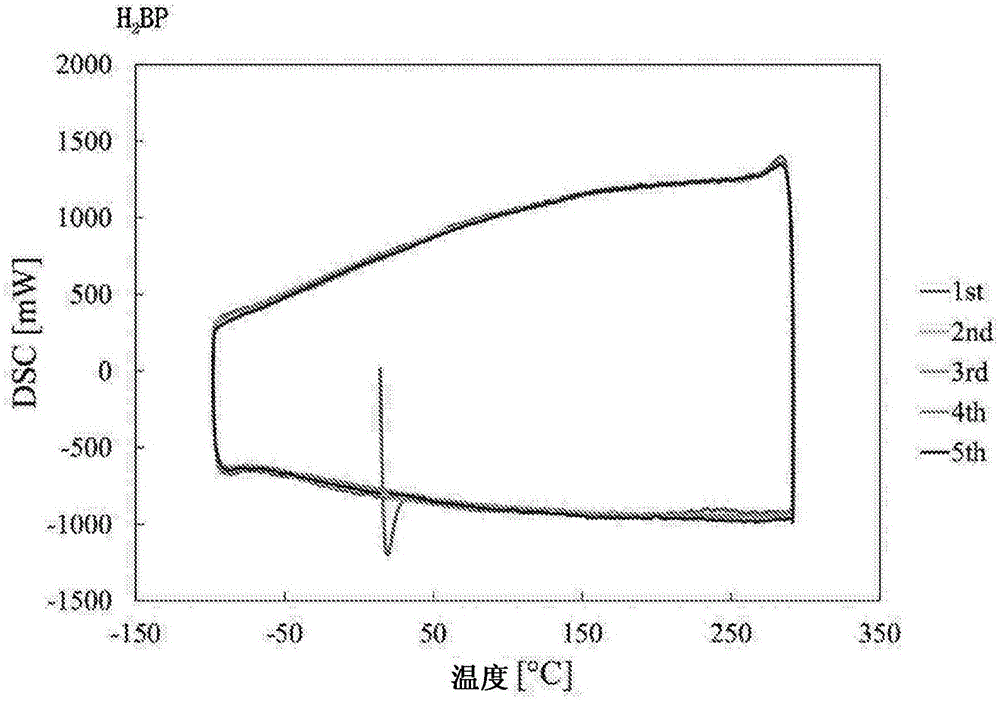

[0186] Such as figure 2 As shown, sharp and broad peaks were observed at 320-360K by DSC (170-570K), and a peak was observed around 440K, indicating that a structural phase transition occurred.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com