Waterproof breathable shoe sole

A waterproof, breathable, air-venting technology, which is applied to shoe soles, footwear, applications, etc., can solve the problems of inability to guarantee water filtration, limited space capacity of hot and humid air, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

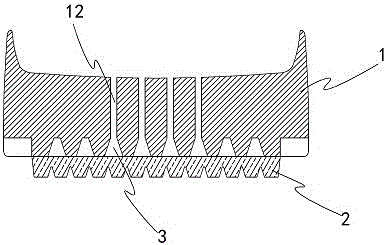

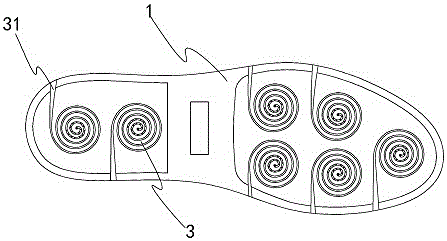

[0025] refer to Figure 1 to Figure 3 , what embodiment 1 discloses is that a waterproof and breathable sole comprises a midsole 1 and a rubber bottom sheet 2 attached to the lower surface of the midsole, the lower surface of the midsole 1 is provided with a ventilation groove, and the ventilation groove is formed by A ring-shaped thread groove 3 formed by turning and winding from outside to inside, the groove cross section of the ring-shaped thread groove 3 is trapezoidal, and the groove depth of the ring-shaped thread groove 3 is 3.5mm , the width is 3mm, and the distance between adjacent turns of the ring-shaped thread groove 3 is 8mm; the outer end of the ring-shaped thread groove 3 is provided with a ventilation notch 31 extending to the outside of the midsole; There are multiple ring-shaped thread grooves 3, and each ring-shaped thread groove 3 is arranged in an array on the sole and heel of the midsole 1; the corresponding ring-shaped thread grooves on the upper surface...

Embodiment 2

[0027] refer to Figure 4 to Figure 6 , the structure of embodiment 2 is almost the same as that of embodiment 1, the difference is that in embodiment 2, the ring-shaped threaded groove 3 is arranged on the upper surface of the rubber base 2; and the lower surface of the rubber base 2 is provided with anti-skid patterns; The anti-slip pattern includes a plurality of quadrilateral anti-slip structures 21, the four corners of the quadrilateral anti-slip structures 21 are respectively provided with hexagonal anti-slip blocks, and connecting blocks are provided between adjacent hexagonal anti-slip blocks. Anti-slip strips are provided with triangular anti-slip blocks between adjacent connected anti-slip bars, and anti-slip grooves are provided on the surface of the triangular anti-slip blocks; adjacent quadrilateral anti-slip structures 21 share a connection anti-slip strip.

Embodiment 3

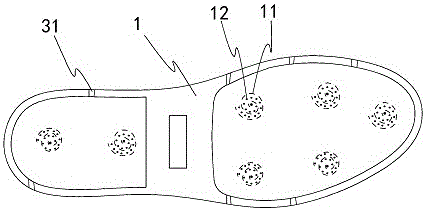

[0029] refer to Figure 7 , the structure of embodiment 3 is almost the same as that of embodiment 1, the difference is that there are only two ring-shaped thread grooves 3 in embodiment 3, and the number of turns of the two ring-shaped thread grooves 3 is respectively covered on the sole of the midsole 1 and heel.

[0030] In summary, the waterproof and breathable sole designed above has a simple structure, is convenient to manufacture, can effectively take into account both breathability and waterproof effects, and has strong practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com