Composite barium sulfate crystallization apparatus

A technology of crystallization device and barium sulfate, applied in the field of compound crystallization device, can solve the problems of large number of crystallization devices, difficult to effectively control the crystallization supersaturation, continue crystallization, etc., to improve the crystallization process and the thoroughness, thoroughness and efficiency. Simple effect of crystallization process, structure and working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

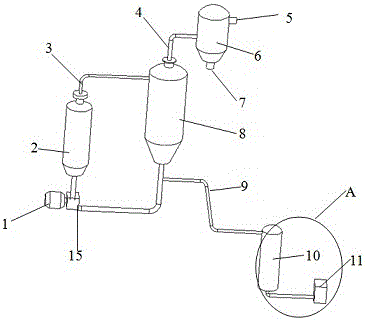

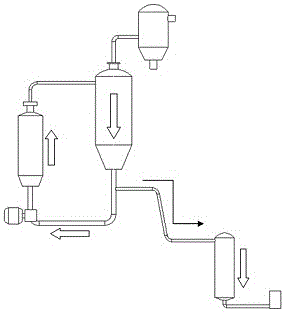

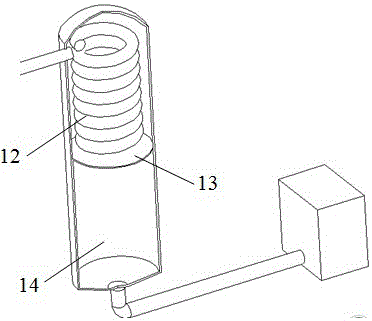

[0021] Compare below figure 1 -3 explains that because the working environment in the factory area is relatively harsh, the connection of each part should be checked before the device works, close the valve provided on the concentrated material liquid delivery pipe 9, add the barium sulfate solution to be crystallized in the main body 8, and then Start the servo motor 1, the servo motor 1 drives the water pump 15 to move, observe the test run situation, and the device completes the preparatory work so far.

[0022] When the device is working, the crystallized barium sulfate solution is placed inside the main body 8, and the servo motor 1 transports the barium sulfate solution to the inside of the heat exchanger 2 to exchange heat with water vapor through the water pump 15, and then flows into the main body 8 again after the heat exchange heats up, so that Continuous circulation, after the barium sulfate solution boils, the water vapor flows into the condenser 6 through the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com